Model 7475A

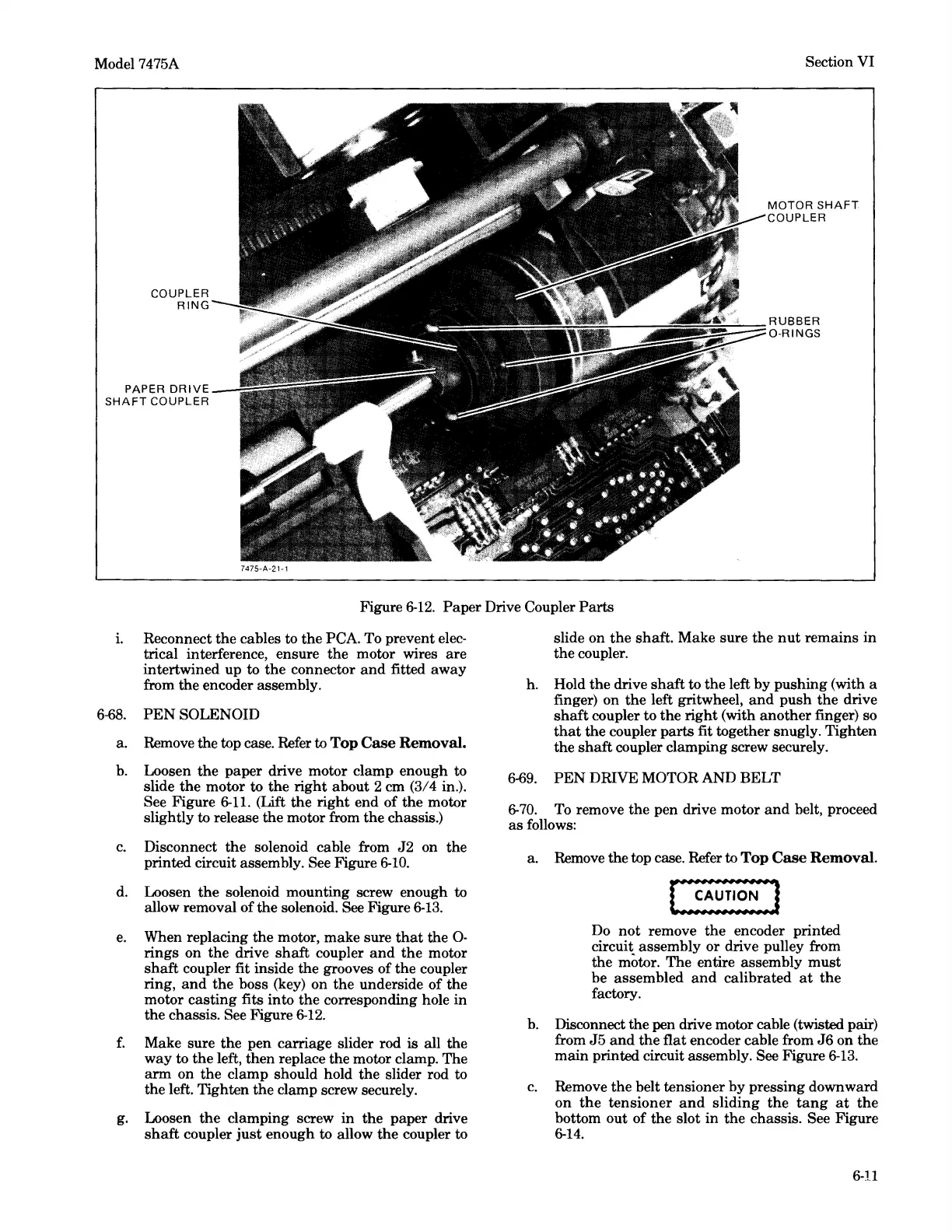

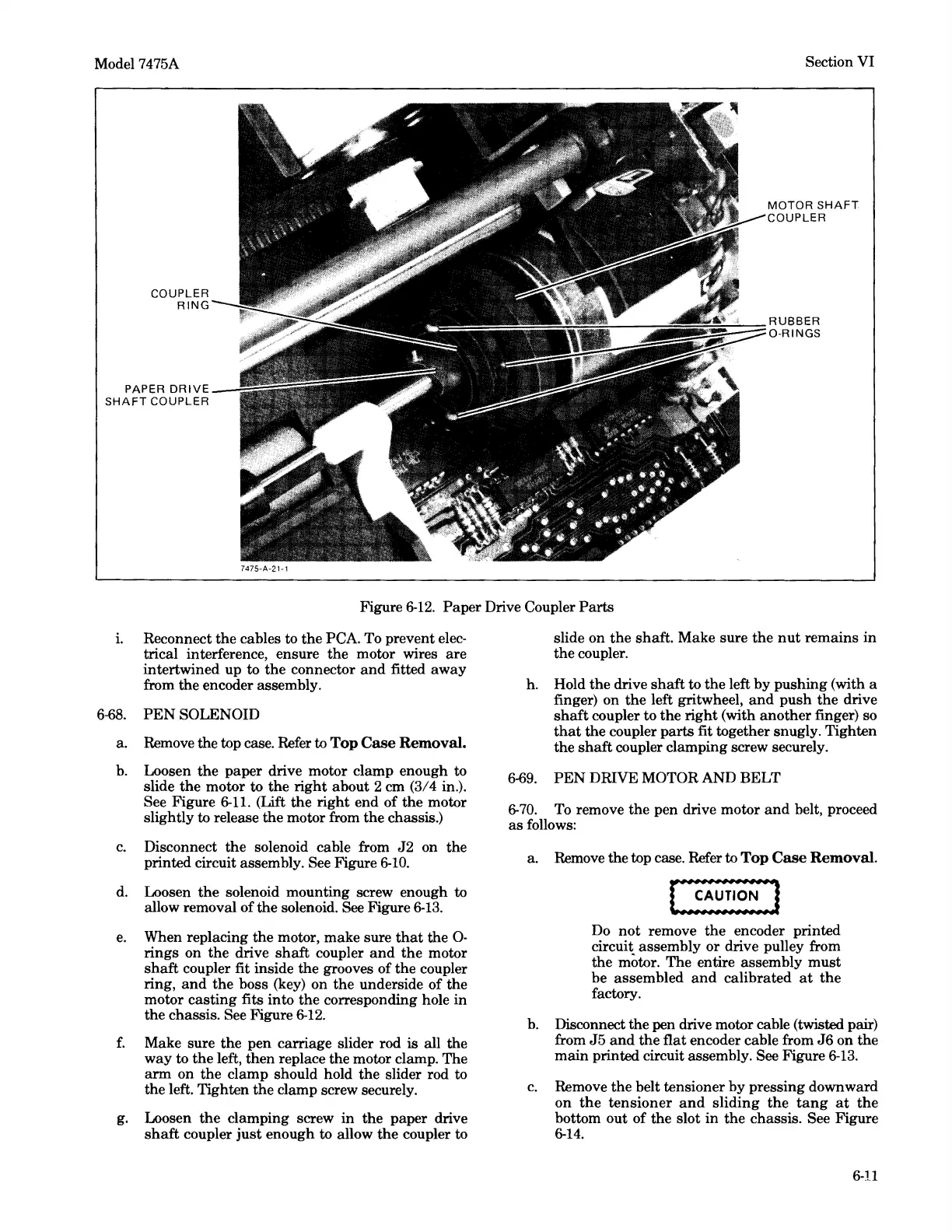

COUPLER

RING

PAPER

DRIVE

SHAFT

COUPLER

7475-A-21-1

Section VI

MOTOR

SHAFT

COUPLER

RUBBER

0-RINGS

Figure

6-12.

Paper

Drive Coupler

Parts

i. Reconnect

the

cables to

the

PCA. To prevent elec-

trical interference, ensure the motor wires

are

intertwined up to

the

connector

and

fitted

away

from the encoder assembly.

6-68.

PEN

SOLENOID

a. Remove the top case. Refer to Top

Case

Removal.

b.

Loosen

the

paper

drive motor clamp enough to

slide

the

motor to

the

right

about 2 cm (3/4 in.).

See Figure

6-11.

(Lift

the

right

end

of

the

motor

slightly to release

the

motor from

the

chassis.)

c.

Disconnect

the

solenoid cable from

J2

on the

printed circuit assembly. See Figure

6-10.

d. Loosen

the

solenoid mounting screw enough to

allow removal of the solenoid. See Figure

6-13.

e.

When replacing the motor, make sure

that

the

0-

rings

on

the

drive

shaft

coupler

and

the

motor

shaft

coupler fit inside the grooves of the coupler

ring,

and

the

boss (key) on

the

underside

of

the

motor

casting

fits into the corresponding hole in

the chassis. See Figure

6-12.

f.

Make sure

the

pen

carriage slider rod

is

all the

way

to

the

left, then replace the motor clamp. The

arm

on the clamp should hold the slider rod to

the left. Tighten

the

clamp screw securely.

g. Loosen

the

clamping screw

in

the

paper drive

shaft

coupler

just

enough to allow

the

coupler to

slide on

the

shaft.

Make sure

the

nut

remains

in

the coupler.

h. Hold

the

drive

shaft

to

the

left

by

pushing (with a

finger) on

the

left gritwheel,

and

push

the

drive

shaft

coupler to

the

right

(with

another

finger) so

that

the coupler

parts

fit together snugly. Tighten

the

shaft

coupler clamping screw securely.

6-69.

PEN

DRIVE MOTOR AND BELT

6-

70.

To remove

the

pen drive motor

and

belt, proceed

as

follows:

a. Remove the top case. Refer to Top

Case

Removal.

Do

not

remove

the

encoder printed

circuit assembly

or

drive pulley from

the motor. The entire assembly

must

be assembled

and

calibrated

at

the

factory.

b.

Disconnect the pen drive motor cable (twisted pair)

from

J5

and

the flat encoder cable from

J6

on

the

main

printed circuit assembly. See Figure

6-13.

c.

Remove

the

belt tensioner

by

pressing downward

on

the

tensioner

and

sliding

the

tang

at

the

bottom

out

of

the slot

in

the

chassis. See Figure

6-14.

6-U

Loading...

Loading...