Chapter 6 Function Introduction Shenzhen Hpmont Technology Co., Ltd

―72― HD5L Series Controller User Manual

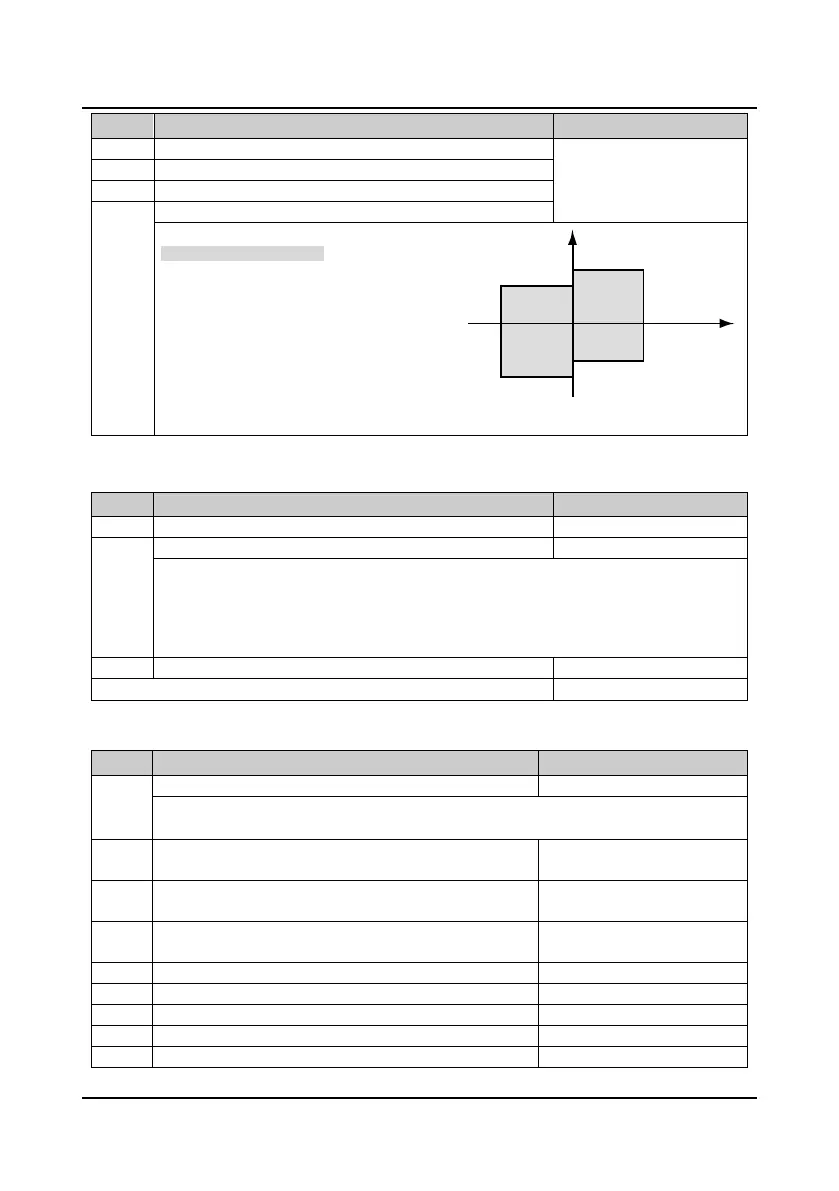

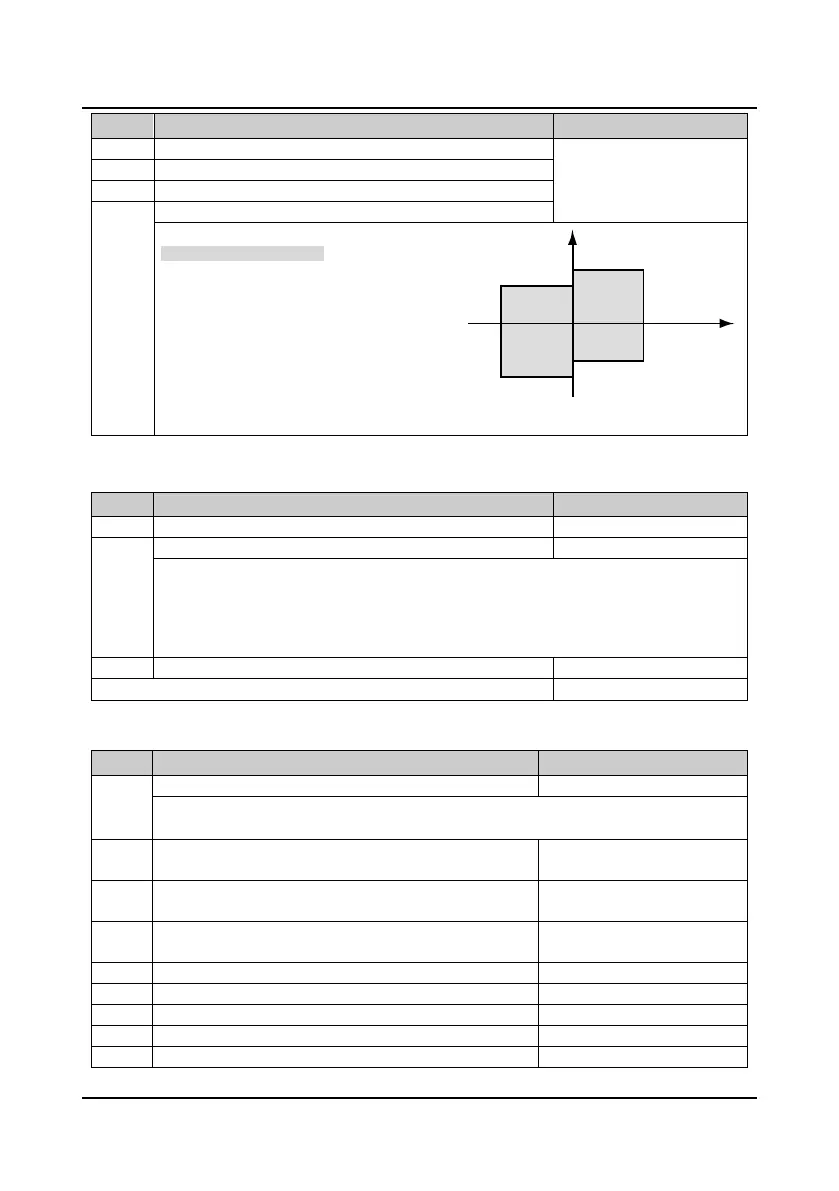

Code Name Description Range

factory setting

F08.09 UP electrical torque limitation 0.0

200.0 (F07.02)

180.0%

DN electrical torque limitation

F08.11 UP regenerative torque limitation

DN regenerative torque limitation

F08.09-F08.12 are the relative percentage of

motor rated current (F07.02).

As the right figure:

• The bigger torque output, the bigger curren

toutput.

• If the torque is too big, over-current is easy

to occur.

• If the torque is too small, the run speed and

the Acc/Dec speed may deviate from the

setting value.

6.2.10 Group F09 Current-loop Parameters

Code Name Description Range

factory setting

F09.00 Current-loop KP 1

4000

500

F09.00 and F09.01 are the PI regulator parameter of current ring (ACR).

• Increasing F09.00 or F09.01 can fasten the system dynamic response to the output torque, while

decreasing F09.00 or F09.01 can build up system stability.

• Too big F09.00 or F09.01 makes the system apt to oscillate, while too small F09.00 or F09.01

affects the system torque output.

Current-loop output filter time

F09.03

F09.07 Reserved

6.2.11 Group F10 Synchronous Motor Parameters

Code Name Description Range

factory setting

0: IPM

1: SPM

F10.01

Synchronous motor rated power

0.2

400.0kW

【Depend on controller model】

F10.02

Synchronous motor rated voltage

0

Controller rated voltage

Depend on controller model

F10.03

Synchronous motor rated current

0.0

999.9A

【Depend on controller model】

F10.04 Synchronous motor rated frequency 1.00

100.00

19.20Hz

Synchronous motor rated rpm

F10.06 Synchronous motor stator resistance 0.000

9.999

0.000Ω

Synchronous motor quadrature axis inductance

F10.08 Synchronous motor direct axis inductance 0.0

999.9

0.0mH

Motor Rpm

Output torque

UpDown

F08.11

F08.09

F08.10

F08.12

Negative

Positive

Loading...

Loading...