- 26 -

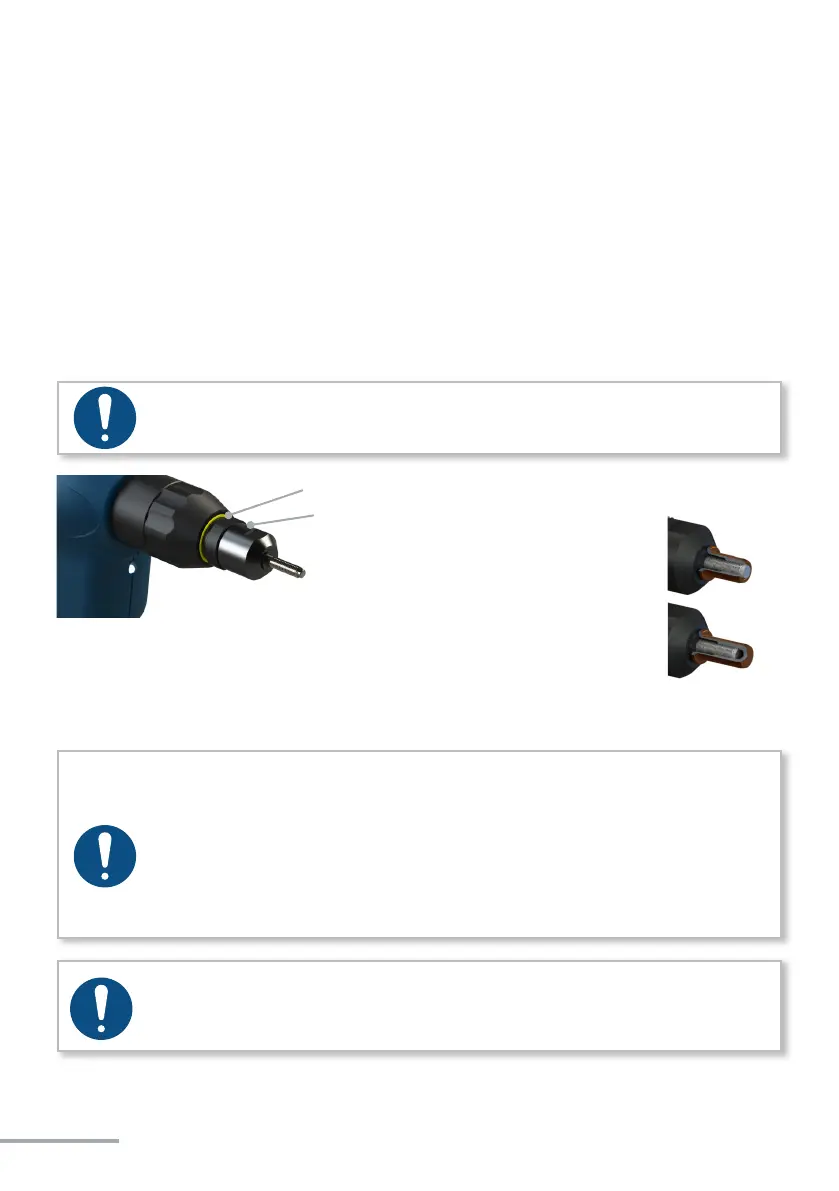

The nose piece must be adjusted to the blind rivet nuts to be processed.

Screw open blind rivet nuts by hand so that 1 - 2 threads sck out of the nut, see Figure

1. Lock the nose piece in this posion using the lock nut. With automac spinning on the

threaded mandrel should now be ush with the blind rivet nut.

With closed blind rivet nuts screw the nuts by hand as far as they will go, see Figure 2, and

then lock the nose piece using the lock nut. With automac spinning on the nut should

now be opmally spun on.

NOTE

These figures are intended as a guide and must proved in tests with the nuts used!

NOTE

Always place the riveting tool at a right angle (90°) to the work surface to be

riveted. An oblique placement leads to faulty riveting. Use only appropriate

threaded mandrels (sleeves) and nose pieces for the rivet nut. An incorrect

threaded mandrel (sleeve) and nose piece can lead to damage of the threaded

mandrel (sleeve), tool, screw thread and components. You can find the size of

the blind rivet nut in the rivet manufacturer’s information.

NOTE

Before using the tool for the first time it must be programmed, see chapter

4.4 on page 37.

Locking using lock nut

Addional fastening with screw

Fig. 1

Fig. 2

Loading...

Loading...