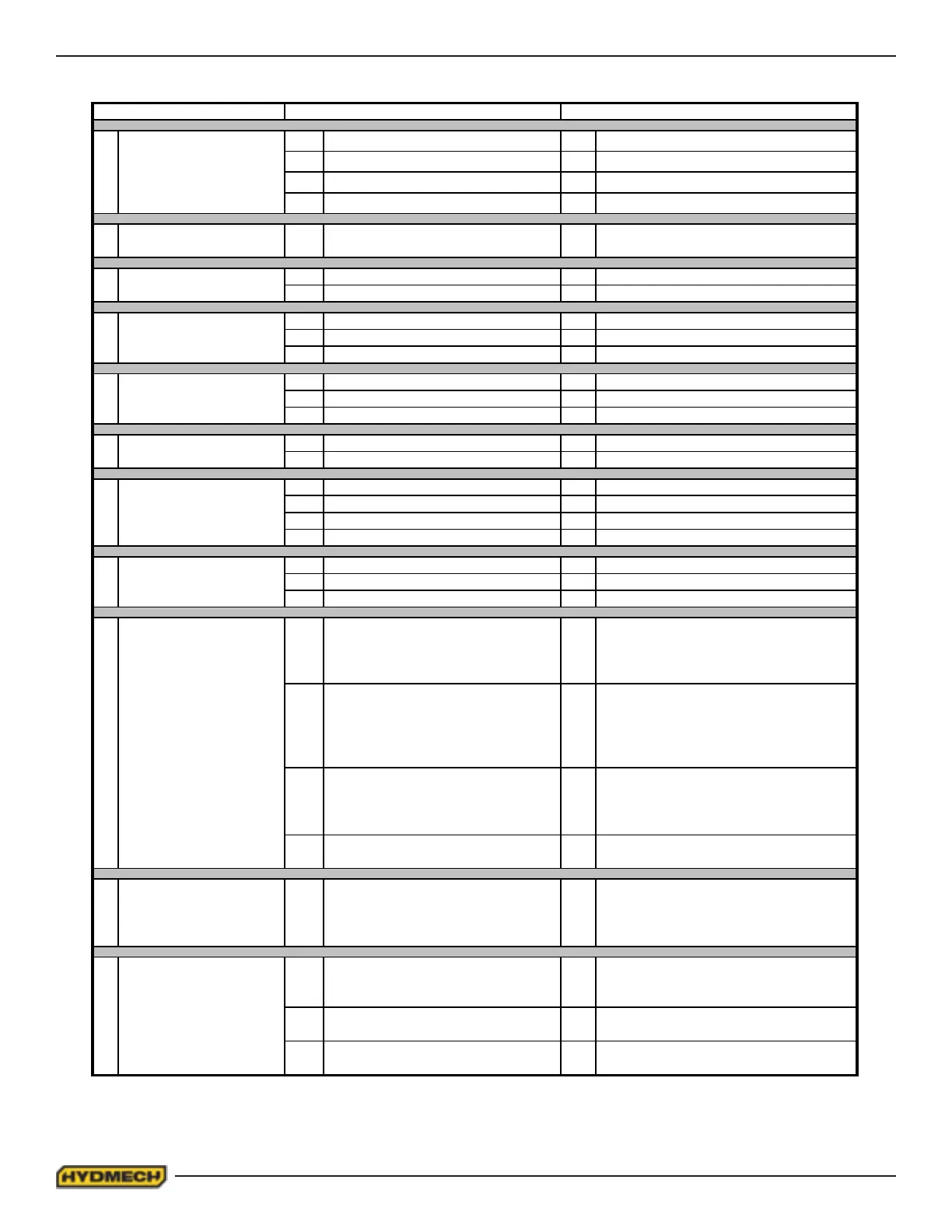

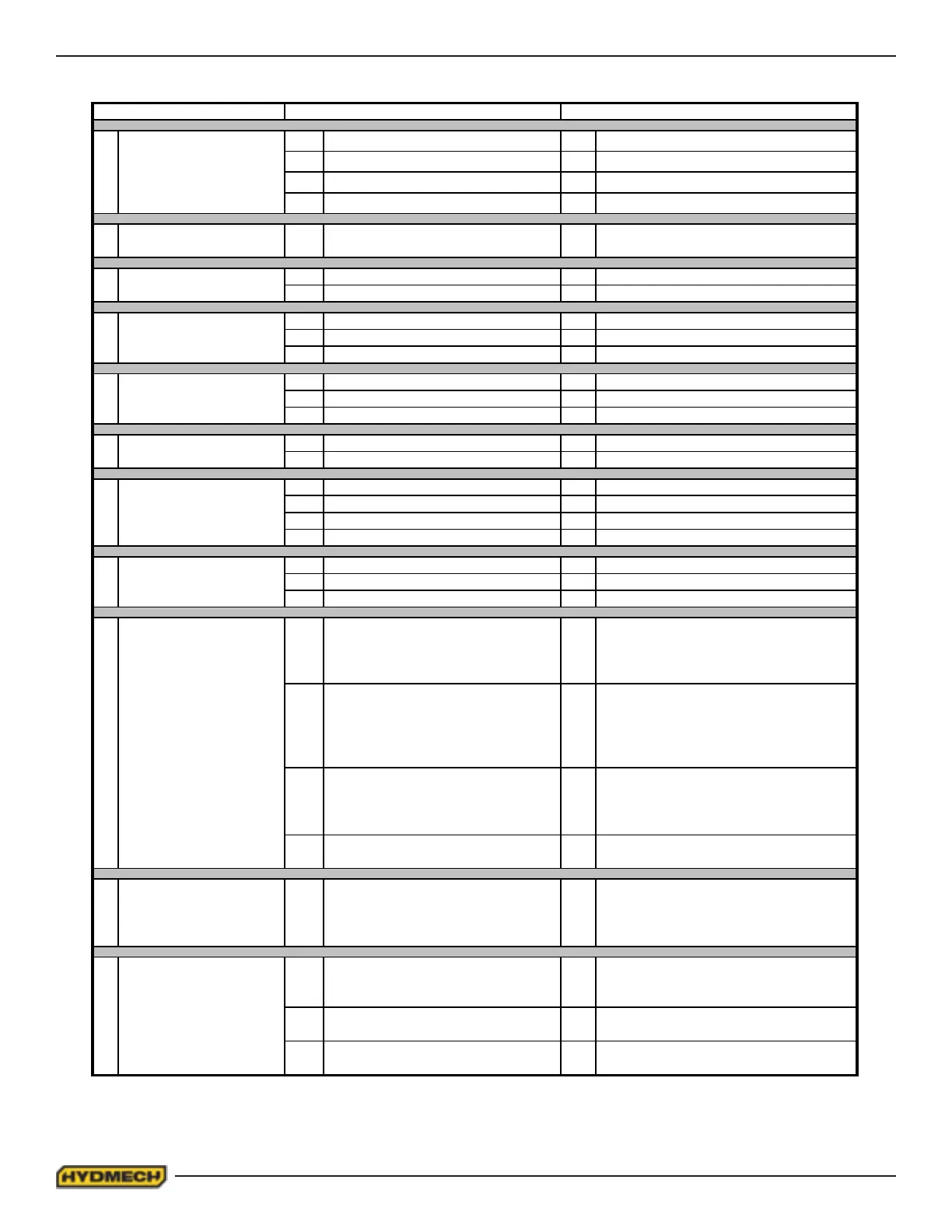

3.8

TROUBLESHOOTING

1a. Blade worn. 1a. Replace blade.

1b. Low blade tension. 1b. Tension blade.

1c. Blade guides. 1c. Check for worn guides.

1d. Excessive feed rate. 1d. Reduce.

2

Saw is cutting out of

square horizontally.

2 Stock not square in vises. 2 Adjust accordingly.

3a. Not enough blade tension. 3a. Reset blade tension.

3b. Improper tracking. 3b. Set tracking.

4a. Not enough blade tension. 4a. Tension blade.

4b. Excessive feed force. 4b. Reduce.

4c. Excessive feed rate. 4c. Reduce.

5a. Blade speed too fast. 5a. Reduce.

5b. Guide arms too far apart. 5b. Adjust accordingly.

5c. Not enough blade tension. 5c. Tension blade.

6a. Excessive blade tension. 6a. Reduce blade tension.

6b. Excessive feed rate. 6b. Reduce.

7a. Blade pitch too fine. 7a. Select coarser pitch.

7b. Blade brush not cleaning. 7b. Adjust or replace blade brush.

7c. Excessive feed rate. 7c. Reduce.

7d. Excessive feed force. 7d. Reduce.

8a. No coolant. 8a. Add coolant.

8b. Coolant line blocked. 8b. Blow out coolant line.

8c. Coolant pump inoperable. 8c. Check, replace if faulty.

9a. Safety relay is not energized 9a.

1.Ensure all Emergency Stop push

buttons are released.

2.Ensure Door interlock switches are

not activated.

Close Drive & Idler doors

9b. Motor overload has tripped. 9b.

Depress each of the over-load buttons

located in the electrical box. Depressing

one button at a time and trying to start the

saw will indicate which motor was

overloaded.

9c. Control circuit fuse has blown. 9c.

Replace the fuse in the control panel.

Random blowouts may occur but a quickly

repeated blowout points to an internal

wiring fault.

9d.

Vise or head selector switch not in the

center (neutral) position.

9d.

Turn all switches to the center (neutral)

position.

10

Saw starts but will not run

after Start button has been

released.

10

On machines so equipped, the

out-of-stock or blade breakage

limit switch has been tripped.

10

Reload with stock or reset the blade. Hold

the hydraulic start button and release the

blade tension or open vises far enough to

deactivate the limit switch.

11a.

If blade wheels run clockwise, wrong

phase order in power connection to

saw.

11a.

Stop immediately; reverse any two of the

three phase connections.

11b.

If pump is noisy cause may be low

hydraulic oil level.

11b.

Stop immediately, add hydraulic oil. (See

"Hydraulic Maintenance")

11c. Pump-motor coupling has separated. 11c. Adjust accordingly.

Saw starts but no hydraulic

functions.

11

Saw will not start.9

4

SOLUTIONPROBLEM PROBABLE CAUSE

8 No coolant flow.

1

Saw is cutting out of

square vertically.

Blade comes off wheels.3

Blade stalls in cut.

5 Blade vibrates excessively.

6 Excessive blade breakage.

7 Tooth strippage.

Loading...

Loading...