Page 77

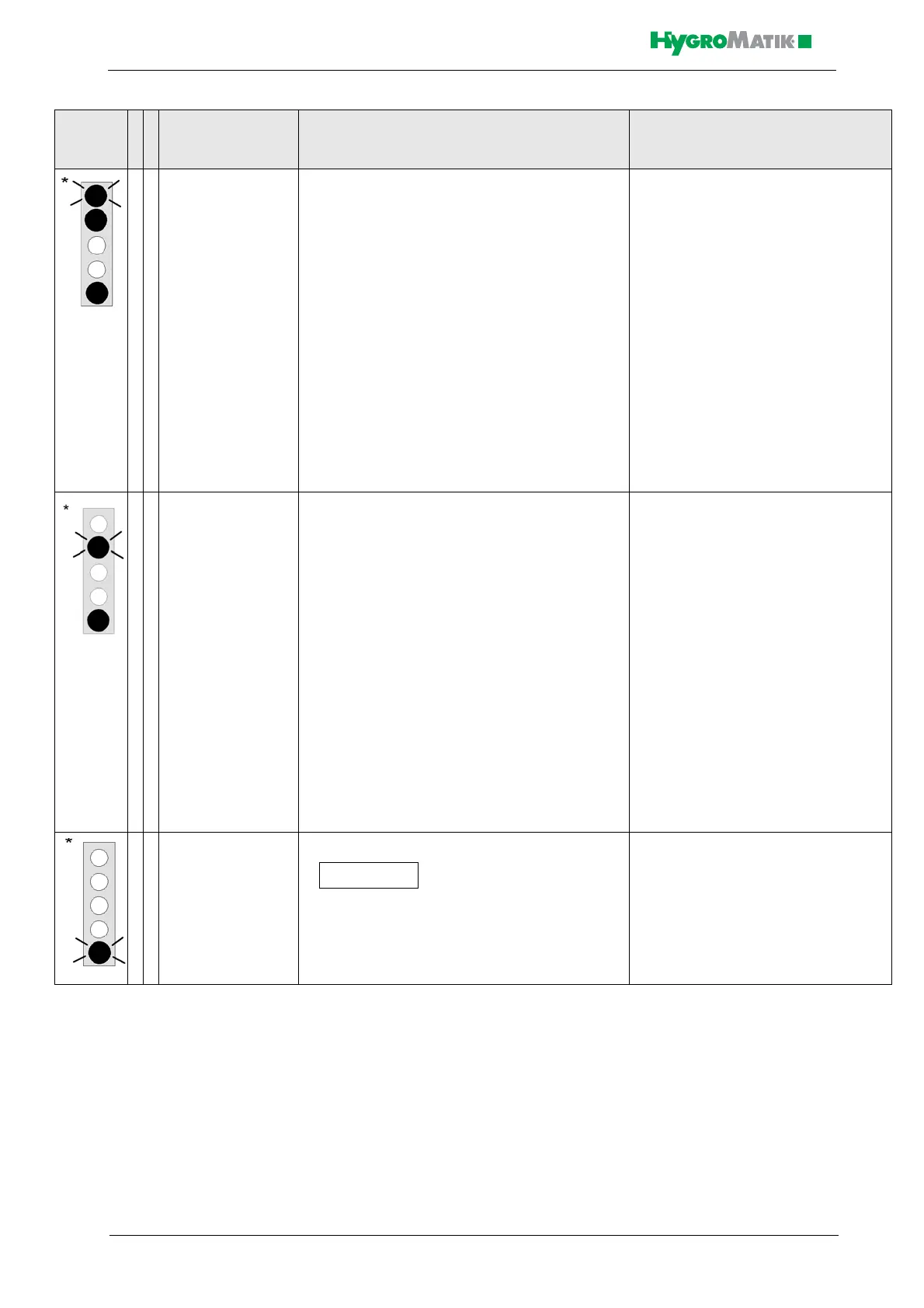

X

Fault steam-down

• Heater element is defective. • Measure resistance of the heater

element, replace heater element if

needed. Heater element resistance

at 4.5 kW: ca. 36 Ohm and at 6.75

kW: 24 Ohm

Unit shuts off auto-

matically.

• Phase failure. (External breaker has been

tripped or is defective.)

• Replace circuit breaker and identify

cause.

Fault steam-down • Heater element is not being supplied with

current.

• Check cable connections. Measure

voltage.

Unit shuts off auto-

matically.

• Main contactor is not switching correctly. • Check main contactor, replace if

needed..

• PCB does not activate main contactor. • Measure voltage at PCB terminals

12, 13, 14 against N. Replace PCB

if necessary.

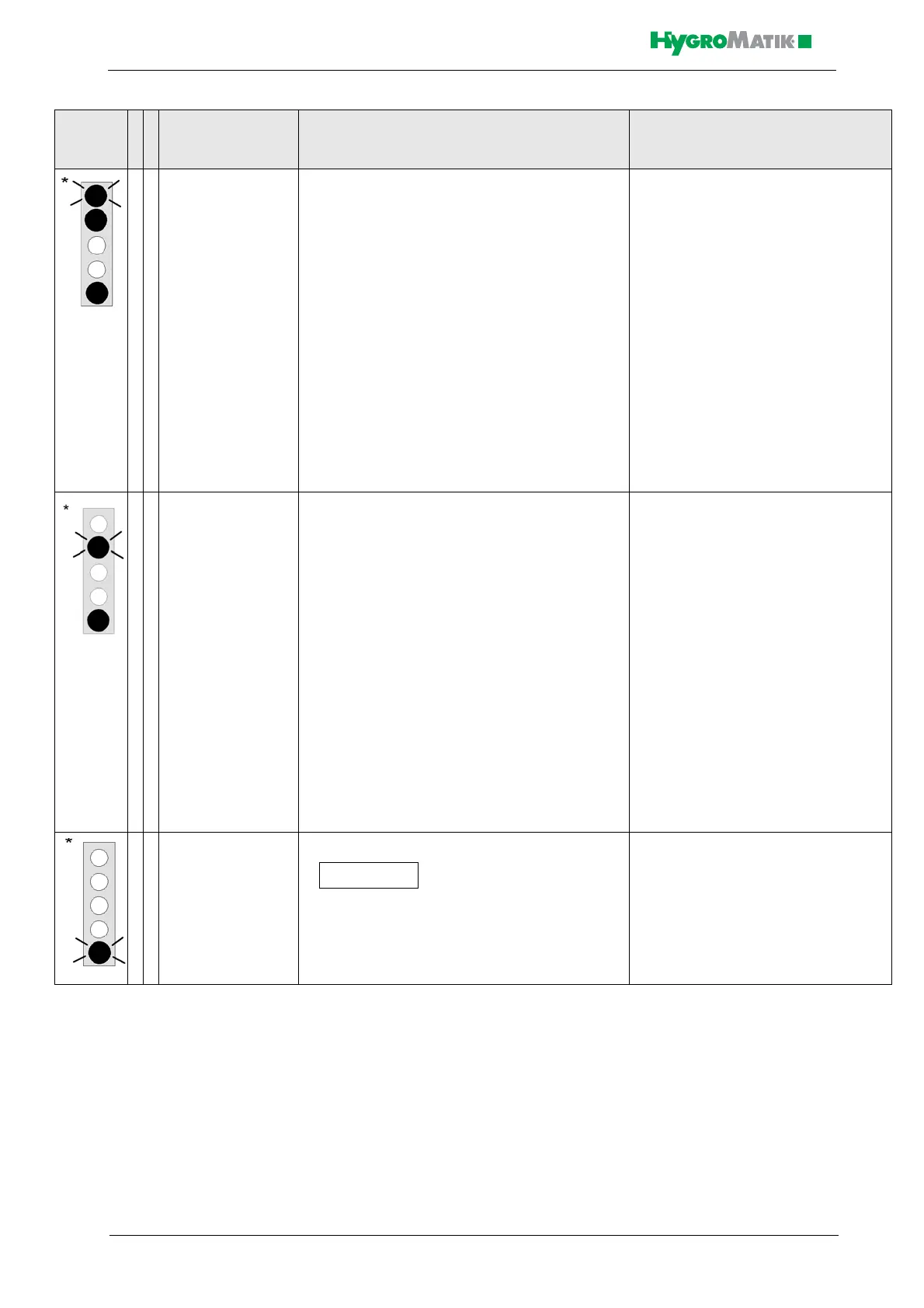

X

Message Cylinder

Full

• Nominal current or nominal output not

reached although cylinder filled up to

maximum-limitations electrode. Water imput

is interrupted. Possible causes:

• Continous steam production and

increasing water conductivity can

cause the control lamp to switch off

automatically after a period of

operation time. nominal output is

reached automatically.

Feed a cable through current

transducer ring.

- Water conductivity too low.

- Cold start.

- Re-start following full blow-down.

- Changing water conductivity.

• Check water values and/or contact

HygroMatik.

- Electrodes worn out • Replace electrodes.

• Unit requires maintenance. • See Service section in this manual.

• No electrode supply cable fed through current

transducer ring.

•

XX

Service • The maintenance interval has expired.

The status of the four upper LED is depend-

ing on the momentary operation mode of the

humidifier.

• Service or check steam humidifier.

Reset the maintenance interval at

Parameter P3 “Reset Maintenance

Interval”. With Parameter P2, the

maintenance interval can be ad-

justed to the feed water quality.

LED Dis-

play

HL ***

Hy,C***

Message / Mal-

function Dis-

played*

Probable Cause Resolution

Loading...

Loading...