12 43576

51324 76

4321

1

A

432

A

B

C

D

B

C

D

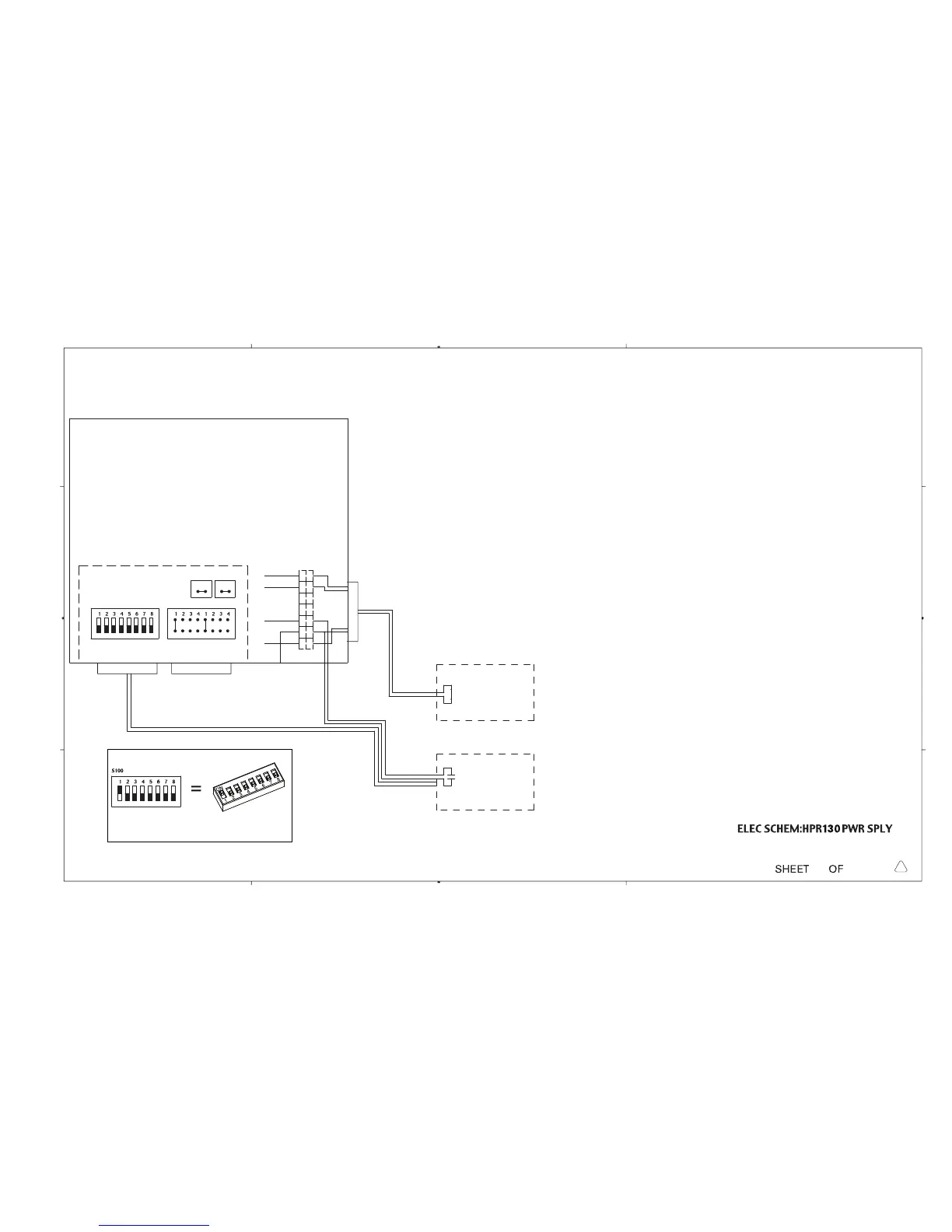

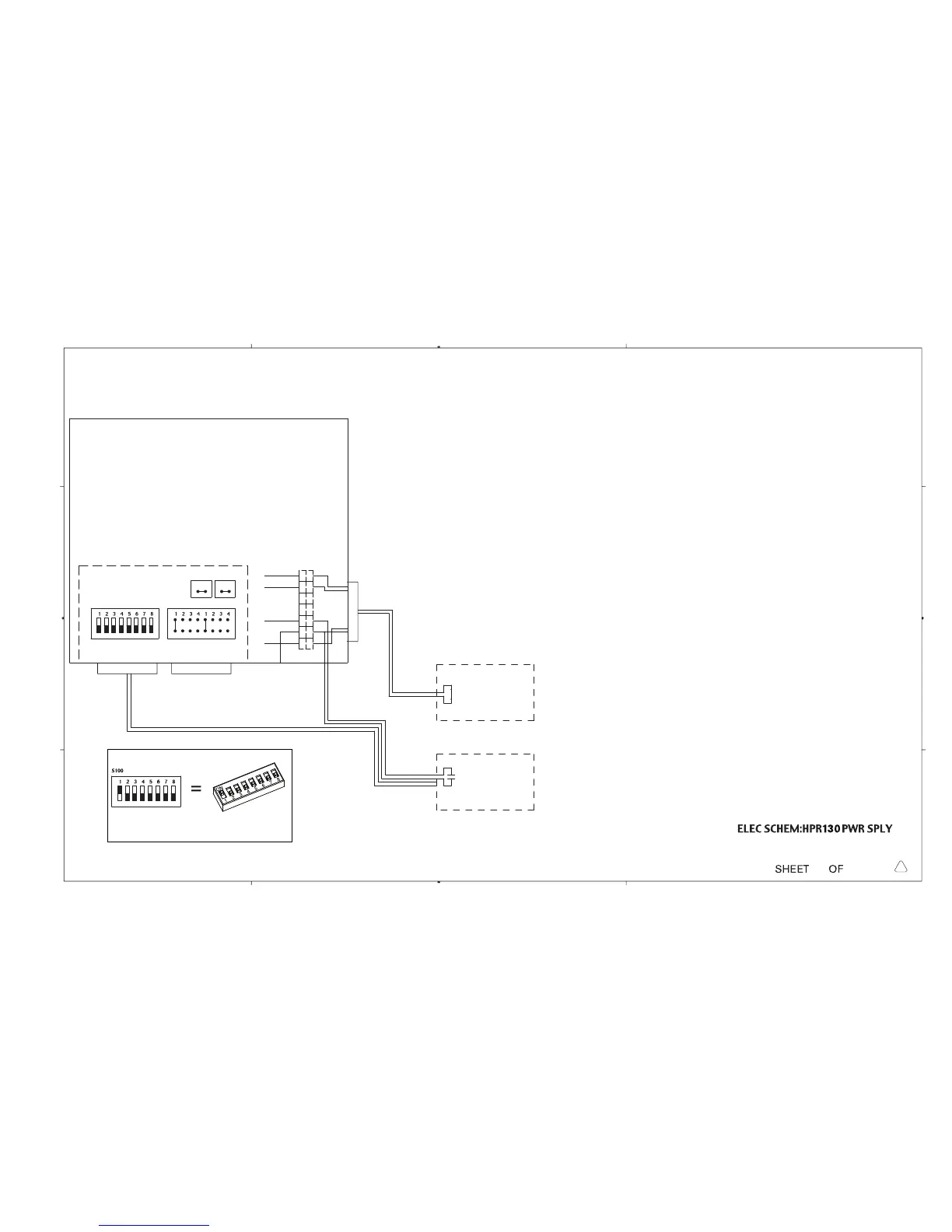

Interface

CNC

(Customer Supplied)

041909

CONTROL BOARD

S100

J303

J300A J300B

Serial ID

Dipswitch Jumper Block

Machine Motion

Machine Interface I/O Cable

7

RED/BLK

RED

WHT

RED

Gas Console

078170

PS/Gas Power Cable

Customer Supplied

Remote On/Off

J106

2121

J107

Optional Remote On/Off

TB2

WHT

RED

RED/BLK

RED

6

2

1

1X1

Notes:

1) For single system installation set Serial ID (S100), Machine

Motion (J303), J106 & J107 as shown.

Relocate the white wire on TB2 from position #3 to position

#2. Connect customer supplied Remote On/Off cable in series

with the power supply and the gas console power switch.

Connect one terminal of the Remote On/Off cable to position

#2 on TB2 and the other terminal to position #3.

Refer to page 3 of the wiring diagram

Depress the Gas Console Power switch to the closed position (on position).

2) For a multi-system installation set up as described above, set jumpers as shown on the

multi-system interface page

3) The CNC will need a dedicated I/O for each system using the Remote On/Off feature

(contact should be rated for min. 24Vac, 0.5 Amp)

HPR PAC

Dry Cutting System

17

16

013348

K

Dipswitch setting example:

Switch 1 is in the ON position.

Switches 2-8 are in the OFF position.

Loading...

Loading...