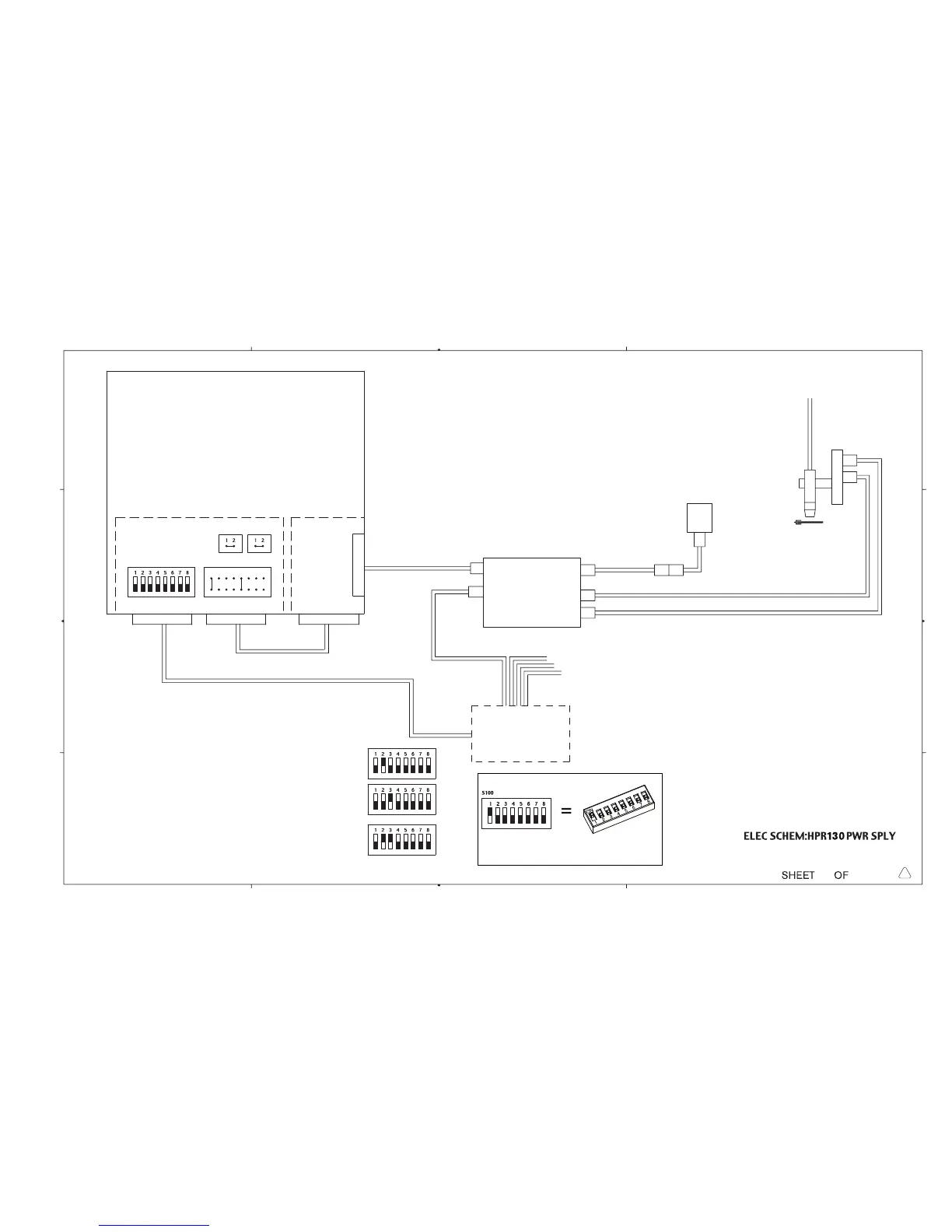

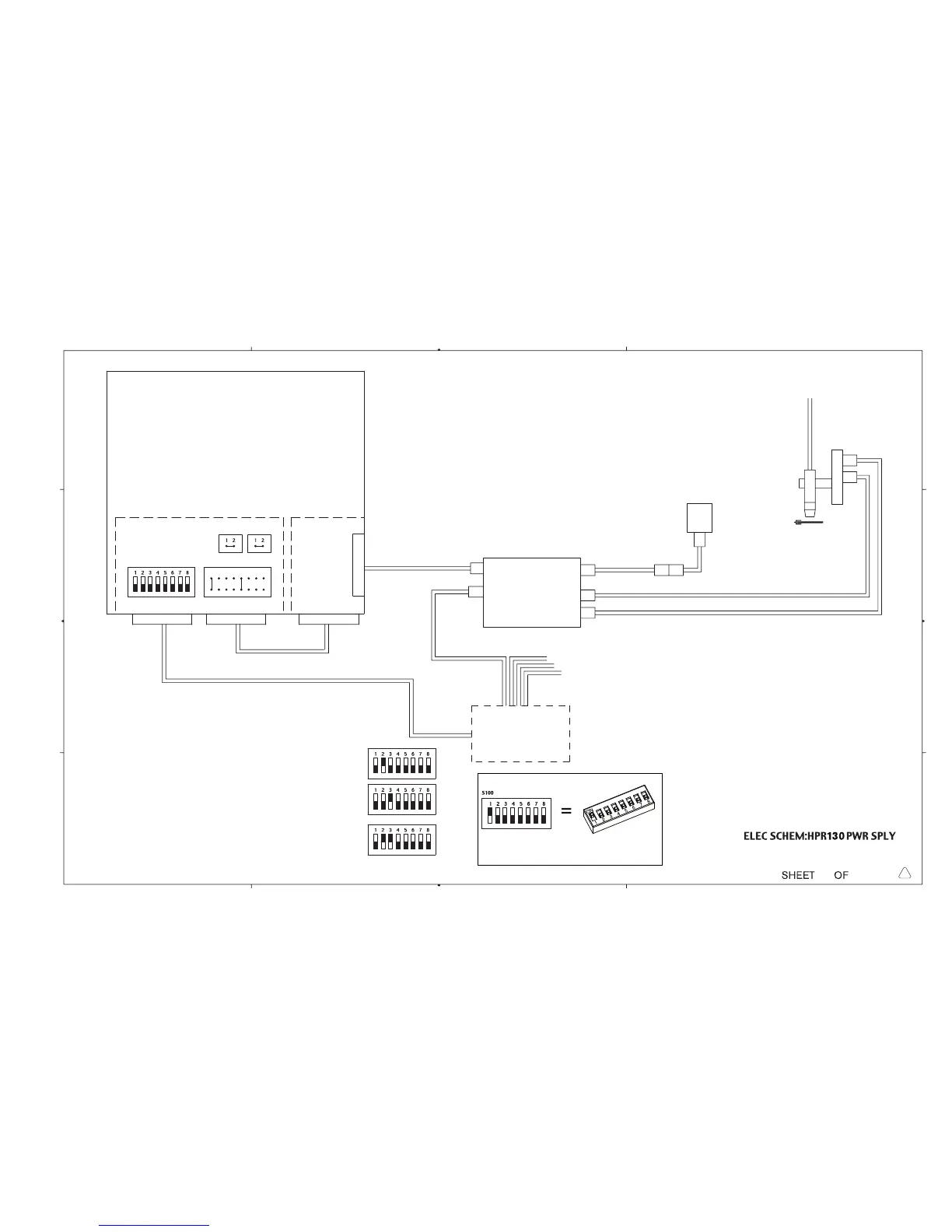

Dipswitch setting example:

Switch 1 is in the ON position.

Switches 2-8 are in the OFF position.

7-23

6

4321

1

A

432

A

B

C

D

B

C

D

Interface

CNC

(Customer Supplied)

041909

CONTROL BOARD

S100

12

J303

34 3214

J300A J300B

Machine Interface

I/O Cable

Torch 220163

Workpiece

Command I/O Cable

(Optional Unit)

THC

Command

Machine I/O Cable

Pendant Ext. Cable

(Optional Unit)

Operator

Pendant

Lifter

Tor ch

(Optional Unit)

QD Assy

220162

THC Motor Drive Cable

Command I/O Cable

J2B

J2A

PLASMA INTERFACE

BOARD

041842

Serial ID

Dipswitch

Jumper Block

Machine Motion

Machine Interface I/O Cable

Command I/O Cable-Second THC

Command I/O Cable-Third THC

Command I/O Cable-Fourth THC

Dipswitch

(2 systems)

Serial ID

S100

S100

Dipswitch

(3 systems)

Serial ID

S100

Dipswitch

(4 systems)

Serial ID

J106 J107

Optional Command THC Interface

Notes:

1) For a single system installation set Serial ID (S100),

Machine Motion (J303), J106 & J107 as shown

2) For a two system installation duplicate a second power supply and Command THC

as illustrated for a single system, set Serial ID as shown for the second system

3) For a three system installation set up as described above, set Serial ID as shown

for the third system

4) For a four system installation set up as described above, set Serial ID as shown

for the fourth system

5) All machine interface cables (Pwr. supply-CNC) used for serial communication between

Pwr. supply-CNC will have a common connection node with the CNC

6) The CNC will need a dedicated I/O port for each Command THC

HPR PAC

Dry Cutting System

See Command THC

Manual for Internal

Power Supply Wiring

17

17

013348

K

Loading...

Loading...