OperatiOn

4-16 HPR130XD Auto Gas – 806330 Revision 2

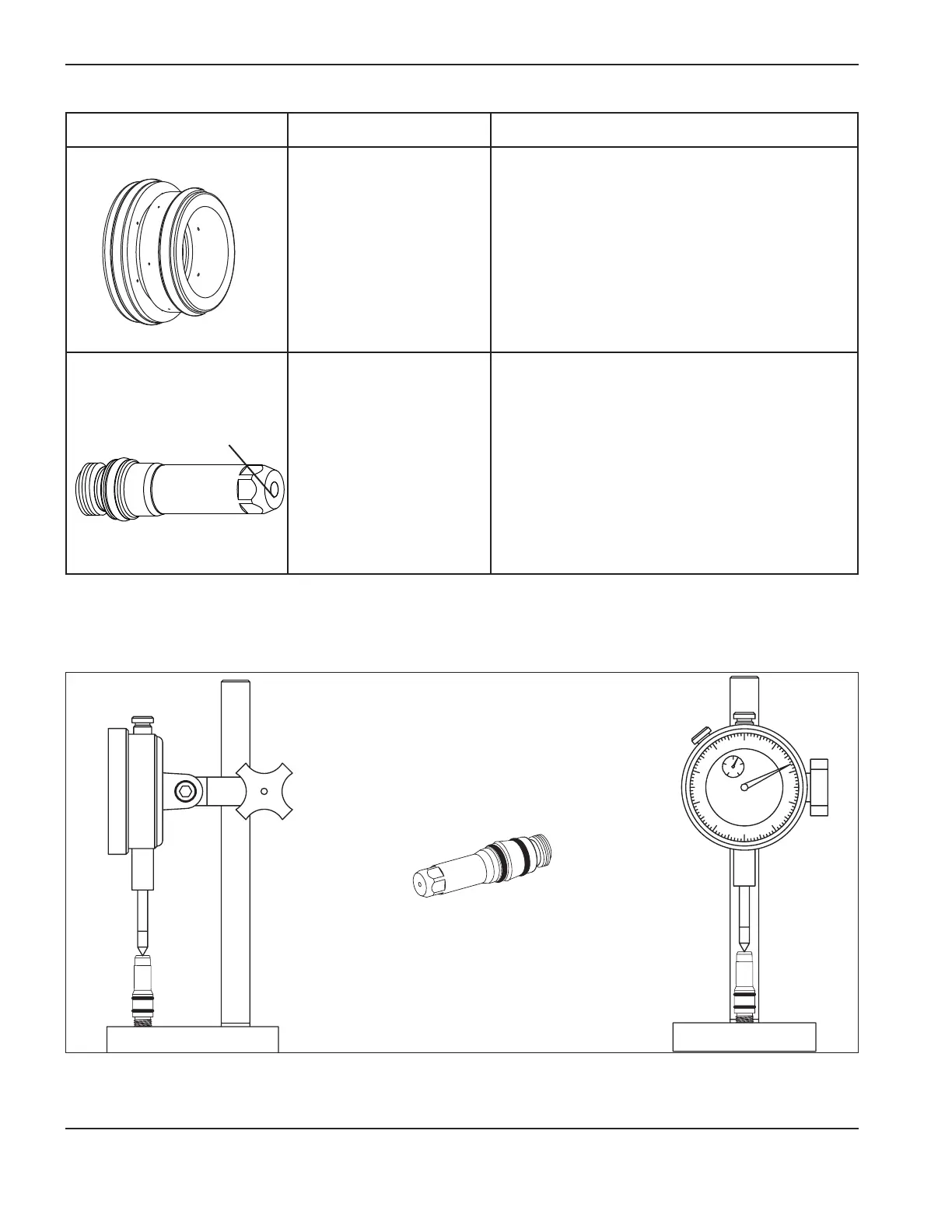

Inspect Look for Action

Swirl ring

General:

Chips or cracks

Blocked gas holes

Dirt or debris

O-rings:

Damage

Lubricant

Replace swirl ring

Replace swirl ring

Clean and check for damage; replace when damaged

Replace swirl ring

Apply a thin film of silicone lubricant if the o-rings

are dry

Electrode

Always replace the nozzle and

electrode as a set.

Center surface:

Emitter wear – a pit forms as

the emitter wears.

O-rings:

Damage

Lubricant

In general, replace the electrode when the pit depth is

1 mm (0.04 in.) or greater. For the 400 A mild steel

electrode and all SilverPlus electrodes, replace the

electrode when the pit depth is 1.5 mm (0.06 in.) or

greater. See Electrode pit depth gage below.

Replace electrode

Apply a thin film of silicone lubricant if the o-rings

are dry

Emitter

10

0

20

40

30

4

0

2

3

1

80

60

70

50

90

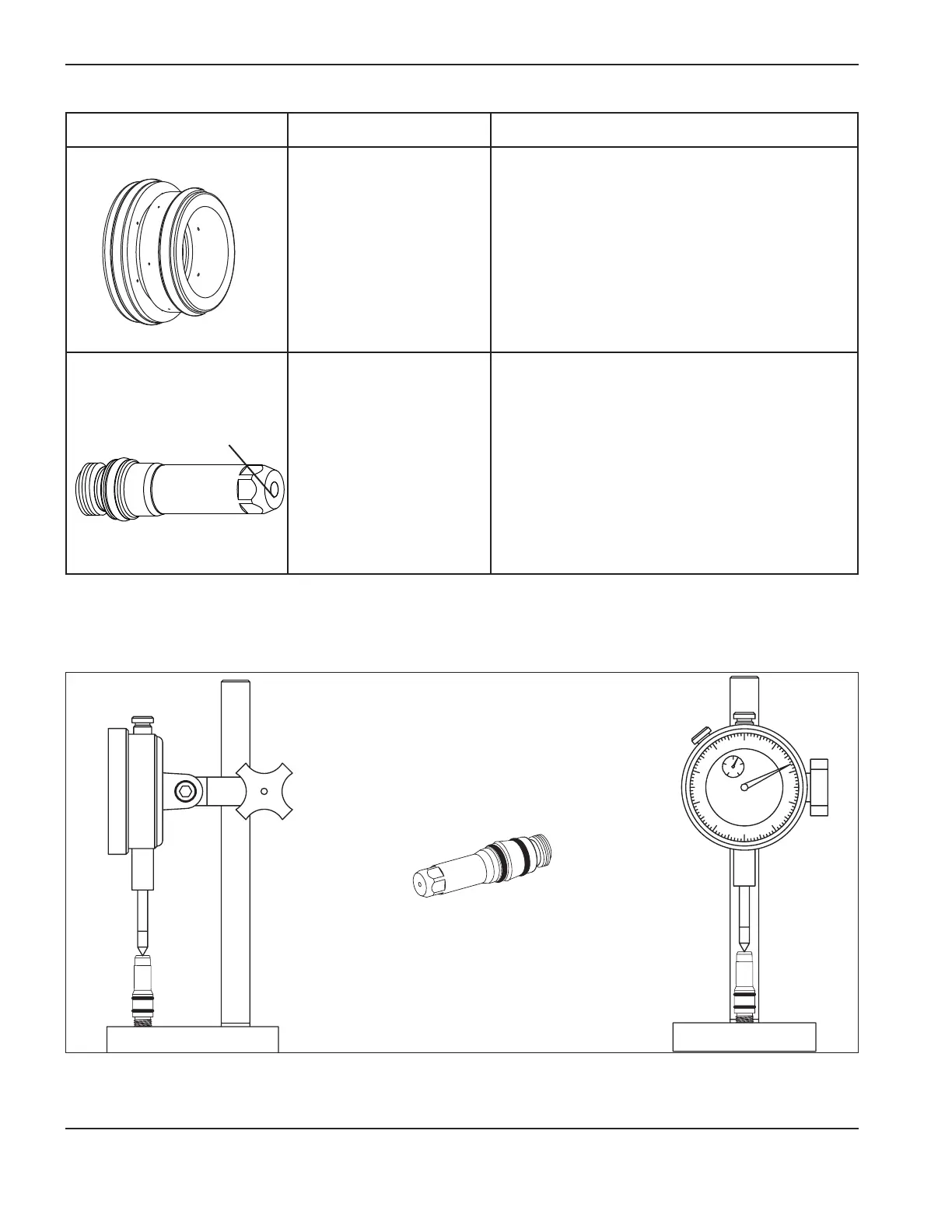

Electrode pit depth gage (004147)

Loading...

Loading...