InstallatIon

HPR130XD Auto Gas – 806330 3-43

Torch lifter requirement

The system requires a high-quality, motorized torch lifter with sufficient travel to cover all cutting thickness requirements.

The lifter must provide 203 mm (8 in.) of vertical travel. The unit should have the capability of maintaining a constant

speed of up to 5080 mm/min (200 ipm) with positive braking. A unit which drifts through the stop point is not

acceptable.

Hypernet

Hypernet is only used to connect certain Hypertherm components to each other. An HPRXD system can be connected

to the ArcGlide

®

torch height control, and an EDGE

®

Pro or MicroEDGE

®

Pro CNC using an ethernet hub and cable.

The Hypernet PCB provides communication between components and is the source for the arc voltage needed for the

torch height control. See the ArcGlide instruction manual (806450), the EDGE Pro instruction manual (806360) or the

MicroEDGE Pro CNC instruction manual (807290) for more information.

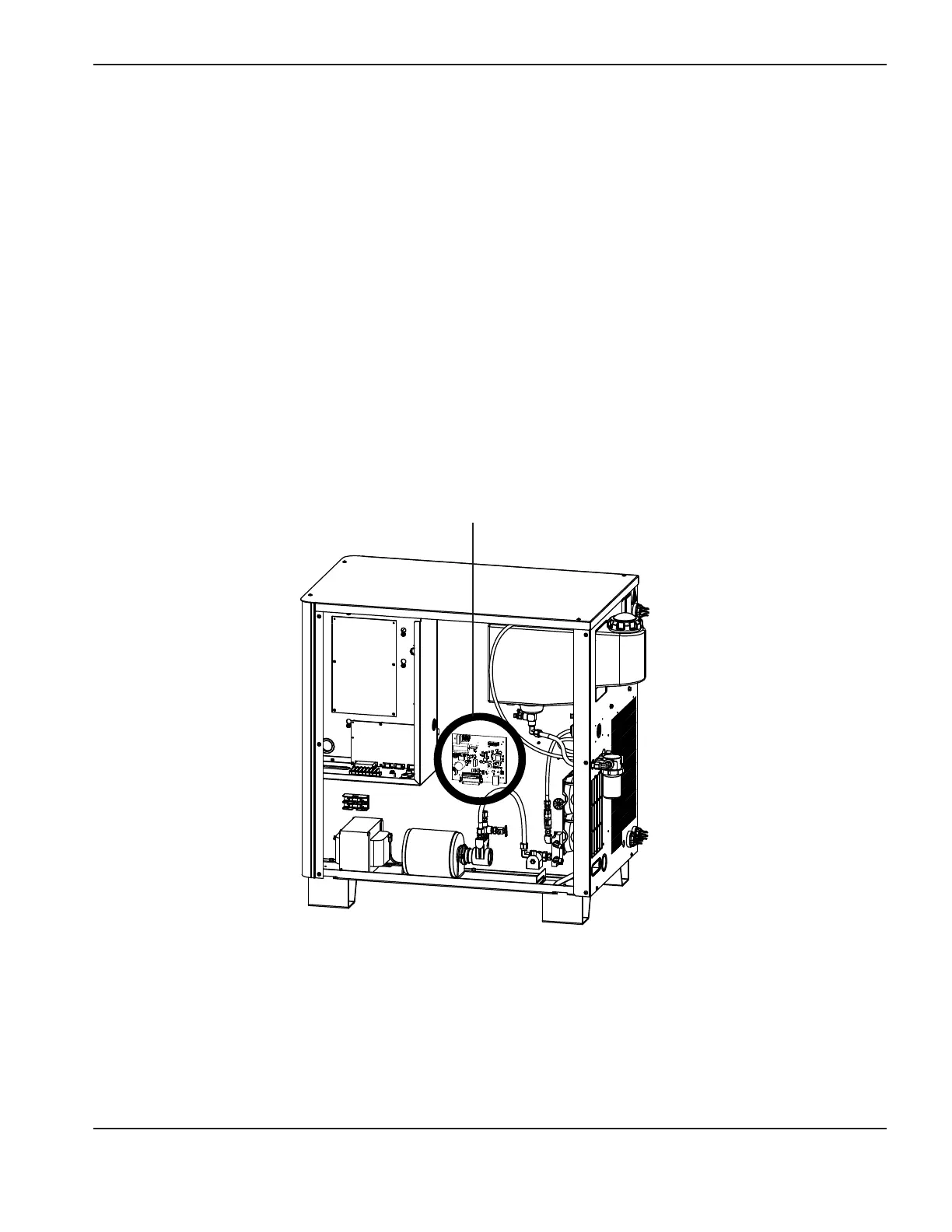

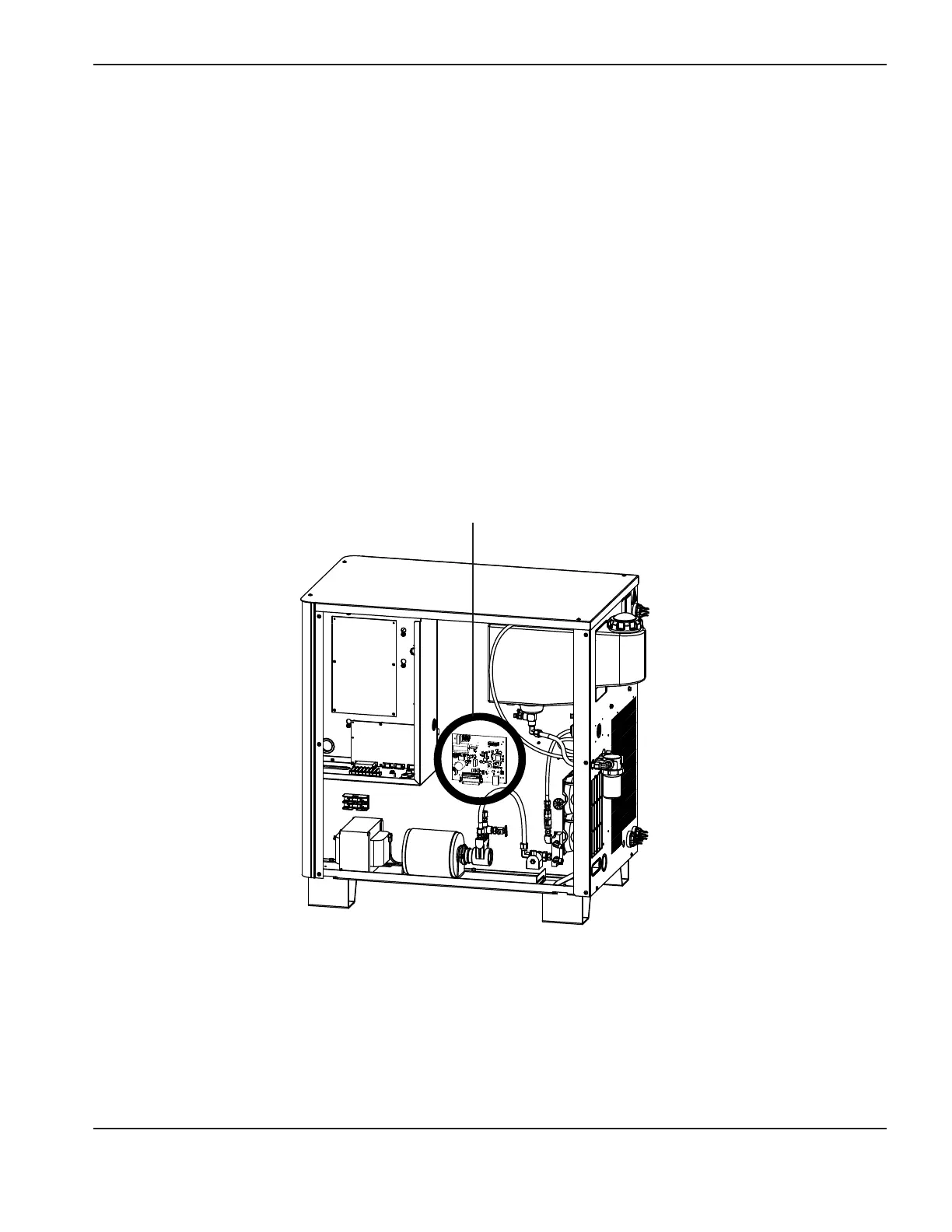

Location of the Hypernet PCB

Loading...

Loading...