OperatiOn

HPR130XD Auto Gas – 806330 Revision 2 4-45

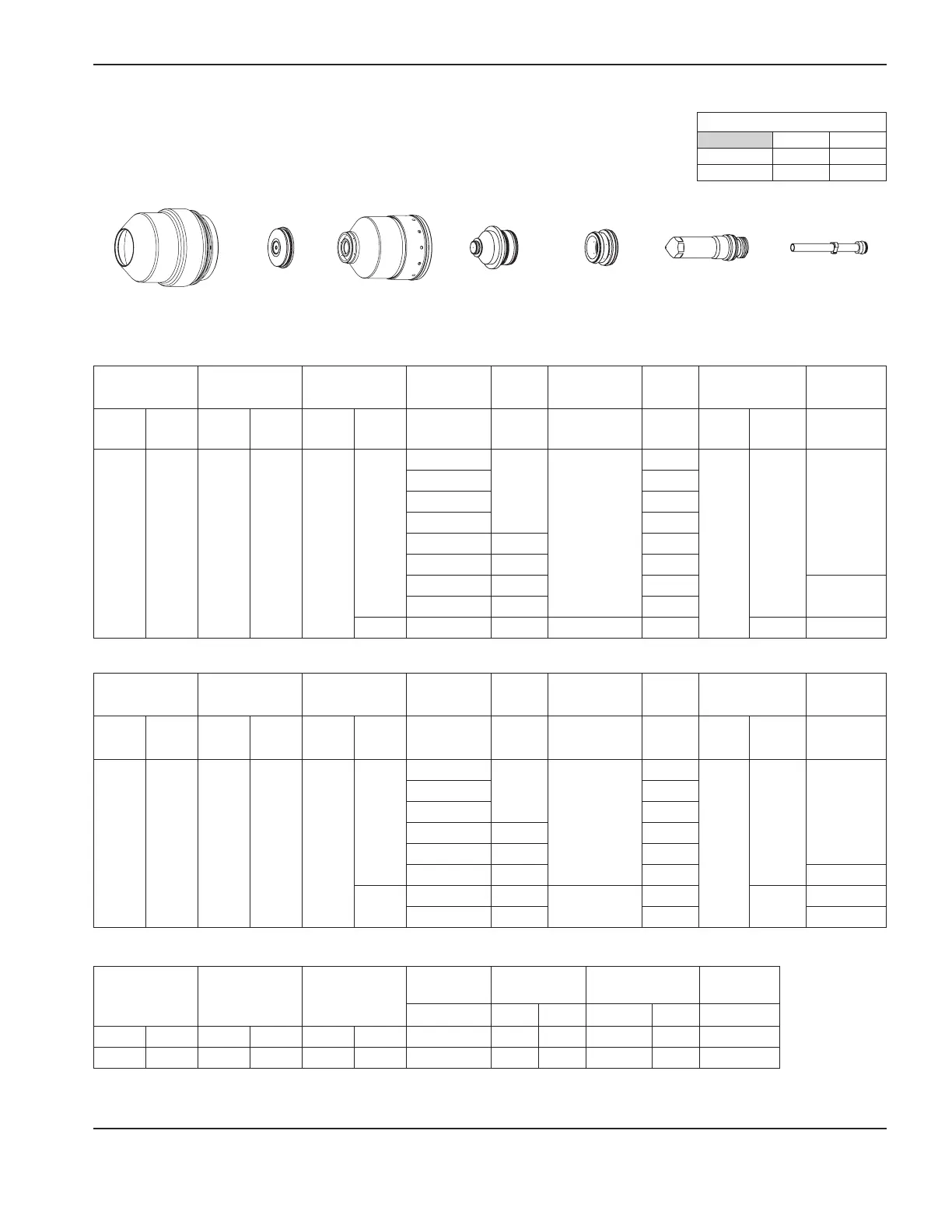

Stainless steel

F5 Plasma / N

2

Shield

45 A

Note: This process produces a shinier cut edge than the 45 A, N

2

/N

2

stainless steel process.

Metric

English

Select

Gases

Set

Preflow

Set

Cutflow

Material

Thickness

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

mm Volts mm mm/m mm Factor % Seconds

F5 N

2

35 18 62

49

0.8

99

2.5

6570

3.8

150

0.2

1 5740

1.2 4905

1.5 3890

2 101 3175

2.5 102 2510

3 103 2010

0.3

4 104 1435

11 6 110 2.0 845 190 0.5

Select

Gases

Set

Preflow

Set

Cutflow

Material

Thickness

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce

Height

Pierce Delay

Time

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

Plasma

gas

Shield

gas

inches Volts inches ipm inches Factor % Seconds

F5 N

2

35 18 62

49

0.036

99

0.10

240

0.15

150

0.2

0.048 190

0.060 150

0.075 100 130

0.105 102 90

0.135 104 65 0.3

11

3/16 108

0.08

45

190

0.4

1/4 110 30 0.5

Marking

Flow rates – lpm/scfh

F5 N

2

Preflow 0 / 0 43 / 91

Cutflow 8 / 17 65 / 138

Select

Gases

Set

Preflow

Set

Cutflow

Amperage

Torch-to-Work

Distance

Marking

Speed

Arc

Voltage

A mm inches mm/m ipm Volts

N

2

N

2

10 10 10 10 15 2.5 0.10 6350 250 85

Ar N

2

90 10 90 10 12 2.5 0.10 2540 100 65

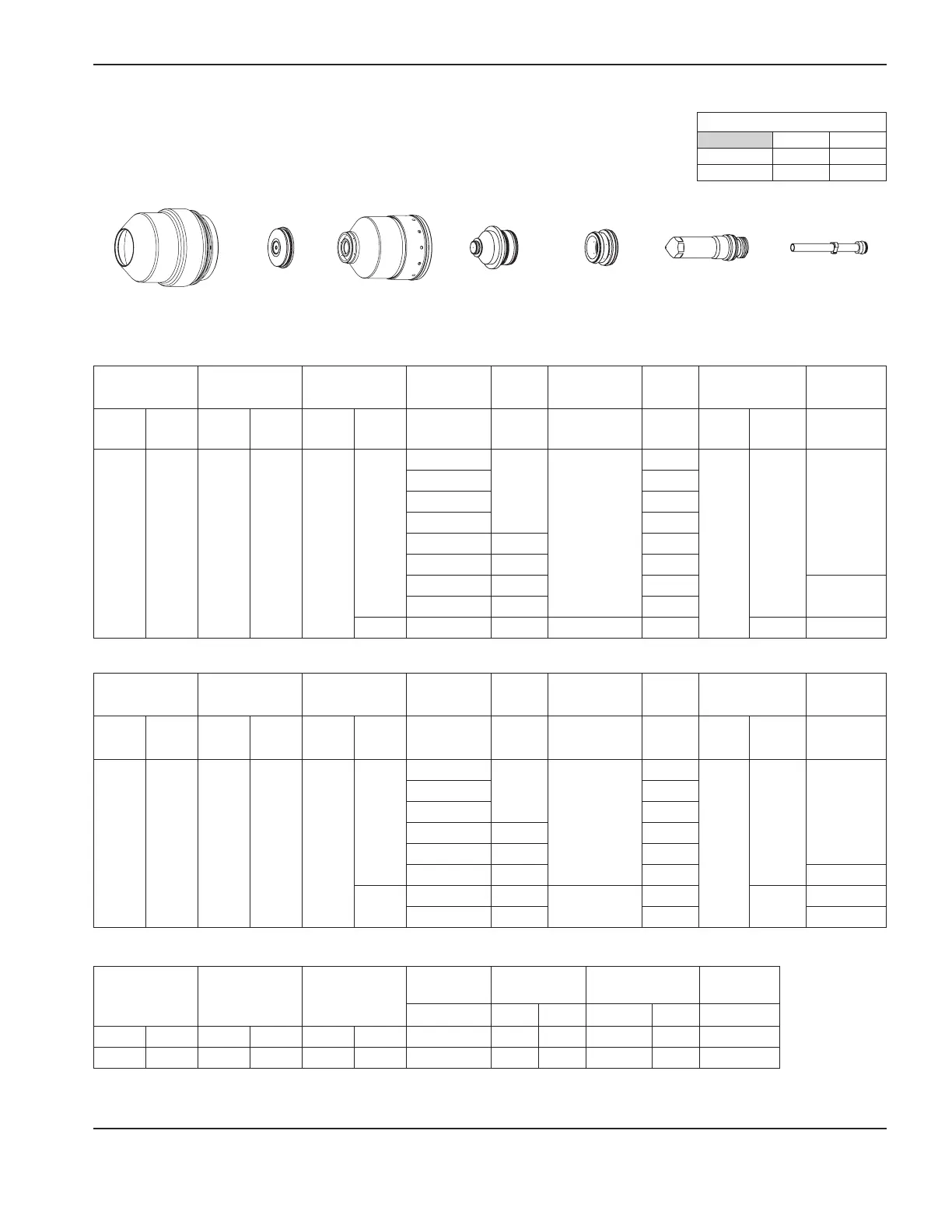

220202220747 220308220755 220180220201 220340

Loading...

Loading...