32

Troubleshooting (Cont’d.)

10

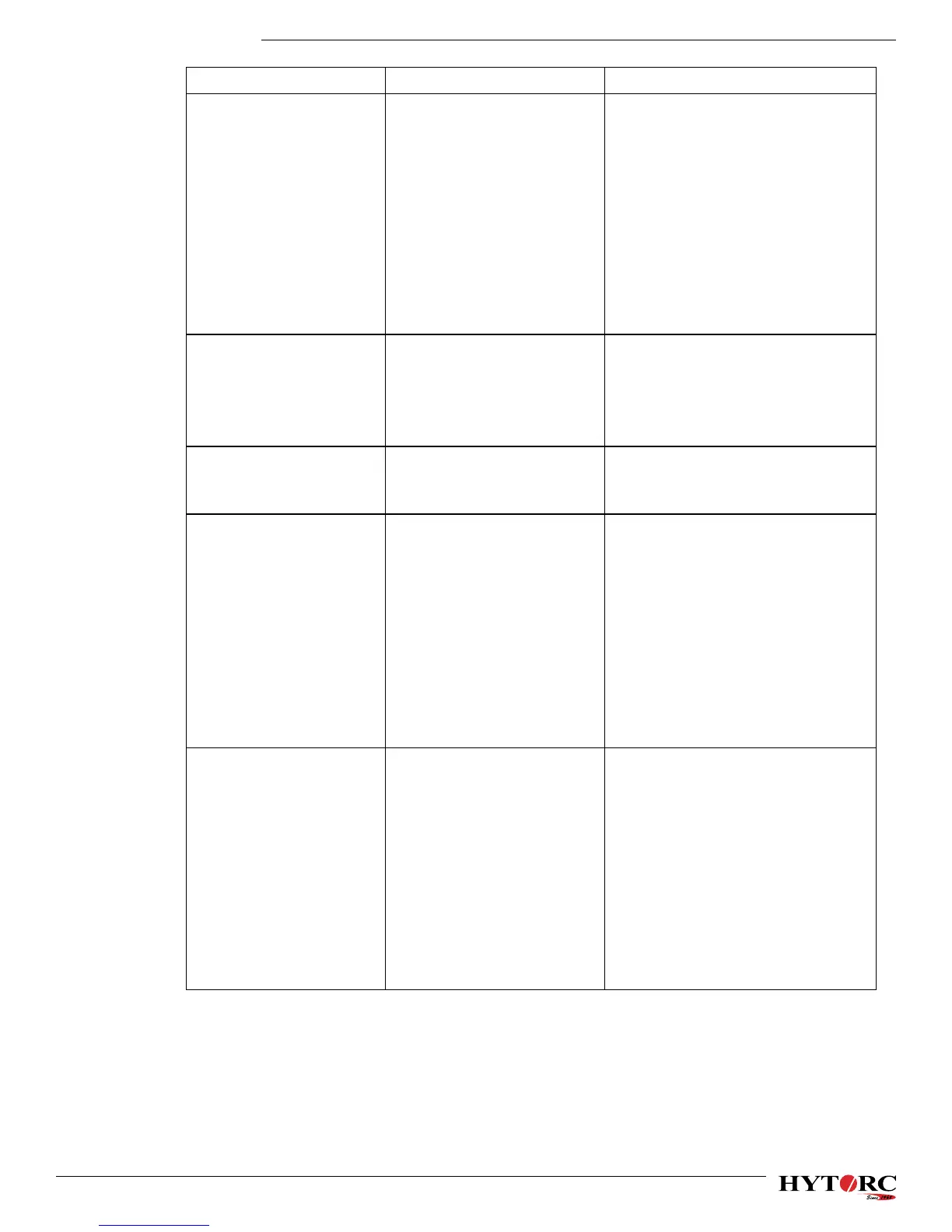

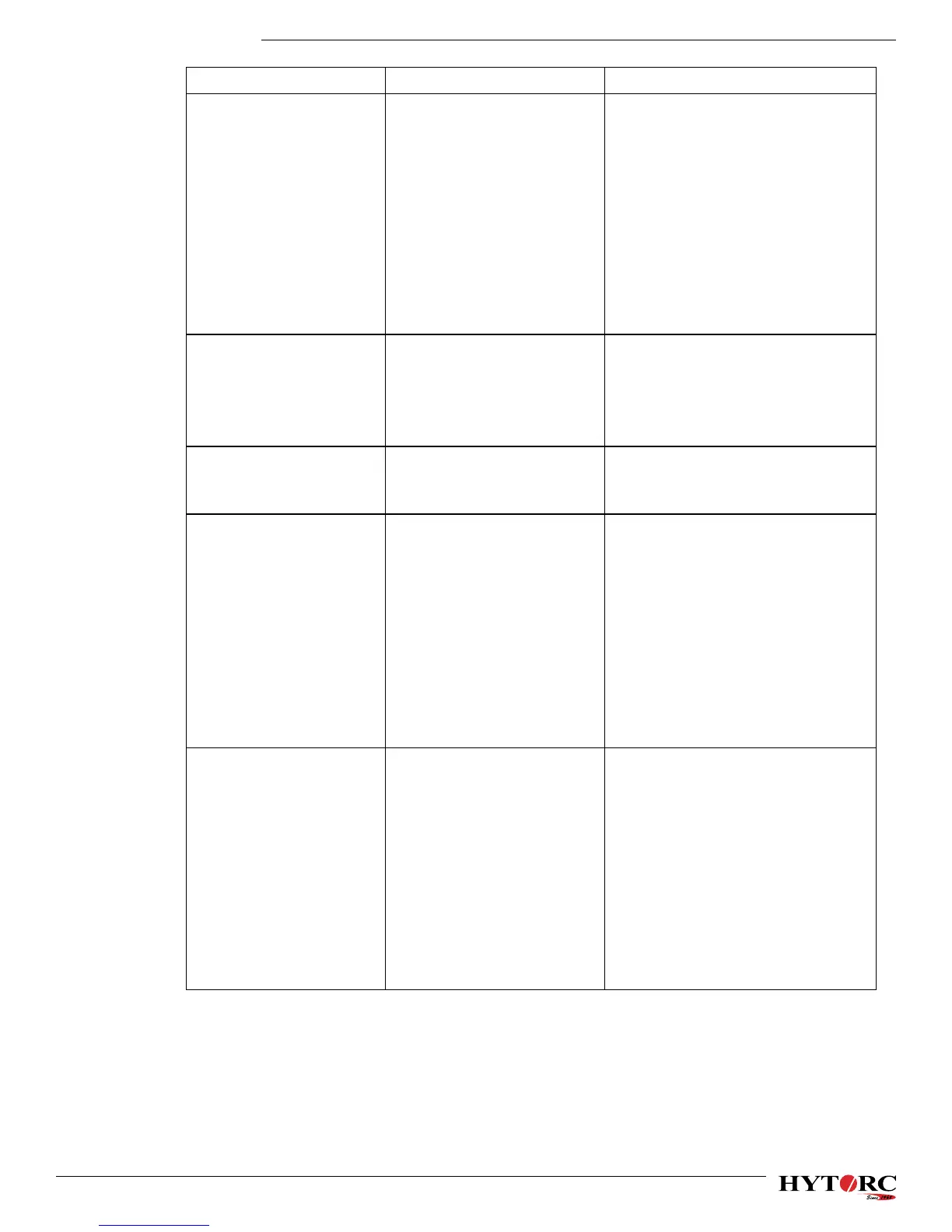

SYMPTOM PROBABLE CAUSE REQUIRED ACTION

Cylinder/Tool leaks

1. Safety relief valve on swivel has lifted.

2. Blown O-ring in cylinder

3. Defective gland seal.

1A. Tighten all hose and couplers. If leak

continues, adjust safety setting - Test #4 (pg. 34)

1B. Check to see if the system is properly plumbed

by running test #5 (pg. 34) (high pressure on

retract side will lift the safety relief valve)

2. Replace O-Ring with proper high pressure

O-Ring. (Call for service)

3. Replace gland seal. (Call for service)

Tool operates backwards 1. Couplings reversed

2. Multiple hoses in even numbers

1. Run test #5. Re-Plumb system as necessary.

2. As plumbed, HYTORC hoses may only be

joined together in odd numbers ONLY. If it is

necessary to use 2,4,6 hoses - make an adapter

from spare high pressure couplings and nipples.

Ratchet returns with retract stroke

1. Broken or otherwise inoperable drive

segment.

1. Replace drive segment and/or spring. (Call

for service)

Ratchet will not take successive

strokes

1. Broken or otherwise inoperative drive

segment I or spring

2. Cylinder not retracting completely

3. Linkage between piston rod and drive

plates is broken

1. Replace drive segment and/or spring. (Call

for service)

2. Remove tool from nut and cycle freely for

several strokes. If problem persists, check pawls.

2A. Operator not allowing adequate time for

cylinder to retract fully.

3. Replace parts as necessary - (Call for service)

Tool locks onto nut

1. Drive segment is loaded when the

tool is maxed out in torque

2. Tool is operating backwards

3. Tool is wedged under a fixed object

1. Press advance button on remote and build

pressure - continue to press down on remote while

pulling back on one of the accuracy assurance

levers - release remote while continuing to hold

back on levers

2. Push advance button down - tool should

immediately fall free- Run test #5 (pg. 34)

3. Remove shroud from around ratchet. Using

any tool available, pry the drive segment out of

the ratchet and at the same time pull back on the

accuracy assurance levers. Tool should swing free

or burn away the socket or obstruction.

(Continued on following page.)

Loading...

Loading...