Page 111 of 116

©HALE PRODUCTS, INC. Our policy is one of continuous development. We therefore

reserve the right to amend specifications without notice or obligation.

Cooling water from the heat exchanger

designed to cool the compressor is

plumbed to the tank. When not running

CAFS (i.e. drafting), the tank can overfill.

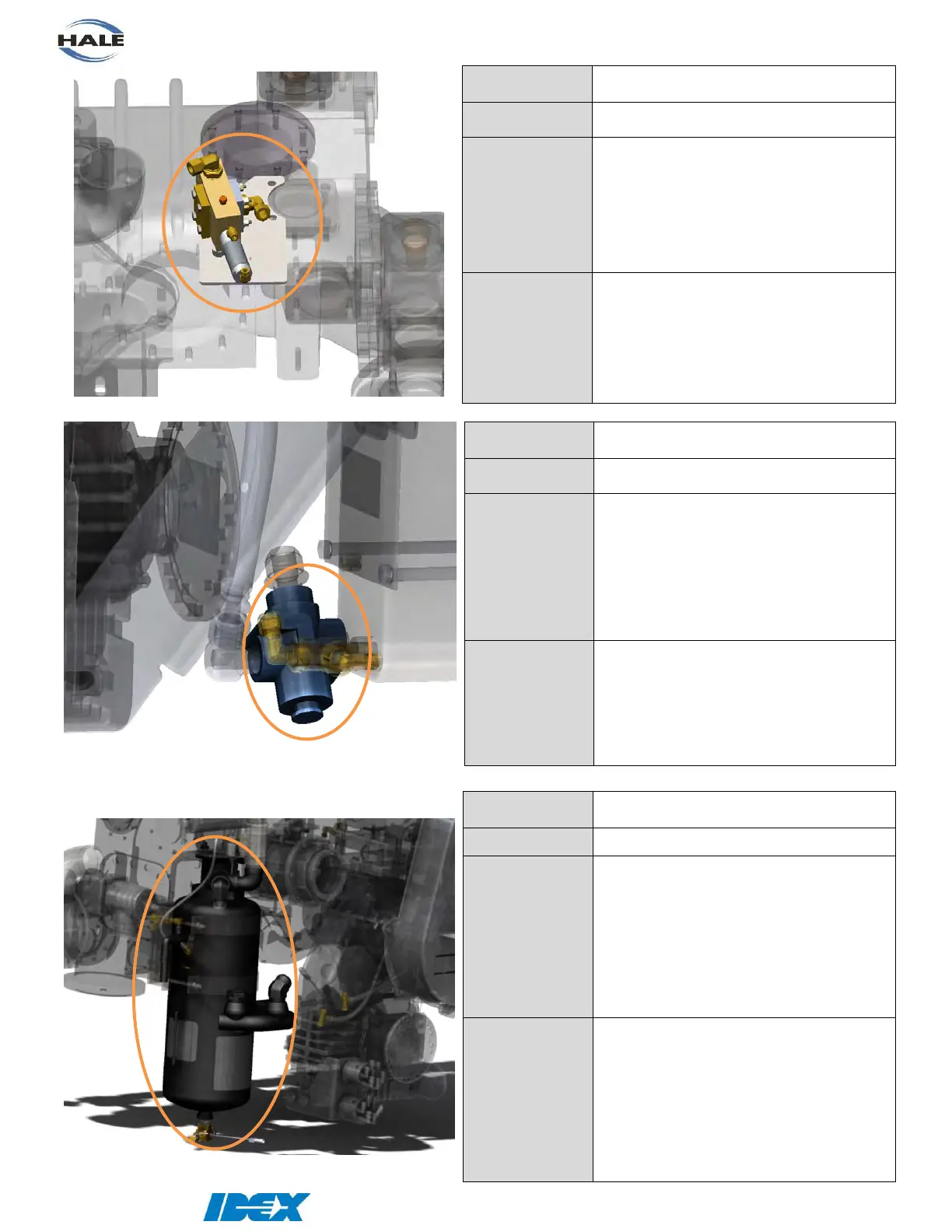

This solenoid/valve assembly is designed

to be flowing when the clutch solenoid is

engaged.

• Not opening

o No air to 4-way valve.

o Air ports clogged.

o No signal from clutch solenoid.

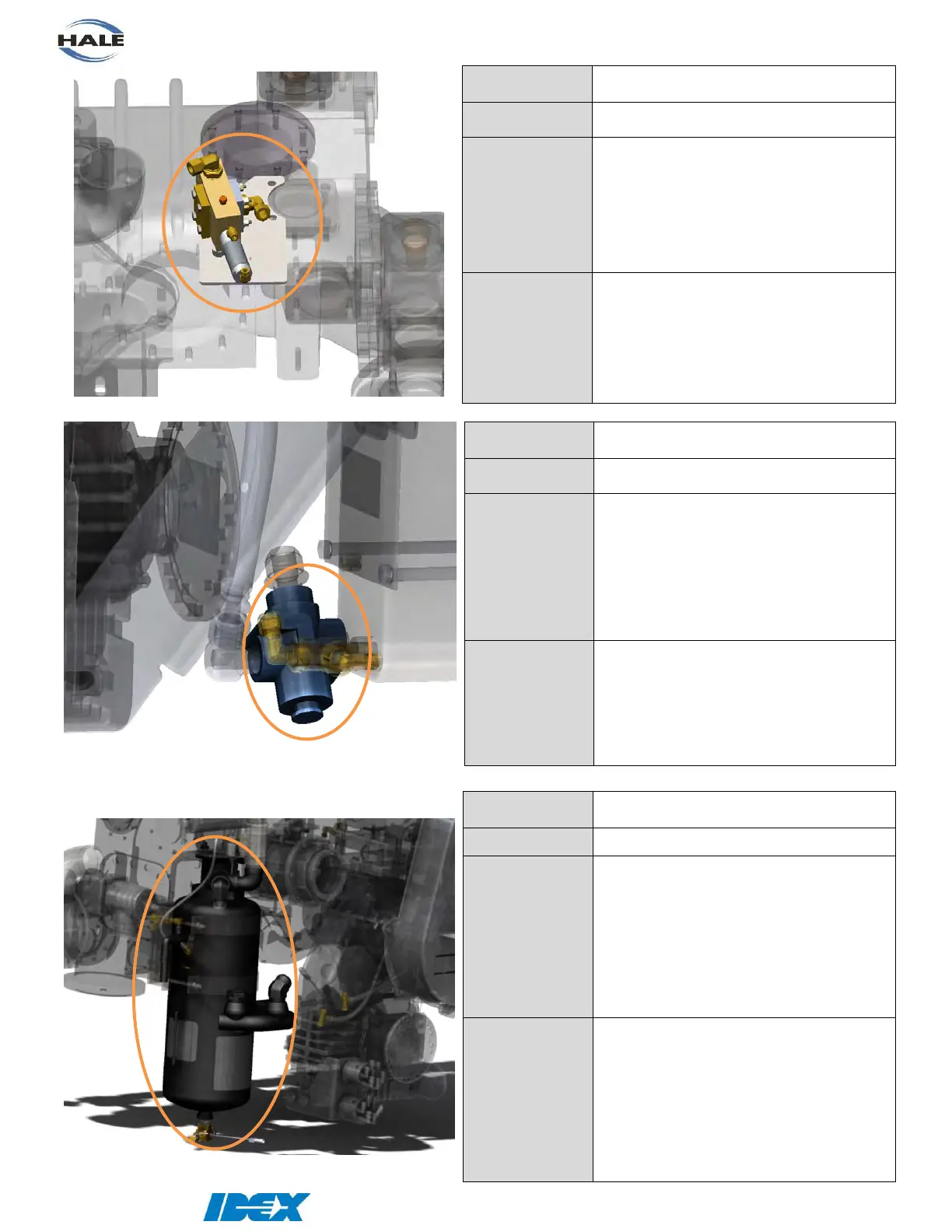

Thermostatic Oil Bypass Valve

Opens at 150°F (65°C) [fully opening at

170°F (76°C)] to allow the oil to run

through the heat exchanger otherwise it

bypasses the heat exchanger.

• Compressor is overheating

o Not fully opening.

o Oil temperature is above max

operating temperature.

Separates the air and oil through a series

of chambers internally and any

condensation/water, which can be

drained from the bottom ball valve. The

side “arm” is for replacing oil. The top port

with the air valve is for discharging air to

the pump or auxiliary port. The hex on the

side supplies air to the control system for

the compressor.

• Compressor is overheating

o Oil is not at proper level.

o Oil not being cooled by Heat

Exchanger.

o Coolant Valve not opening.

• Air injection/Pressure match

o Hex port on side is leaking

o Brass orifice is missing from

scavenge line.

Loading...

Loading...