MAGIS COMBO V2

34

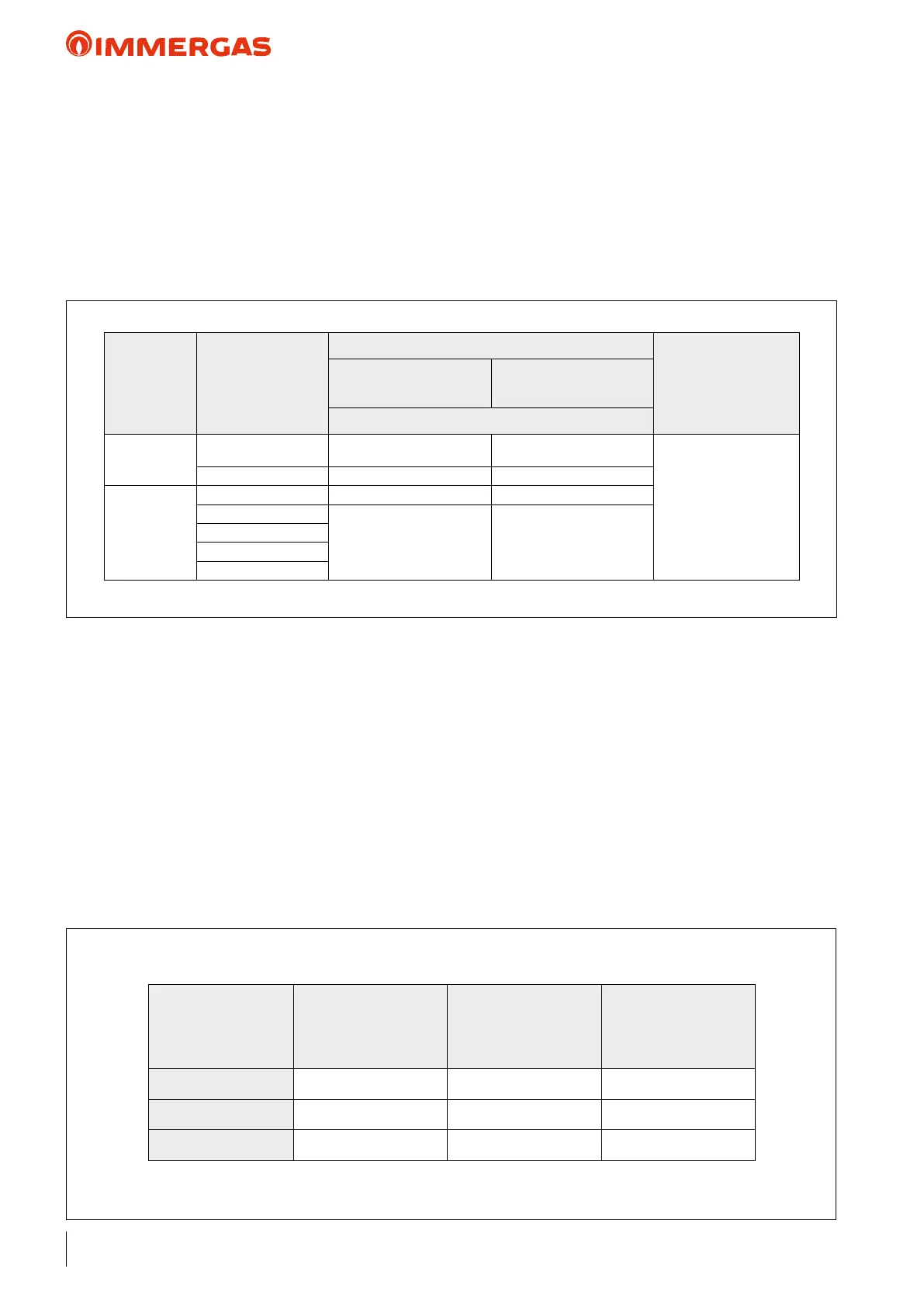

Model

MAGIS COMBO V2

Liquid line pipe external

diameter

(mm - inch)

Maximum length with-

out base load top-up

(liquid line pipe)

Top-up quantity for

every additional metre

of the liquid line pipe

AUDAX PRO 4 V2 Ø 6.35 - 1/4" ≤ 15 m 20 g/m

AUDAX PRO 6 V2 Ø 6.35 - 1/4" ≤ 15 m 20 g/m

AUDAX PRO 9 V2 Ø 6.35 - 1/4" ≤ 15 m 20 g/m

NOTE: If you have already prepared chiller pipes on the 3/8"

(Ø 9.52 mm) instead of 1/4" (Ø 6.35 mm) liquid line, it should

be noted that up to 7 m the machine works correctly without

having to add coolant gas, if you exceed this length, you must

add 50 g/m linear, but never exceed the total charge of 1.84 kg

of R32 coolant (take into account the amount already preloaded

in the machine).

N.B.: To avoid breaking the compressor, do not top-up the

coolant beyond the specied amount.

Topping up the coolant load.

Below is the default factory base load:

MAGIS COMBO V2 models with R32 coolant gas:

- AUDAX PRO 4 V2 = 1.2 kg

- AUDAX PRO 6 V2 = 1.2 kg

- AUDAX PRO 9 V2 = 1.4 kg

e top-up depends on the total length and diameter of the pipes.

All the default factory loads are determined as follows, depending

on the standard length of the pipes (see table below).

If the used pipes are longer than stated below, the load must

be topped-up in the manner and quantities described in the

instruction manual supplied with the product.

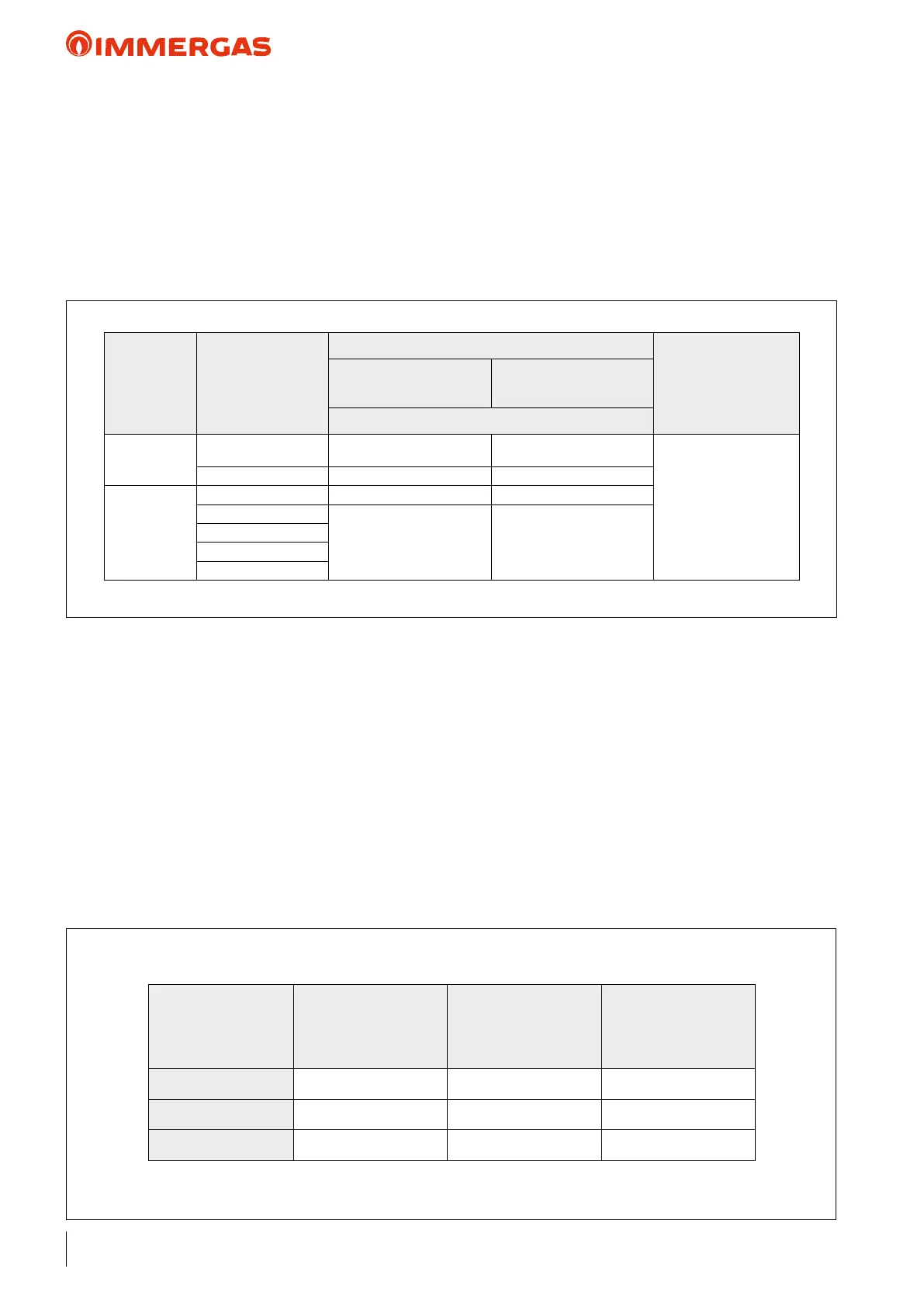

Line Pipe diameter (mm)

Insulation thickness

Notes

Standard conditions

(Less than 30 °C, RH 85%)

High humidity conditions

(Exceeding 30 °C, RH 85%)

EPDM, NBR

Liquid

Ø 6.35 - 19.05 9 9

e pre-selected ma-

terial must be able to

withstand temperatures

exceeding 120°C

Ø 12.70 - 19.05 13 13

Gas

Ø 6.35 13 19

Ø 9.52

19 25

Ø 12.70

Ø 15.88

Ø 19.05

NOTE: e insulation cannot be interrupted and for this reason,

its junctions must be sealed with adhesive to prevent moisture

from getting in.

Should the insulation be exposed to sunlight, it must be protected

by wrapping it with electrical tape or material suitable for this

type of application.

e insulation must be laid without its thickness being reduced

in the bends and supports of the pipes.

Selecting chiller line insulation.

- e gas and liquid chiller lines must be insulated with materials

selected based on their respective diameters.

- Standard insulation is required at a temperature of 30°C with

85% relative humidity. Should the thermal-hygrometric con-

ditions of the air be harsher, you must use insulations that can

be selected from the table below.

Loading...

Loading...