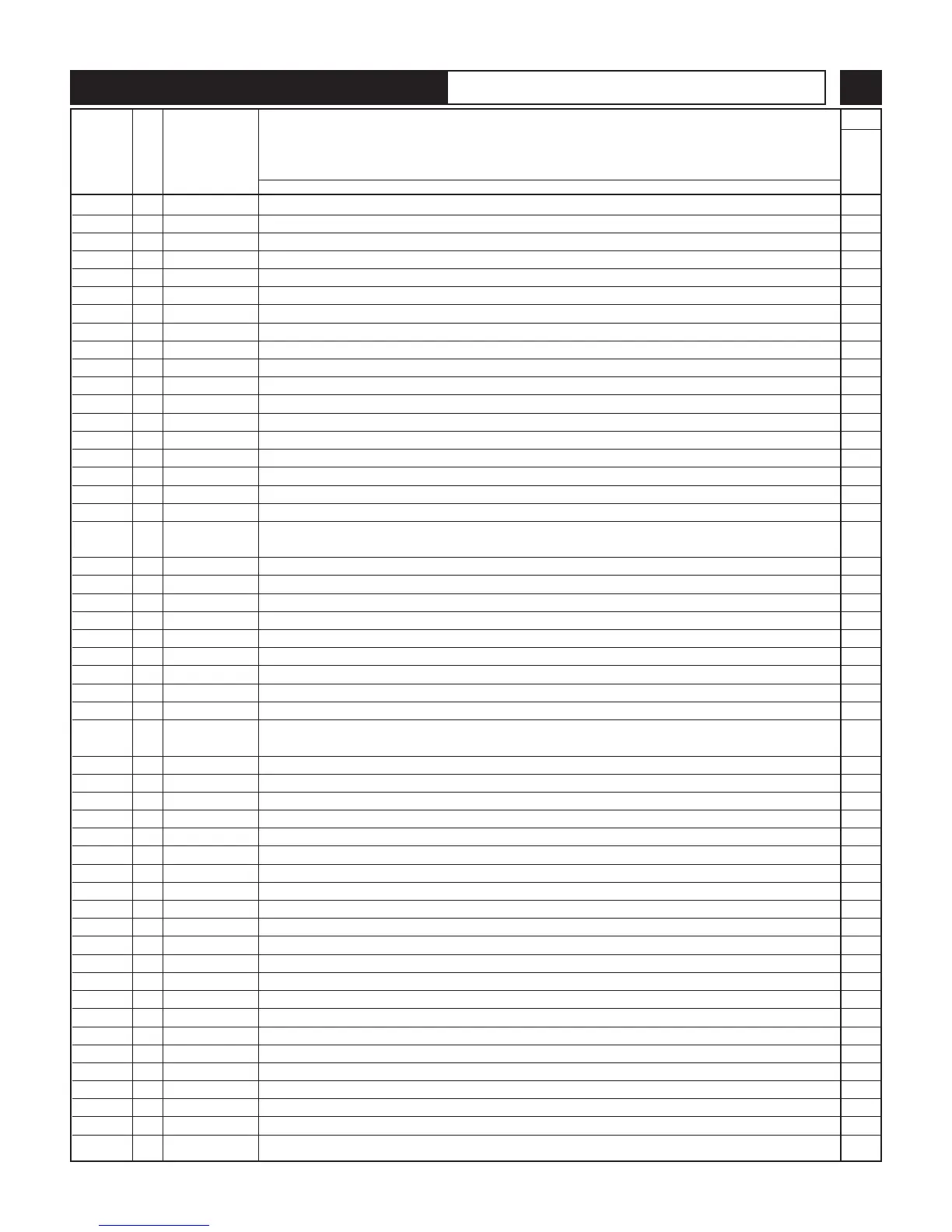

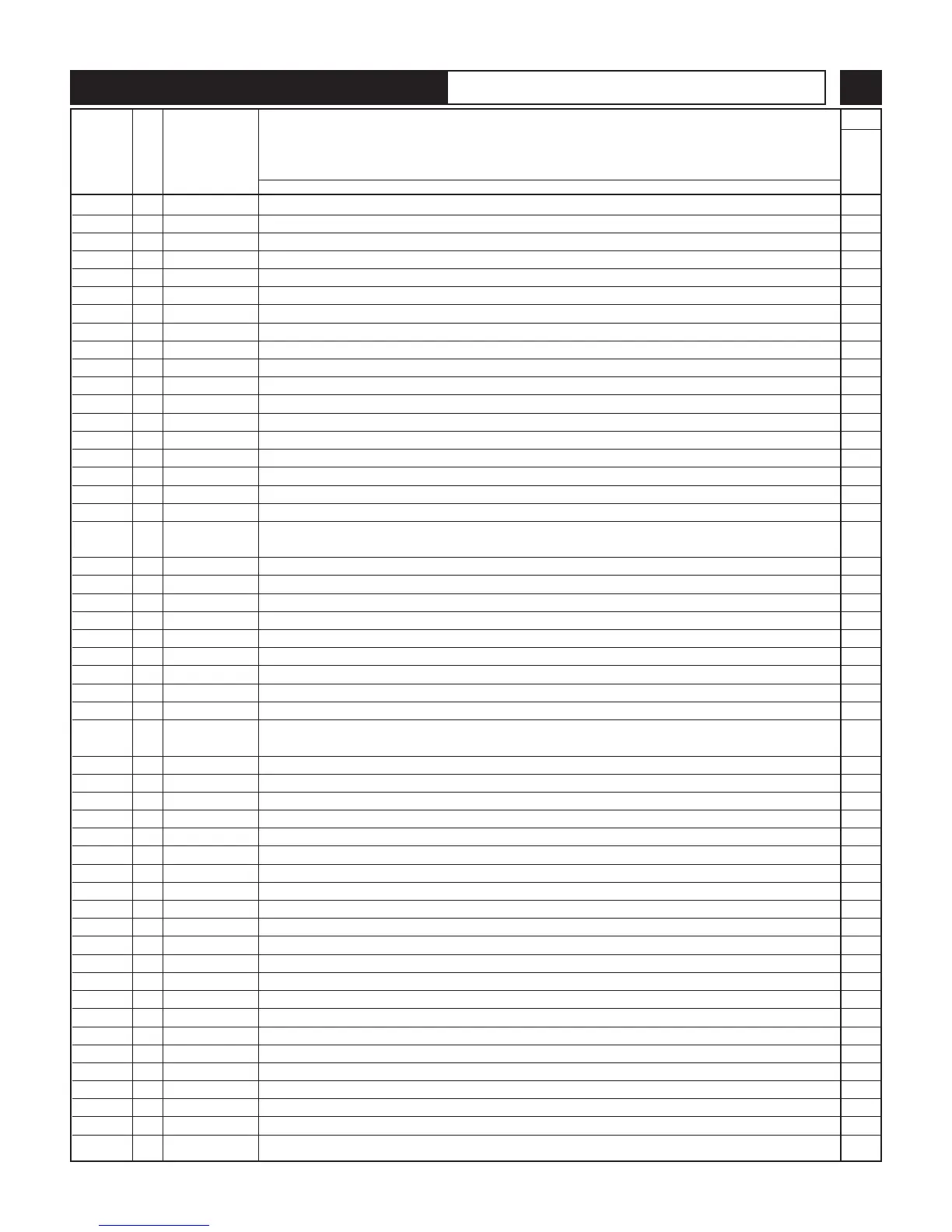

6-4 SECTION 6. GENERAL REFERENCE99903514:TELESCOPIC CRANE:

STATUS

INSPECTION DESCRIPTIONKEYITEM

Inspection Checklist

CRANES

3

20111122

59 l Rotation bearing(s)

60 l Inner boom pivot pin(s) & retainer(s)

61 l Outer boom pivot pin(s) & retainer(s)

62 l Inner boom cylinder pin(s) & retainer(s)

63 l Outer boom cylinder pin(s) & retainer(s)

64 l Extension cylinder pin(s) & retainer(s)

65 l Jib boom pin(s) & retainer(s)

66 l Jib cylinder pin(s) & retainer(s)

67 l Jib extension cylinder pin(s) & retainer(s)

68 l Boom tip attachments

69 l Other

Q 70 Hyd Lines Hoses, fittings & tubing for proper routing, leakage, blistering, deformation & excessive abrasion.

71 l Pressure line(s) from pump to control valve

72 l Return line(s) from control valve to reservoir

73 l Suction line(s) from reservoir to pump

74 l Pressure line(s) from control valve to each function

75 l Load holding valve pipe(s) and hose(s)

76 l Other

Q 77 Pumps Pumps & motors for loose bolts/fasteners, leaks, noise, vibration, loss of performance,

& Motors heating & excess pressure.

78 l Winch motor(s)

79 l Rotation motor(s)

80 l Other

Q 81 Valves Hydraulic valves for cracks, spool return to neutral, sticking spools, proper relief valve setting, relief valve failure.

82 l Main control valve

83 l Load holding valve(s)

84 l Stabilizer or auxiliary control valve(s)

85 l Other

86 l Other

Q 87 Cylinders Hydraulic cylinders for drifting, rod seal leakage & leakage at welds.

Rods for nicks, scores & dents. Case for damage. Case & rod ends for damage & abnormal wear.

88 l Stabiliizer cylinder(s)

89 l Inner boom cylinder(s)

90 l Outer boom cylinder(s)

91 l Extension cylinder(s)

92 l Rotation cylinder(s)

93 l Jib lift cylinder(s)

94 l Jib extension cylinder(s)

95 l Other

Q 96 Winch Winch, sheaves & drums for damage, abnormal wear, abrasions & other irregularities.

Q 97 Hyd Filters Hydraulic filters for replacement per maintenance schedule.

A 98 Daily All daily inspection items.

A 99 Monthly All monthly inspection items.

A 100 Quarterly All quarterly inspection items.

A 101 Hyd Sys Hydraulic fluid change per maintenance schedule.

A 102 Controls Control valve calibration for correct pressures & relief valve settings

A 103 Valves Safety valve calibration for correct pressures & relief valve settings.

A 104 Valves Valves for failure to maintain correct settings.

A 105 Rotation Sys Rotation drive system for proper backlash clearance & abnormal wear, deformation & cracks.

A 106 Lubrication Gear oil change in rotation drive system per maintenance schedule.

A 107 Hardware Check tightness of all fasteners and bolts.

A 108 Wear Pads Wear pads for excessive wear.

A 109 Loadline Loadline for proper attachment to drum.

= SATISFACTORY

R = RECOMMENDATION (Should be

considered for corrective action)

NA = Not Applicable

X = Deficient (Note: If a deficiency is found, an immediate

determination must be made as to whether the deficiency

constitutes a safety hazard and must be corrected prior to

operation.)

FREQUENCY

, R,

X, NA

Loading...

Loading...