INDUSTRIAL INDEXING SYSTEMS, INC. IB-11B012

MOTION CONTROL SYSTEM, MSC-250 USER'S GUIDE

AUGUST 1998 INSTALLATION 2 - 5

the use of resistors, diodes, and suppressors. These must be supplied by the customer.

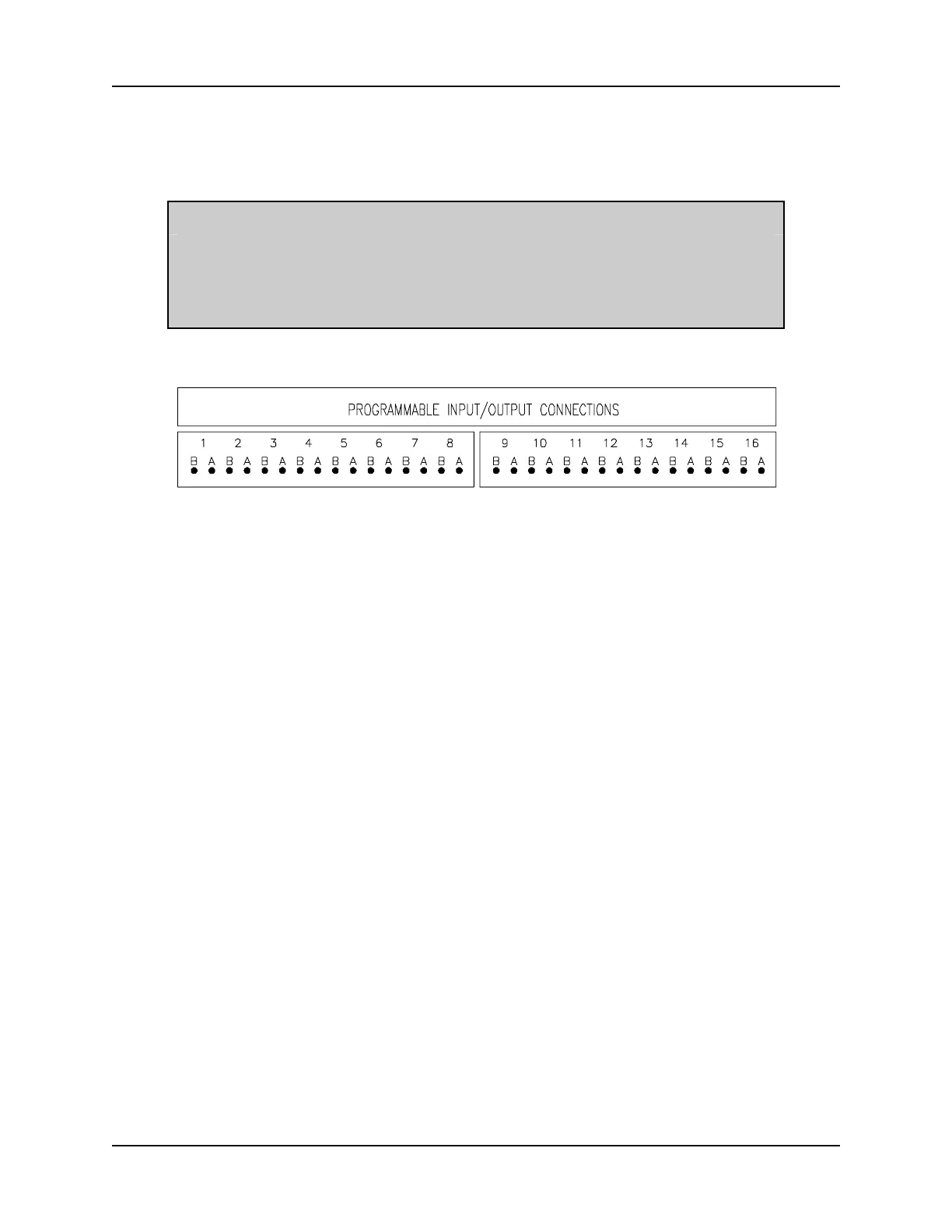

An illustration on the bottom of the MSC-250 front panel shows the appropriate connection

points for the "A" and "B" terminals of each I/O module location (refer to Figure 2.3).

NOTE

The sixteen module locations on the controller or either IOE-850 I/O

Expander may also be used as programmable limit switches. Refer

to the IOE-850 I/O Expander Instruction Manual and Macroprogram

Development System Instruction Book for additional information.

Figure 2.3 - Programmable Input/Output Connections Label

1. Insert the appropriate input or output module in each assigned I/O module

location.

2. If using one or two IOE-850 I/O Expanders, attach the appropriate cables to

daisy-chain the modules to the MSC-250 controller and to each other.

3. Make the proper system connections between the input and output devices and

the "A" and "B" connector locations for each I/O module location.

2.2.2 SYSTEM INTERCONNECTIONS

The system connections for the MSC-250 servo controller will also depend on system

design. Figure 2.4 shows typical system interconnections for the controller, drives, and

encoders. Axis 1 connections are shown with the optional INT-810 interface module. This

module has ribbon cable inputs to match the connectors on the MSC-250 and terminal

outputs to facilitate customer wiring. Axis 2 connections are shown without the interface

module. Such a connection would run direct cables as illustrated.

The pinouts for the encoder cable connector and drive cable connector are shown in

Figure 2.4. These are repeated in the sequence of pinout illustrations which follow along

with the pinouts for the communication ports. The balance of these instructions assume all

ports and connectors are used although this may not be the actual case.

Loading...

Loading...