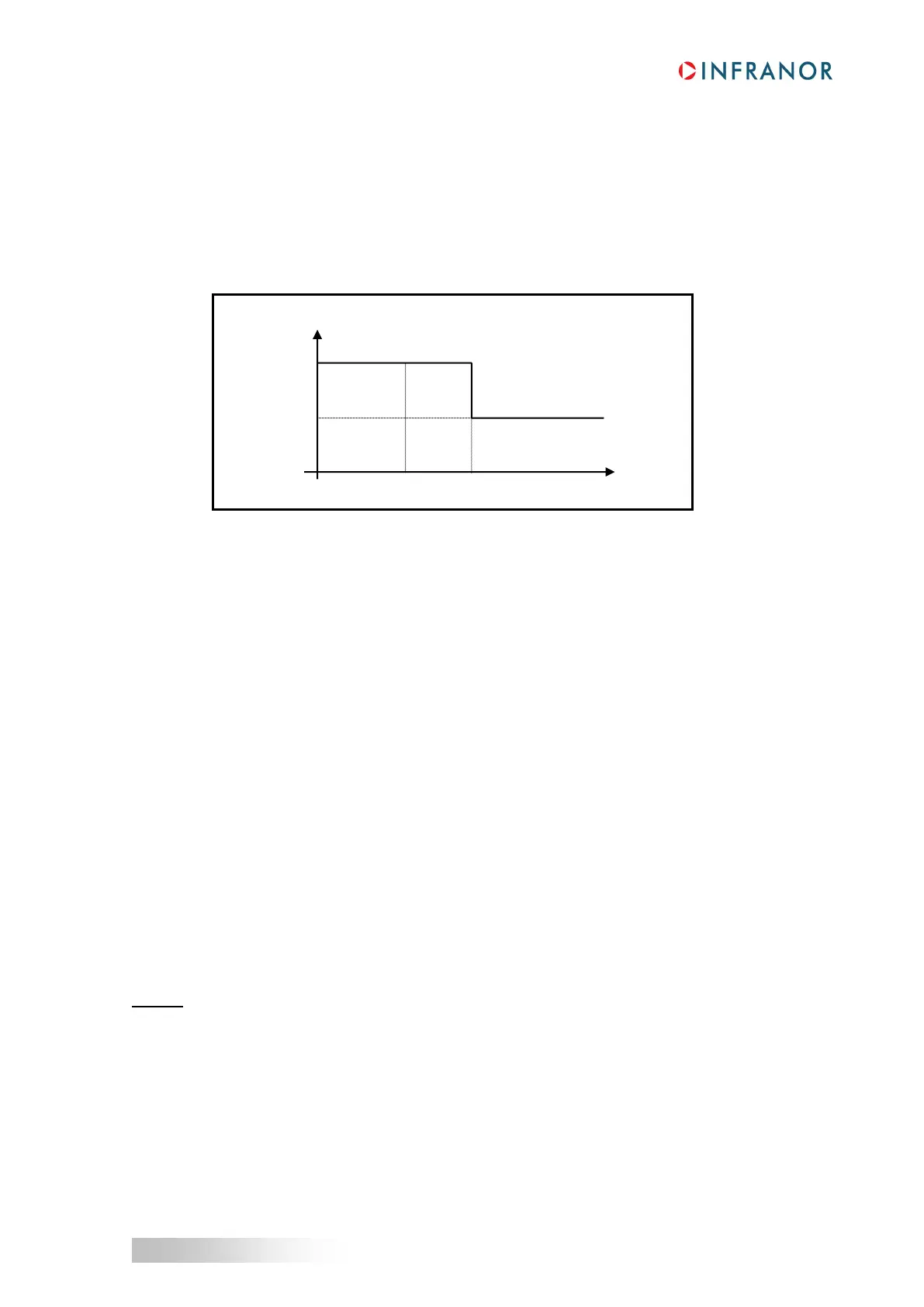

3.2.2 - OPERATION OF THE CURRENT LIMITATION IN LIMITING MODE

When the drive output RMS current (I

2

t) reaches 85 % of the rated current, the I²t fault LED on the drive front

panel is blinking (t1 in the diagram). When the RMS current (I

2

t) drops below 85 % of the rated current, the

blinking is inhibited.

When the drive output RMS current (I

2

t) reaches the rated current value, the I

2

t protection limits the drive output

current at this value (t2 in the diagram).

Diagram of the drive output current limitation in an extreme case (motor overload or shaft locked):

The maximum current duration before release of the blinking display (t1 - t0) and before limitation at the rated

current (t2 - t0) is calculated the same way as in the "Fusing" mode.

3.3 - ENCODER COUNTING PROTECTION

When servo motors are equipped with an encoder feedback, any error in the encoder pulses counting is

generating a rotor position measurement error and may involve uncontrolled motor movements that may be

dangerous for operator and machine. The encoder counting protection available in the XtrapulsCD1-a drive range

allows the detection of pulse counting errors and immediately disables the drive for safety reasons.

The encoder counting protection is checking that the number of encoder pulses between two successive Z marker

pulses (or R reference signals) is equal to the Motor encoder resolution value multiplied by the Zero mark pitch

parameter value. The encoder counting protection is also checking that the encoder pulses frequency is lower

than 1.5 times the maximum encoder frequency. The maximum encoder frequency is calculated in the drive

according to the Motor encoder resolution parameter value and the Maximum speed parameter value.

The Motor encoder resolution parameter value defines the number of encoder pulses (or encoder signal

periods) per motor revolution (for a rotary motor) or per motor pole pairs (for a linear motor).

The Zero mark pitch parameter value defines the number of motor revolutions (for a rotary motor) or of motor

pole pairs (for a linear motor) between two successive Z marker pulses (or R reference signals).

For a rotary motor, the Zero mark pitch parameter is generally equal to 1 because the encoder has got one Z

marker pulse (or R reference signal) per motor revolution.

For a linear motor with only one marker pulse over the entire motor travelling range, the parameter Zero mark

pitch must be set at 15. In this, case the encoder counting protection is checking that the measured encoder

position has always got the same value when the marker pulse is activated (no position measurement drift).

Remark: In the Incremental encoder configuration without HES, after a Counting fault release, it is necessary

to renew the motor Phasing procedure because the current rotor position reference for the motor commutation is

not correct.

Loading...

Loading...