- 48 -

2 System Commissioning

2

Performance adjustment of system control

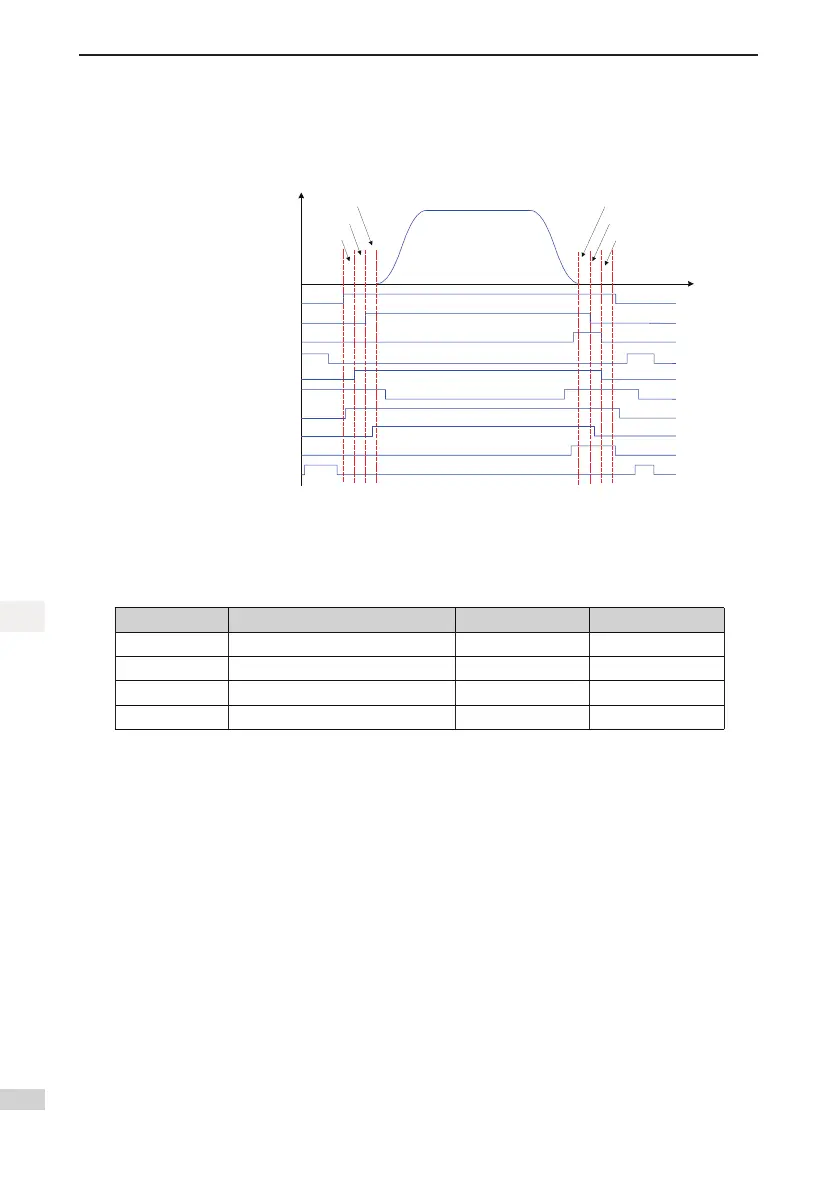

Figure 2-6 Running time sequence

V (speed)

t (time)

F2-16

F3-18

F3-19

F3-20

F8-11

F2-17

RUN contactor

Brake contactor

Shorting door lock circuit contactor

Shorting PMSM stator contactor

Internal running status

Leveling signal

RUN contactor feedback

Brake contactor feedback

Shorting door lock circuit

contactor feedback

Shorting PMSM stator

contactor feedback

1. Riding comfort adjustment at elevator startup and stop

The parameter setting related to riding comfort adjustment at elevator startup and stop is described in

the following table.

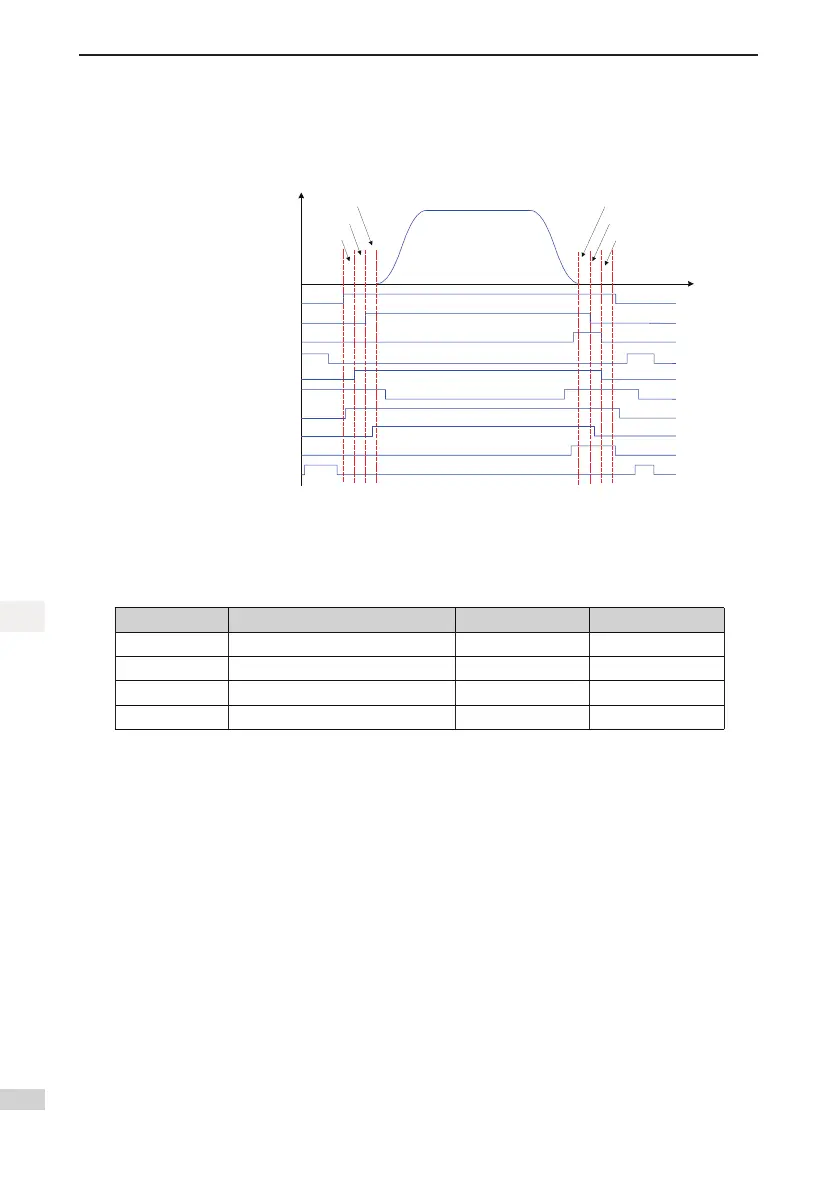

Parameter No. Parameter Name Setting Range Default

F2-00 Speed loop proportional gain Kp1 0–100 40

F2-01 Speed loop integral time Ti1 0.01–10.00s 0.60s

F2-03 Speed loop proportional gain Kp2 0–100 35

F2-04 Speed loop integral time Ti2 0.01–10.00s 0.80s

1) Adjustment to abnormal motor startup

F2-00, F2-01, F2-03 and F2-04 are used to adjust the speed dynamic response characteristics

of the motor.

• To achieve a faster system response, increase the proportional gain and reduce the

integral time. However, too large proportional gain or too small integral time may lead to

system oscillation.

• Decreasing the proportional gain and increasing the integral time will slow the dynamic

response of the motor. However, too small proportional gain or too large integral time may

cause motor speed tracking abnormality, resulting in fault E33 or instable leveling at stop.

The default setting is proper for most large-power motors, and you need not modify these

parameters. These parameters need to be adjusted only for small-power motors (P ≤ 5.5 kW)

because they may have oscillation. To eliminate oscillation, do as follows:

Decrease the proportional gain rst (between 10 and 40) to ensure that the system does not

oscillate, and then reduce the integral time (between 0.1 and 0.8) to ensure that the system has

quick response but small overshoot.

Loading...

Loading...