Version 3.00 | Optidrive P2 User Guide | 55www.invertekdrives.com

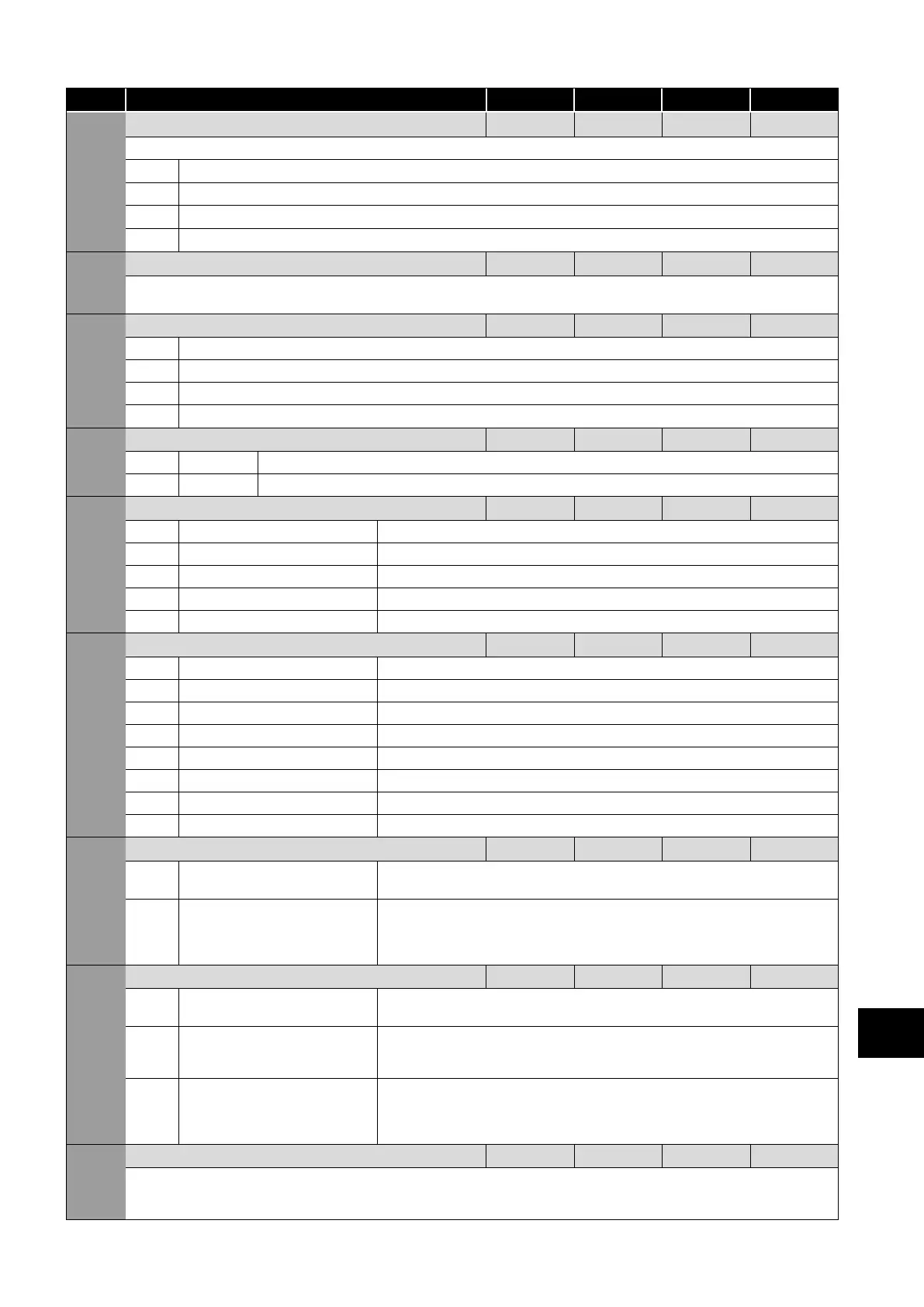

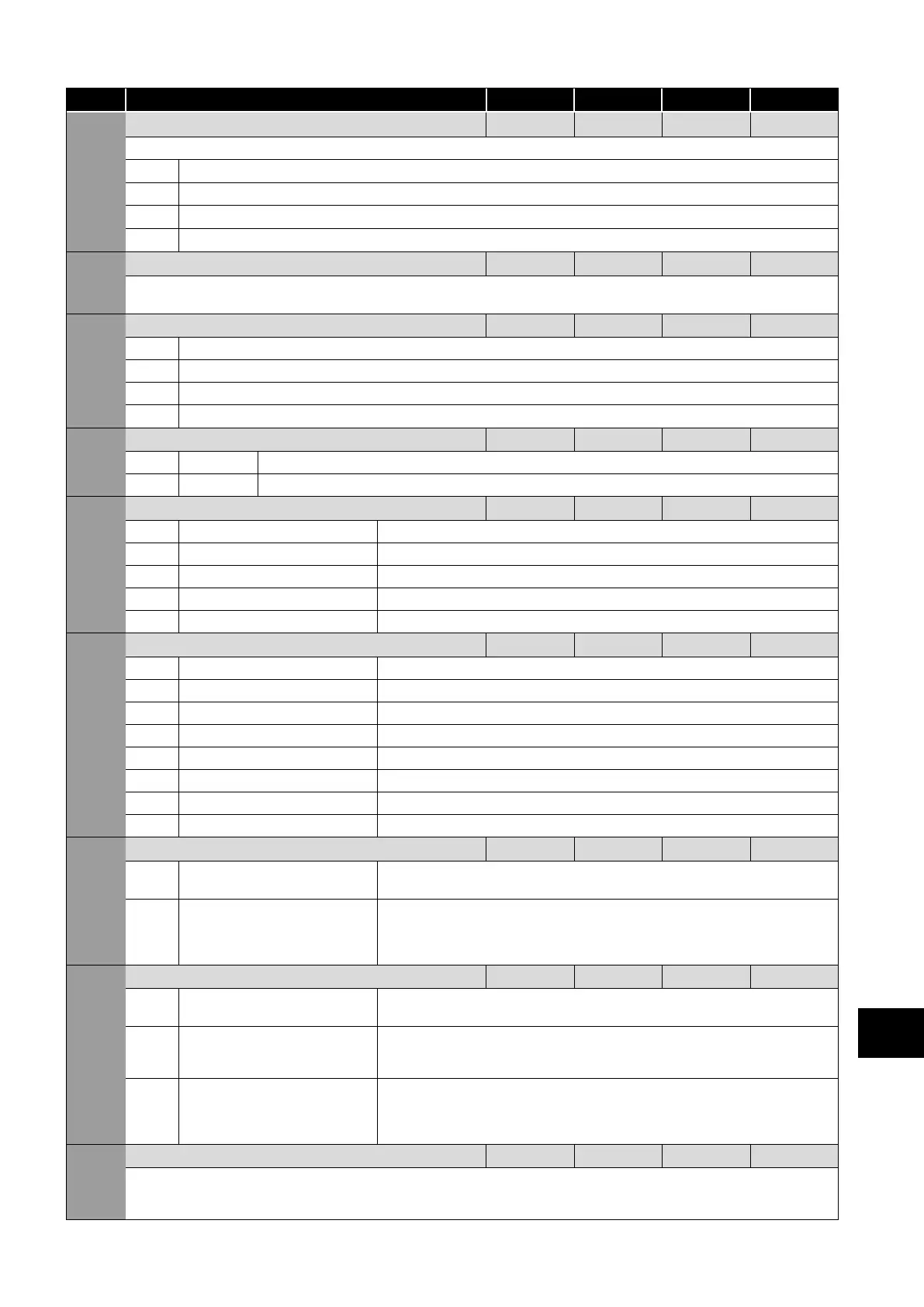

Par Name Minimum Maximum Default Units

P5-04 Modbus RTU / BACnet MSTP Data Format - - - -

Sets the expected Modbus telegram data format as follows:

No Parity, 1 stop bit

No parity, 2 stop bits

Odd parity, 1 stop bit

Even parity, 1 stop bit

P5-05 Communications Loss Timeout 0.0 5.0 2.0 Seconds

Sets the watchdog time period for the communications channel. If a valid telegram is not received by the Optidrive within this time period,

the drive will assume a loss of communications has occurred and react as selected below. Setting to zero disables the function.

P5-06 Communications Loss Action 0 3 0 -

0 Trip & Coast To Stop

1 Ramp to Stop Then Trip

2 Ramp to Stop Only (No Trip)

3 Run at Preset Speed 8

P5-07 Fieldbus Ramp Control 0 1 0 -

0 Disabled Ramps are control from internal drive parameters P1-03 and P1-04.

1 Enabled Ramps are controlled directly by the Fieldbus PDI4 Data Word.

P5-08 Fieldbus Process Data Output Word 4 Select 0 4 0 -

0 Output Torque 0 to 2000 = 0 to 200.0%

1 Output Power Output power in kW to two decimal places, e.g. 400 = 4.00kW

2 Digital Input Status Bit 0 indicates digital input 1 status, bit 1 indicates digital input 2 status etc

3 Analog Input 2 Signal Level 0 to 1000 = 0 to 100.0%

4 Drive Heatsink Temperature 0 to 100 = 0 to 100°C

P5-12 Fieldbus Process Data Output Word 3 Select 0 7 0 -

0 Motor current Output current to 1 decimal place, e.g. 100 = 10.0 Amps

1 Power (x.xx kW) Output power in kW to two decimal places, e.g. 400 = 4.00kW

2 Digital input status Bit 0 indicates digital input 1 status, bit 1 indicates digital input 2 status etc.

3 Analog Input 2 Signal Level 0 to 1000 = 0 to 100.0%

4 Drive Heatsink Temperature 0 to 100 = 0 to 100°C

5 User register 1 User Defined Register 1 Value

6 User register 2 User Defined Register 1 Value

7 P0-80 value User Selected data value

P5-13 Fieldbus Ramp Control 0 1 0 -

0 Fieldbus Ramp Control This option must be selected if the drive acceleration and deceleration ramps are to

be controlled from the fieldbus. P5-07 must also be set to 1 to enable this function.

1 User register 4 The value received by the drive in PDI 4 is transferred to User Register 4. This option

allows the function of the process data word to be defined in Parameter Group 9.

In this case, User Register 4 should not be written to within any PLC function code,

although the value can be read.

P5-14 Fieldbus Process Data Input Word 3 Select 0 2 0 -

0 Torque limit/reference This option must be selected if the drive output torque limit / setpoint is to be controlled

from the fieldbus. This also requires setting P4-06 = 3.

1 User PID reference register This option allows the setpoint to the PID controller to be received from the Fieldbus. In

order for this option to be used, P9-38 must be set to 1, and the PID User setpoint must

not be utilised within the PLC function.

2 User register 3 The value received by the drive in PDI 3 is transferred to User Register 3. This option

allows the function of the process data word to be defined in Parameter Group 9.

In this case, User Register 3 should not be written to within any PLC function code,

although the value can be read.

P5-15 Modbus Response Delay 0 16 0 Chr

Allows the user to configure an additional delay between the drive receiving a request via the Modbus RTU interface, and transmitting a

reply. The value entered represents the delay in addition to the minimum delay permissible according to the Modbus RTU specification,

and is expressed as the number of additional characters.

8

Extended Parameters

Loading...

Loading...