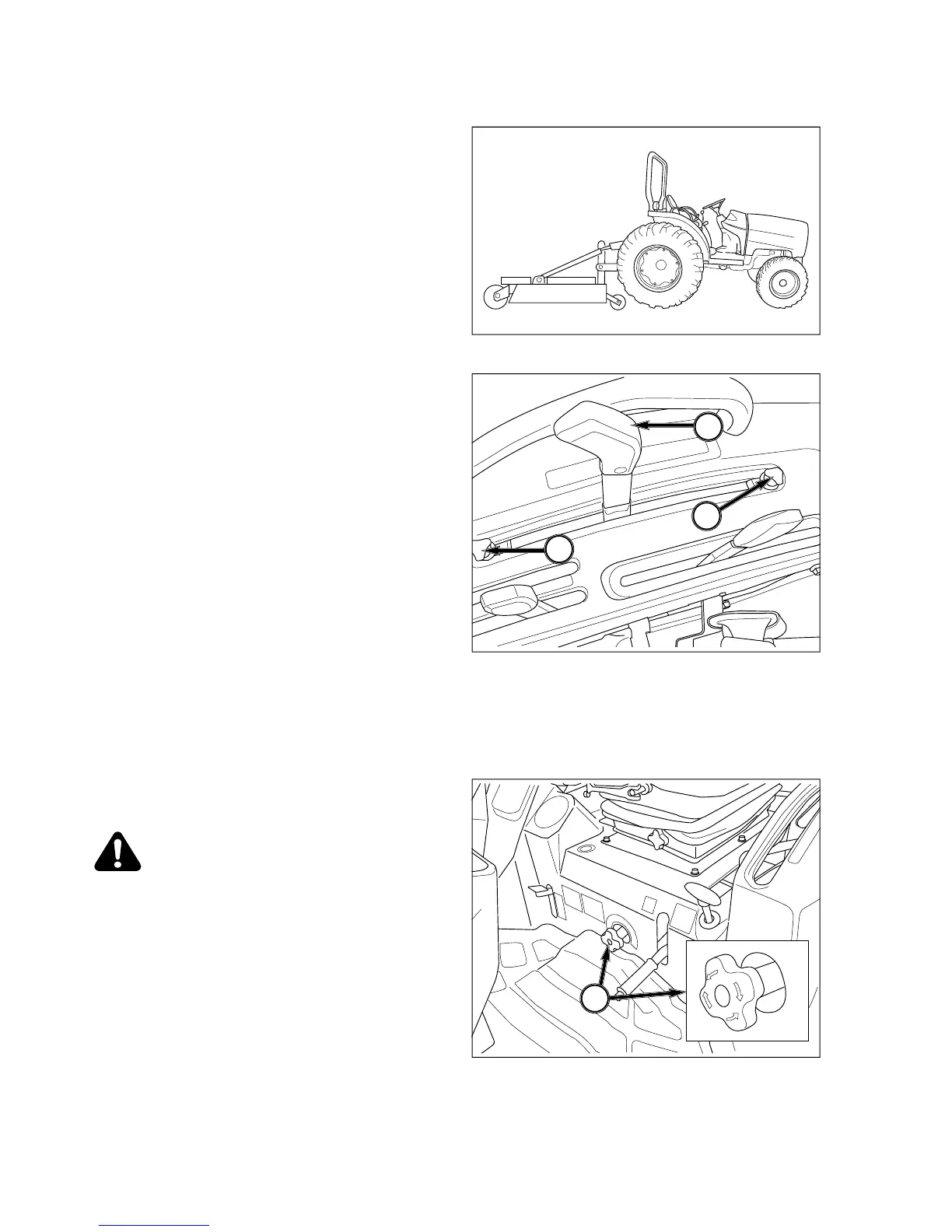

Position Control

FIG. 5-40

imple-

ments and other operations requirin

implement to be

kept at constant hei

round. Also used with

tool bars havin

flexible row units and implements

Lever Positions - Use position control lever,

1, to ad

ust hitch and implement position.

NOTE: Front lever stop, 2, can be set to contac

osition control lever in implement work posi

ion. This enables implement to be returne

o identical position after hitch has been

aised for turning, transporting, etc. Rear le

, can be set to limit raising height,

n Tractor and implement in field

and move position control lever, 1,

ustable stops, 2 and 3, as

- Move position lever, 1, backward

to raise implement. Finish turnin

ainst stop to resume operation.

To Finish Work and Transport - Move position control

rearward in quadrant.

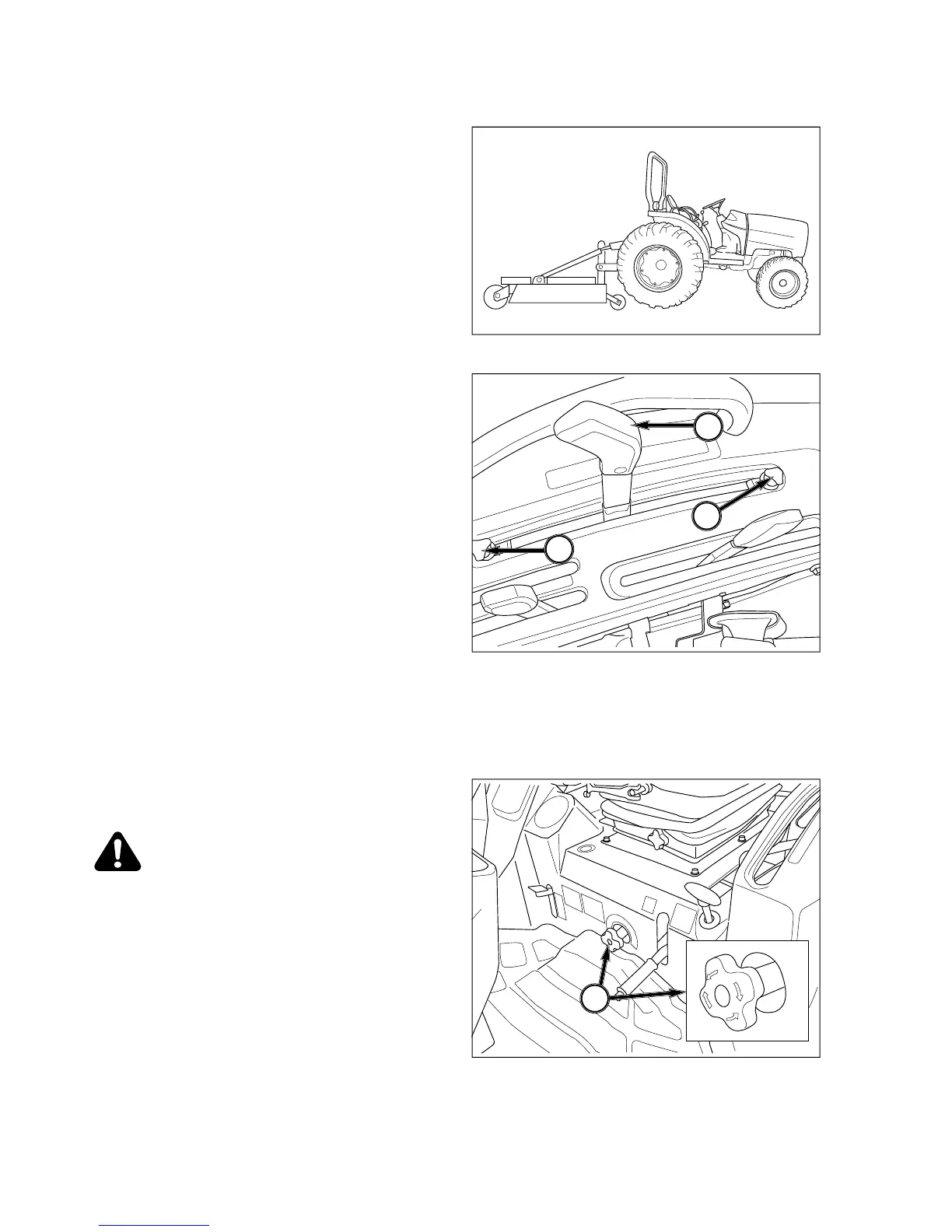

FIG. 5-42

rate control knob, 4.

CAUTION: When usin

ents with PTO driveline, make sure

TO drive shaft has minimum 51 mm

does not bind

drive shaft universal

oints due to extreme

drive shaft an

Loading...

Loading...