FOR MECHANICAL & E6-

HST MODEL

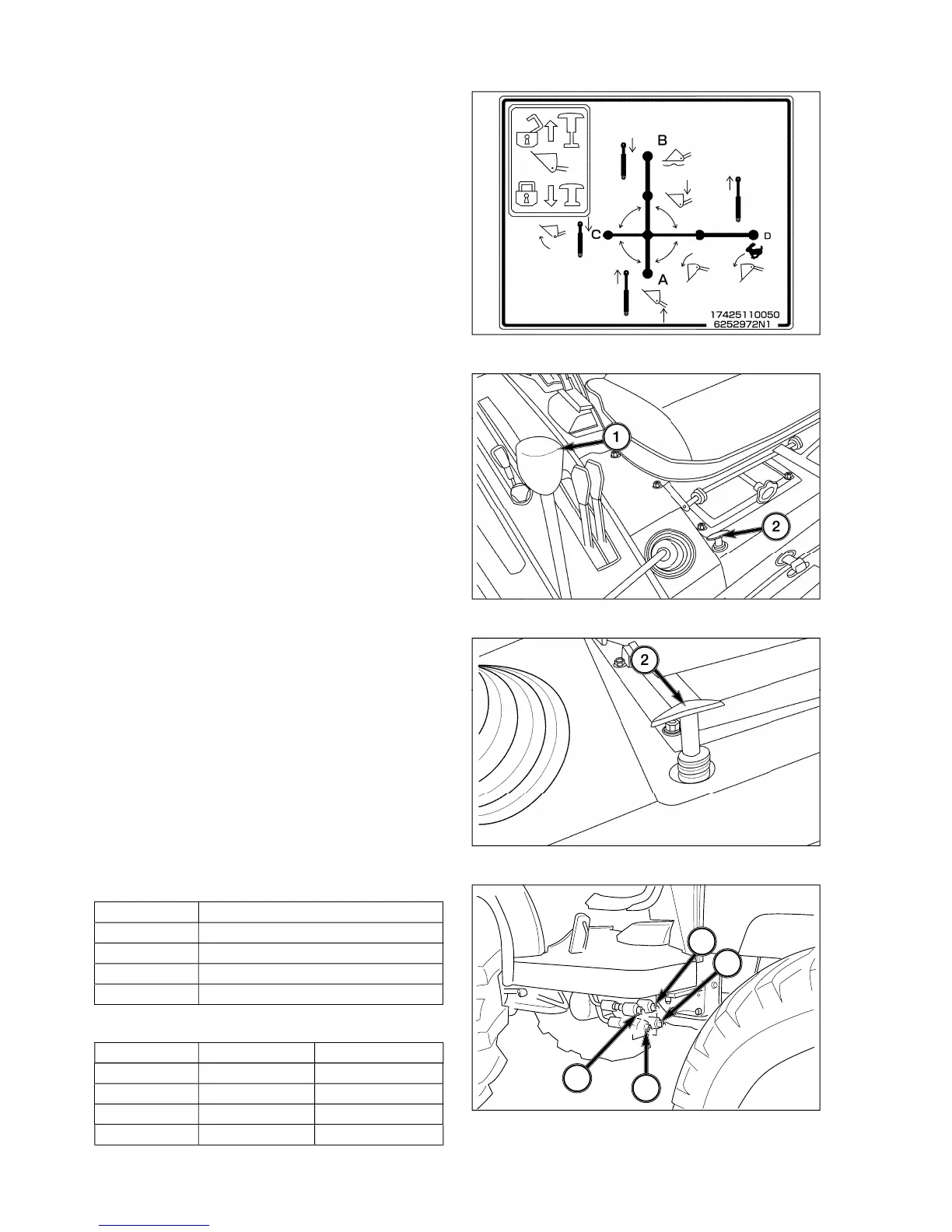

le-lever control, 1, provides

stick”

operation of auxiliar

lever backward and

forward moves the A/B spool in control valve respec-

tivel

orward will retain lever in

osition to allow attachment to follow

lever side-to-side moves the C/D valve spool

and controls Loader bucket position. Pullin

t will curl bucket and pushin

ht will dump

the bucket. Pushin

enerative” position, allowin

. When used with a blade an

can be controlled.

All positions

will return to neutral posi-

tion when lever is released. When in Float, the A/B

valve spool is held b

detents and the lever will have

to be pulled rearward to disen

e the detents.

NOTE: Inabilit

indicate the need for control

od adjustment at base of control lever.

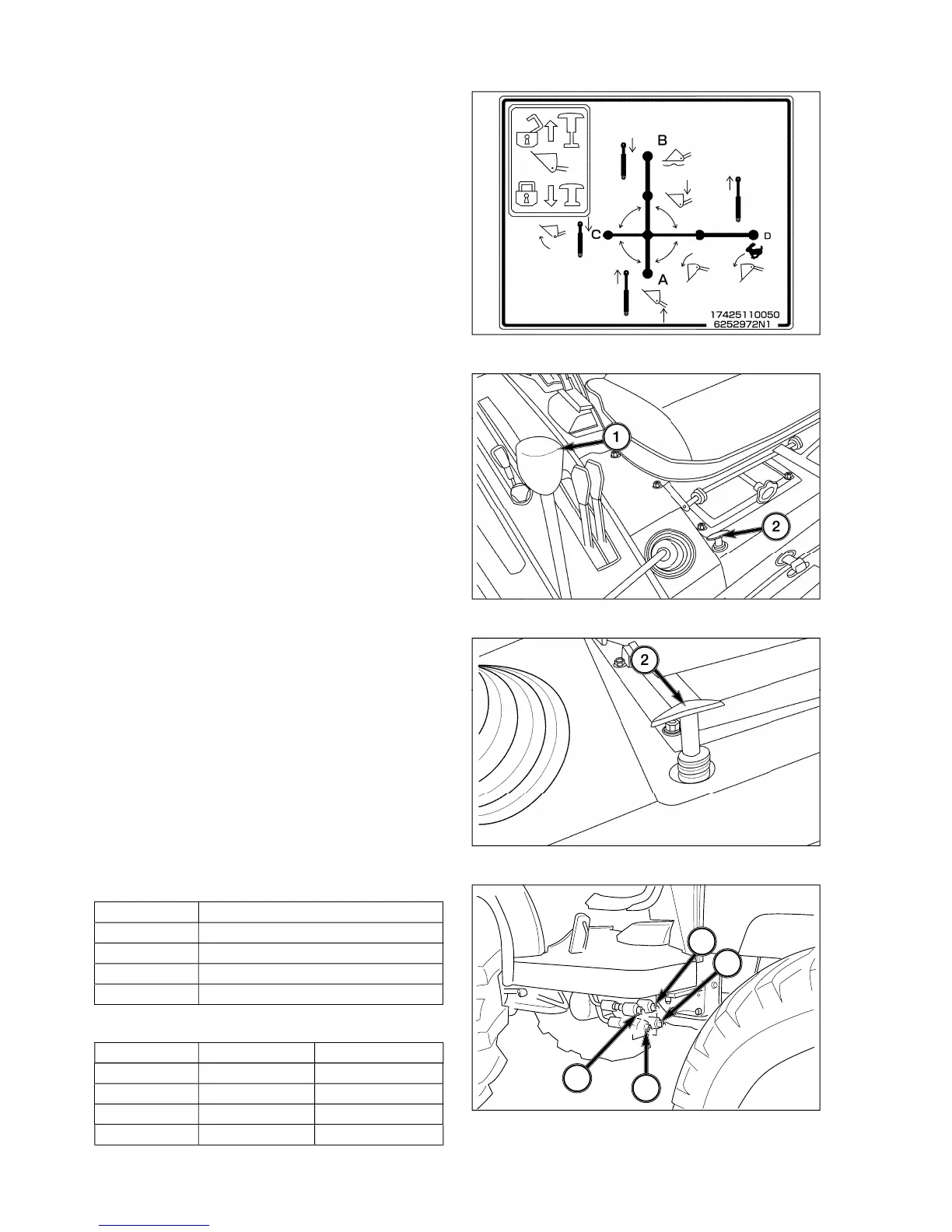

Jo

tick lockout 2 is a T-handle located near the

stick, put T-handle in the down

osition. When the T-handle is in the down position,

the

stick cannot be operated.

To unlock

stick, pull the T-handle up. When the T-

andle is in the up position, the

stick can be operated.

NOTE: If the T-handle is not pulled all the wa

he T-handle will return to the down position

utput ports are located under the ri

ht step.

1. The output ports are identified b

letters, A,B,C,D,

from left to ri

ht as indicated on output ports.

2. The

chart provides correct output port

url

D Bucket Dump and Dump quickl

3. For other operations, except for loader work use the

followin

Loading...

Loading...