Inspection and Installation

1. Confirm that the power switch is in the OFF position and verify that there is

no dangerous voltage on the connection terminals.

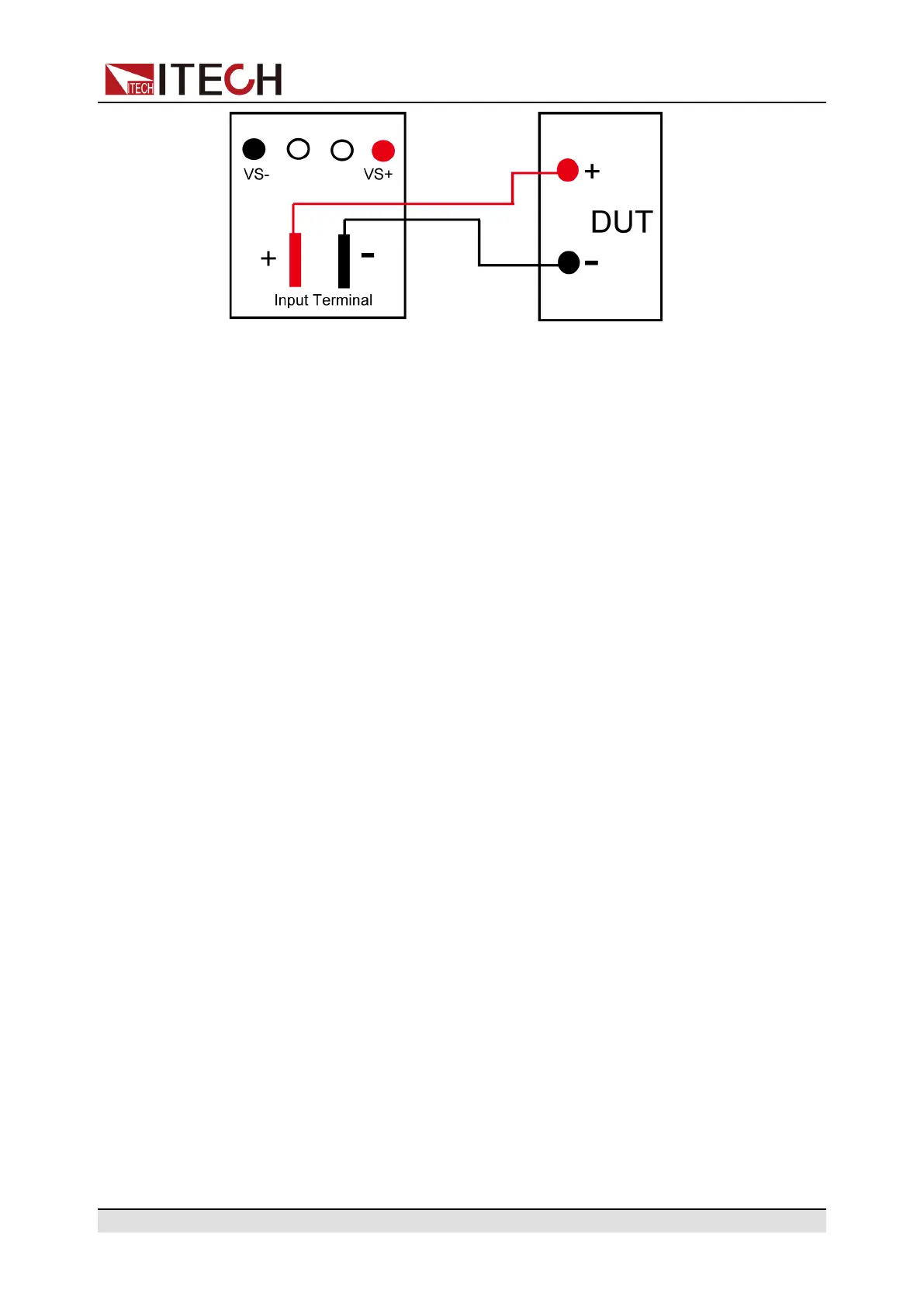

2. Remove the input terminals cover of the load.

3. Loosen the screws of the input terminals and connect the red and black test

cables to the input terminals. Re-tighten the screws.

When maximum current that one test cable can withstand fails to meet the

rated current, use multiple pieces of red and black test cables. For example,

the maximum current is 1,200A, then 4 pieces of 360A red and black cables

are required.

4. Thread the red and black test cables through the input terminals cover of the

load and install the cover.

5. (Optional) According to the actual situation of DUT, connect the grounding

terminal on the rear panel of the instrument to the DUT to ensure the safe

grounding.

For the location information, see 1.5 Rear Panel Introduction.

6. Connect the other end of the red and black cables to the DUT. The positive

and negative poles must be properly connected and fastened when wiring.

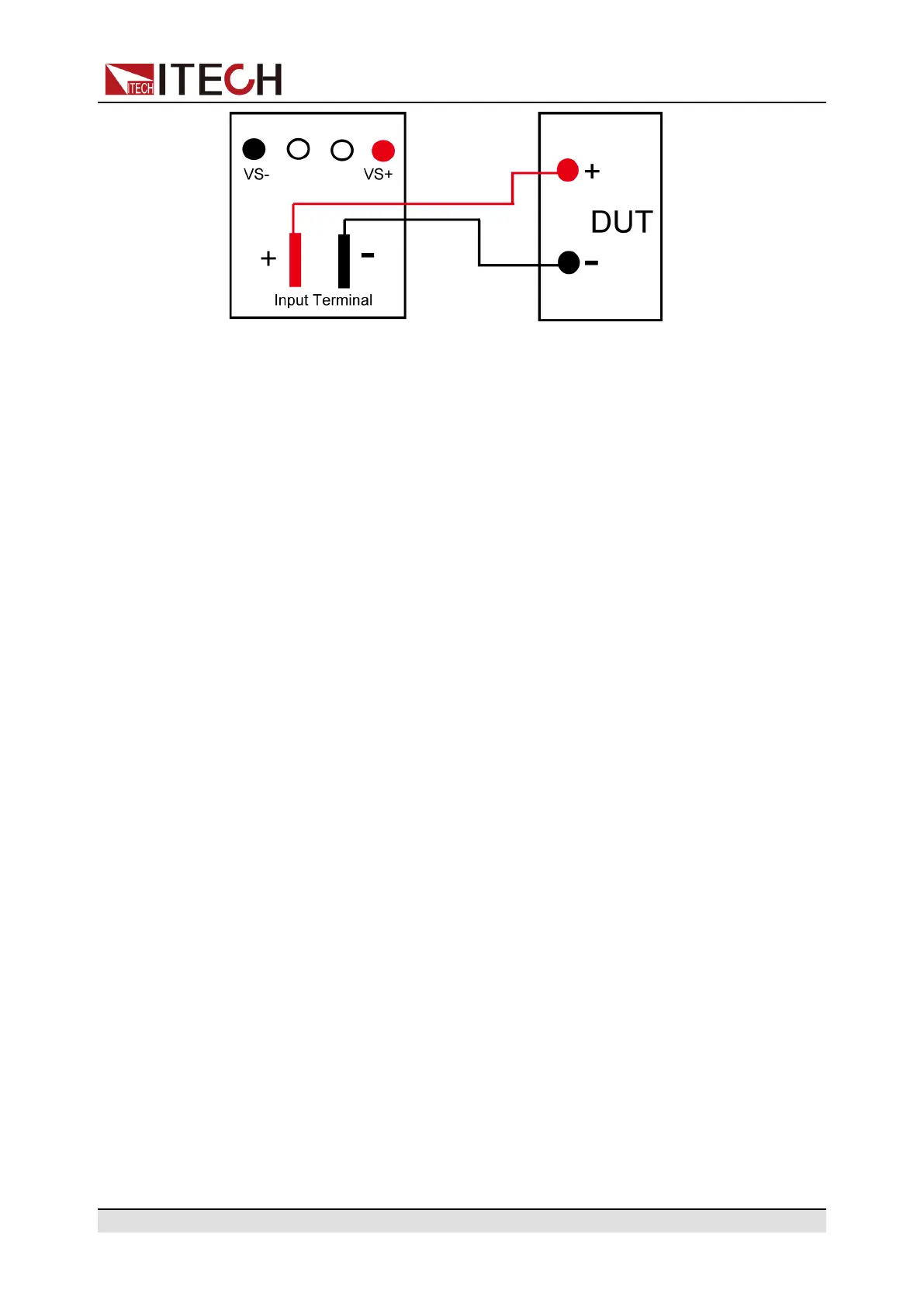

Connecting the DUT (Remote Sensing)

Remote measurement is available for the following scenarios:

When the DUT consumes large current or the wires are too long, there is a volt-

age drop on the wires between DUT and input terminals of the load. To maxi-

mize measurement accuracy, the load provides the remote measurement

terminals VS+ and VS- on the rear panel, which can be used to measure the ter-

minal voltage of the DUT.

When the load is used for battery testing in actual applications, the voltage drop

of the wire will lead to voltage inconsistency of both ends and inconsistency of

the cutoff voltage of load and the actual voltage of battery, resulting in inaccu-

rate measurement.

The connection diagram and steps of remote measurement are as follows:

Copyright © Itech Electronic Co., Ltd.

28

Loading...

Loading...