CHASSIS MODIFICATIONS

2-13

DAILY 4x4

Print 603.93.761 Base - May 2007

Drilling the Chassis

Drillingthe Chassis

2.3 Drilling the Chassis

The frame must not be drilled.

When auxiliary units or c o mponents are to be applied to t he frame, existing factory-made holes must be used and the following

instruct ions must be applied.

Positioning and sizes

If it is necessary to make holes in the frame, it is compulsory to ask IVECO for authorisation.

2.3.1 Screws and nuts

In general, use connectors of the same type and class as those for similar fixings on the original vehicle (Table 2.7).

As a general rule, materials of class 8.8 are recommended. Class 8.8 and 10.9 screws must have been hardened and tempered. For

app lications of diam eter

± 6mm, stainless steel parts are recommended . Approved finishes are Dacromet and zinc coating, as detailed

in Table 2.2. A Dacromet finish is not recommended if the screws are to be subjected to welding. If space allows, use screws and

nuts with fla nge d head s. Use self-locking nuts. Nuts must be tightene d using a torque wrench set to the corre ct torque setting for

the fixing.

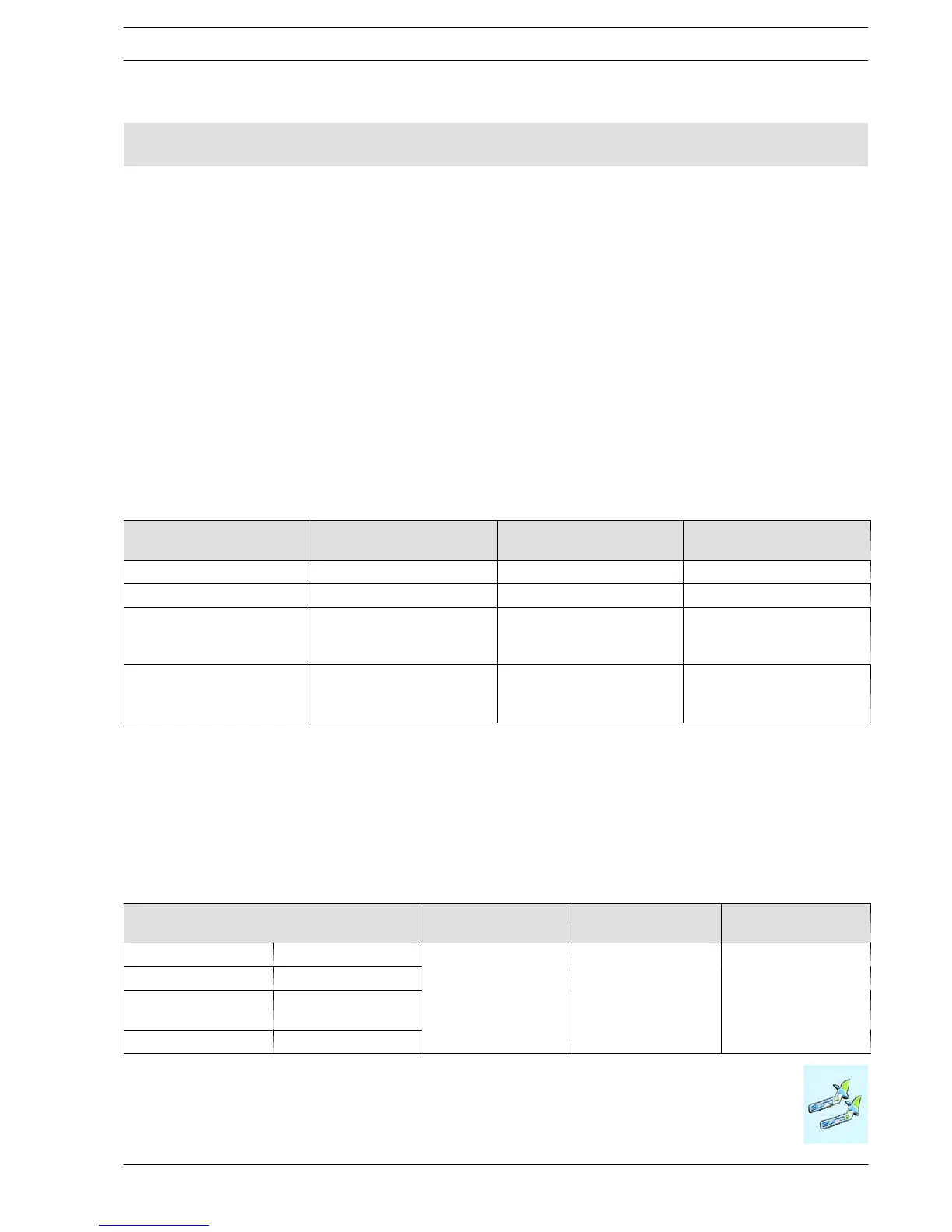

Table 2.7 - Classes of resistance for screws

Class of resistance Usage

Tensile strength

(N/mm

2

)

Yield point

(N/mm

2

)

4 Non-load bearing screws 400 320

5.8 Low resistance screws 500 400

8.8

Medium resistance screws

(cross membe rs, cleat plates,

brackets)

800 640

10.9

High resistance screws

(spring supports, stabilizer

bars and shock absorbers)

1000 900

2.3.2 Characteristics of the material to be used when modifying the chassis

Whe n modi fyi ng the chassis of the vehicle, and in ap p l ica tio ns which reinf or ce the sid e members dir ectl y, the mater i al used must

correspond in quality (Table 2.8) and thickness (Table 2.9) to that of the original chassis.

Should it not be possible to source materials of the thickness indicated, the next superior standard thickness may be used.

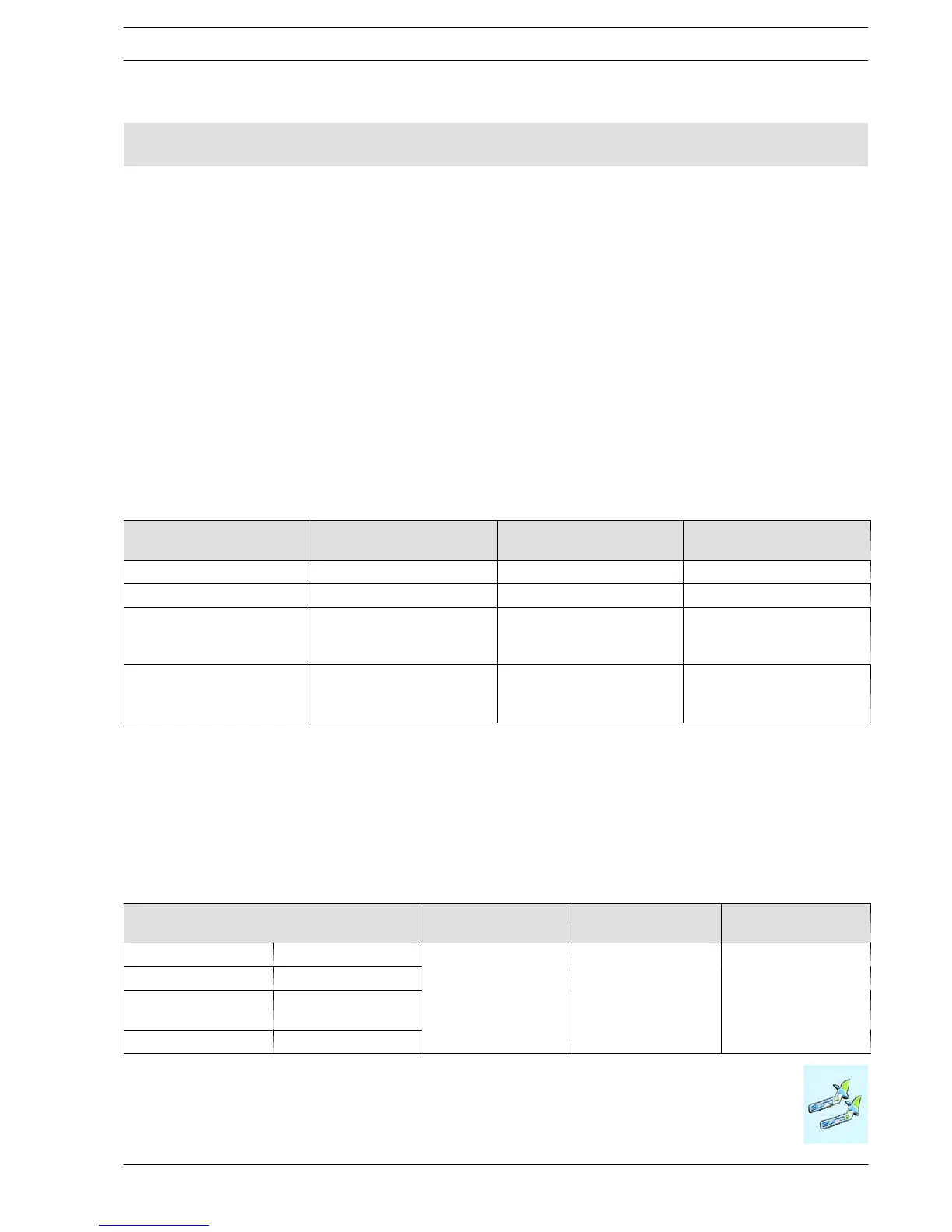

Table 2.8 - Materiale da utilizzare nelle modifiche del telaio Standard IVECO 15-2110 e 15-2812

Steel name

Tensile strength

(N/mm

2

)

Yield point

(N/mm

2

)

A5 elongation

IVECO FEE490

Europe S355J0W

Germany

QSTE500TM -

S355J0W

610 490 23%

UK S355J0W

Loading...

Loading...