2-16

CHASSIS MODIFICATIONS

D

AILY 4x4

Base - May 2007 Print 603.93.761

Drilling the Chassis

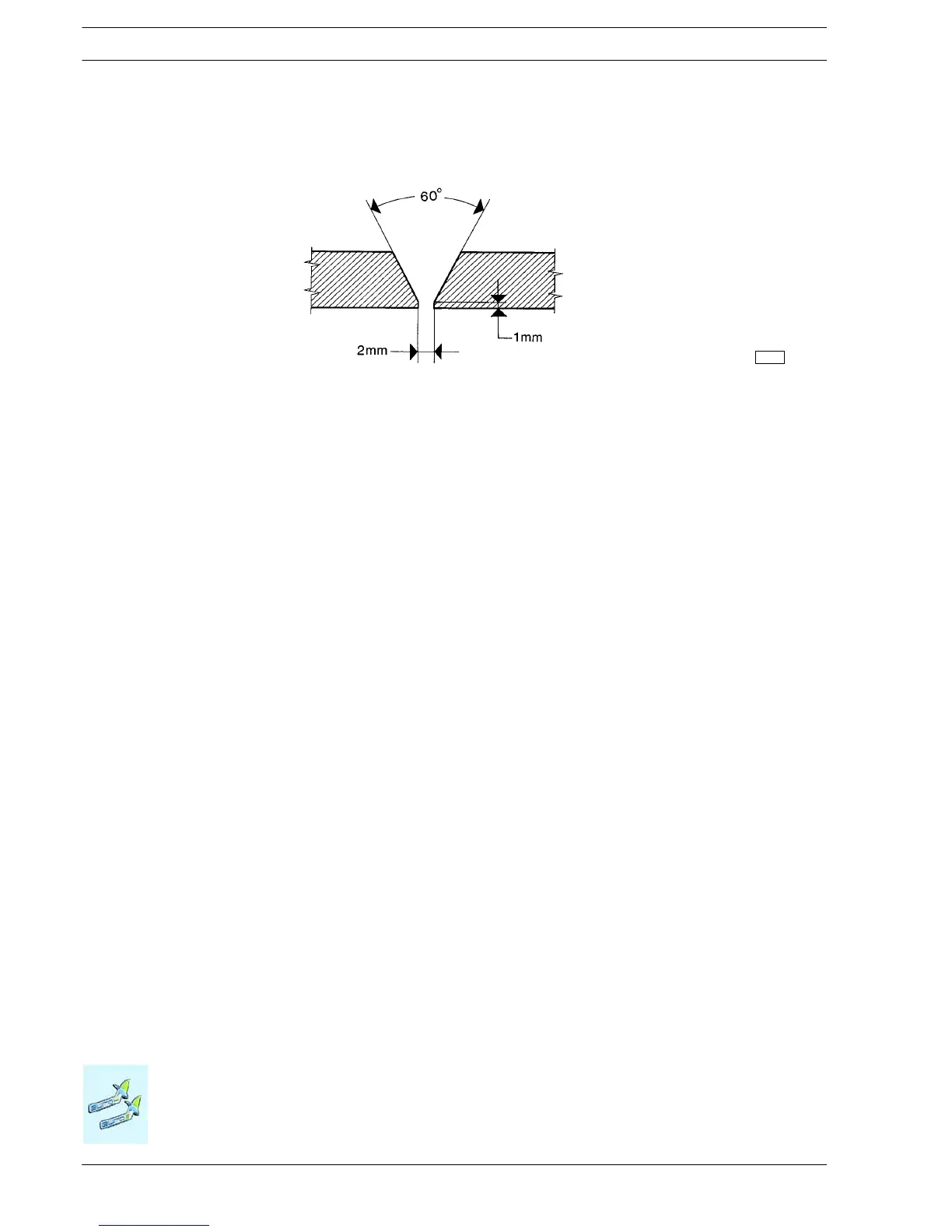

b) O n the i nner side of the side member give the parts that are to be joined a V-sh aped chamfer of 60° along the entire length

to be welded (see Figure 2.3).

91447

Figure 2.3

c) Arc weld in stretches using carefully dried basic electrodes. The recommended electrodes are:

For S 500 MC (FeE490: QSt E 500TM)

Diameter of the electrode is 2.5 mm, c urrent intensity approx. 90A (max. 40A for each millimetre of diameter of the electrode).

Using MIG-MAG welding use a welding rod with the same characteristics as the material to be welded (diameter 1 to 1.2 mm).

Recommended welding rod: DIN 8559 - SG3 M2 5243

gas DIN 32526-M21 or DIN EN 439

If FeE490 is used at very low temperatures, we recommend:

PrEN 440 G7 AWS A 5.28 - ER 80S - Ni 1

gas DIN EN439-M21

Avoid curren t overloading. Welding must be free from marginal cuts and waste material.

d) Repeat the operation on the reverse side by welding as detailed in point c).

e) Allow t h e side members to cool slowly and u n iformly. Cooling by air, water or oth er means is not permitted.

2.3.5 Closing of existing holes

If, when making new holes, the existing holes are found to be too close these may be closed up by welding. To ensure the success

of this operation the outer edge of the hole should be chamfered and copper plate used for the inner part.

For holes with a diameter of over 20 mm, chamfered plugs may be used, welded on both sides.

Loading...

Loading...