2-40

CHASSIS MODIFICATIONS

D

AILY 4x4

Base - May 2007 Print 603.93.761

Changing the Size of the Tyres

2.15.3 Fitting pipes on the vehicle

New pipes must be th oroughly cleaned inside before use (e.g. by blowing throu gh with compressed air).

Pipes shall be secured into their correct positions and the fasteners must fully wrap the pipes: they may be made either of metal,

with rubber/plastic protections, or plastic.

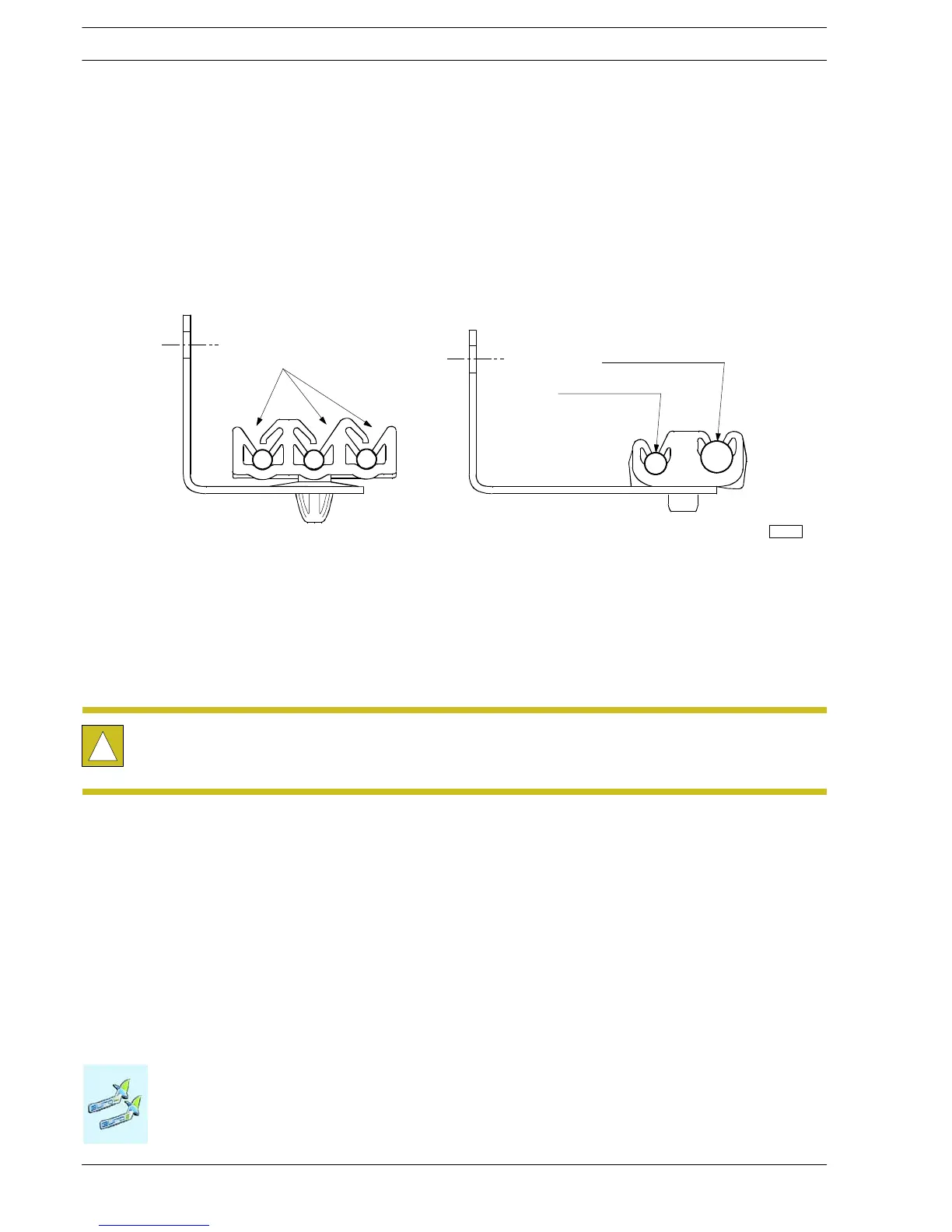

Figure 2.13 illustrates two examples of brackets complete with retaining clips, used to secure the brake pipes along the chassis.

Figure 2.13

102435

3 seats for p ipes (diameter: 4 ÷ 6)

pipe diameter: 7.5 ÷ 8

pipe diameter: 4.8

When a pipe has to pass through the chassis frame (sidemember or cross members), appropriate precautions must be taken

to avoid damage.

Observe adequate distances between the various fixing elements. As a rule the maximum distance of 500 mm should be considered.

For plastic pipes, in order to prevent distortion and t ension on the connectors when fitting them, take the necessary precautions

when arranging the pipe runs and fitting the fixing brackets or clips onto the chassis. Correct fitting of the fixing elements will ensure

that the pipes do not rub against the fixed parts of the chassis.

Observe the necessary safety distances from moving parts and heat sources.

!

Important!

After completing any work either on the system or on the equipment, the air must be bleed from the

system correctly, following the instructions given below. The braking system must then be checked

for correct operation and efficiency.

Loading...

Loading...