CHASSIS MODIFICATIONS

2-29

DAILY 4x4

Print 603.93.761 Base - May 2007

Modifications of the Engine Cooling System

Modifications ofthe Engine Cooling System

2.9 Modifications of the engine air intake and exhaust system

2.9.1 Intake

The specifications of t he engine air intake and exhaust systems must not be altered without authorisation by Iveco. Operations

carried out should not alter the vacuum levels (for the intake) and the original counterpressure levels (for the exhaust).

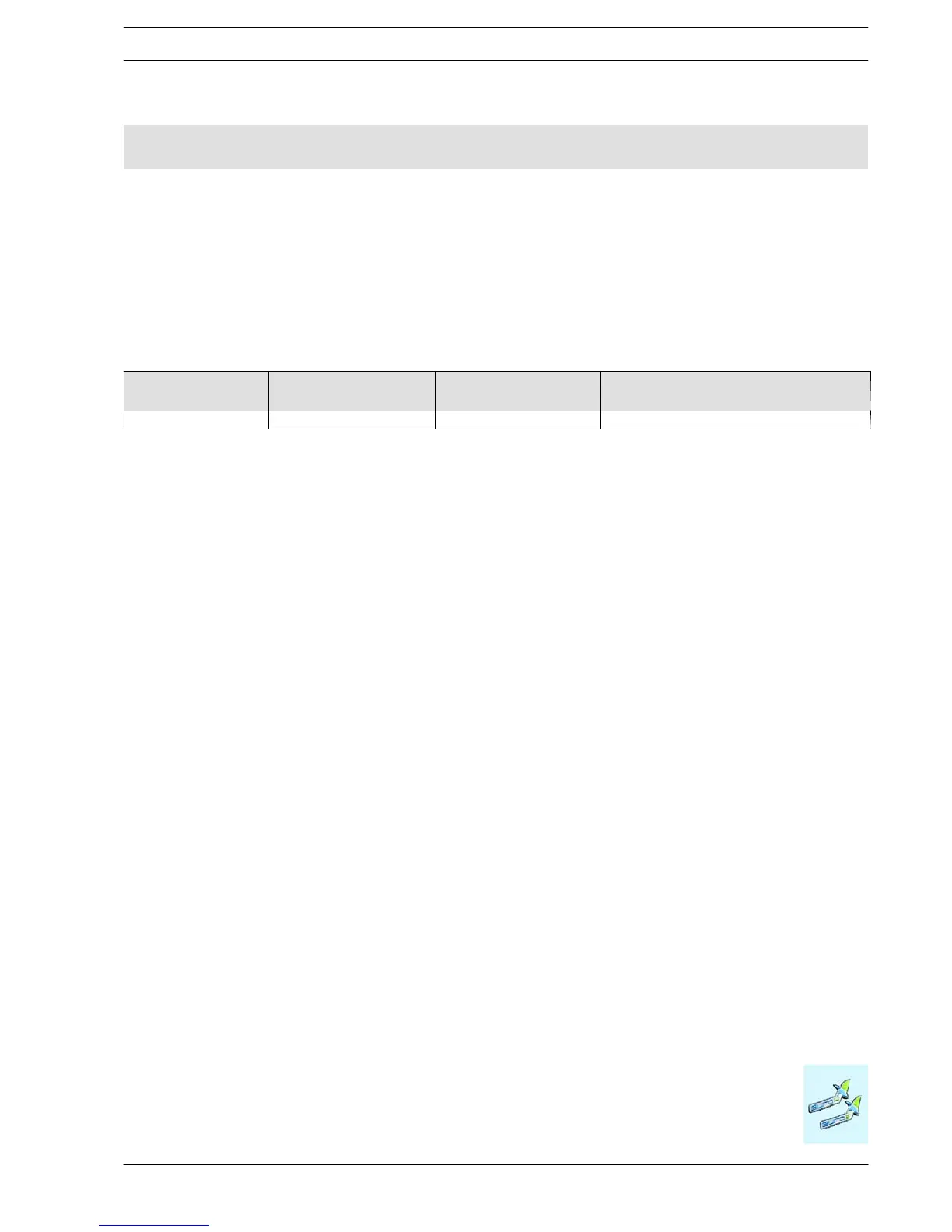

Table 2.15 - Maximum back-pressure permitted at the intake and exhaust, at the rated engine speed and full load

Engines Engine Code

Back-pressure at the

exhaust (kPa)

Minimum/maximum

back-pressure at the intake (kPa)

18 F1CE0481H*C 30 1.6 - 8.5

Any work done on the exhaust sy stem of th e vehicle requires that the vehicle be homologated again w ith regard to noise and smoke

wherever government regulat i ons require it. The air intake must be positioned to avoid the intake of hot air from th e engine and/or

of dusty air or snow and rain. The apertures for the in t ake of air wh ich may have to be made in the bodies of vans, must have a

working surface of not less than two and a half times that of the master hose located upstream of the filter. These apertures (e.g.

openings in the grill) must be of su c h a dimension that they do not become obstructed. It is prohibited to alter the air filer or replace

the origin al filter with a lower air capacity unit. Modifications to the equipment (fuel injection pump, regulator, injectors etc.) are

not permissible as this may alter the correct functioning of the engine and adversely affect the exhaust emissions.

2.9.2 Engine exhaust

Pipes must be laid as straight as possible, bend angles must not exceed 90° and radiuses must be at least 2.5 times the outer

diameter. Avoid constrictions and use effective cross-sections no smaller t h an the originals. Leave a big enough gap between the

exhaust piping and the electric system, plastic piping, spare wheel (minimum 150 mm), plastic fuel tank (minimum 100 mm), etc.

Lower values (e.g. 80 mm) may be approved if steel guard panels are used. Further reductions require the use of heat insulation

or the replacement of plastic pipes with steel pipes. Modifications to the silencer body are not permitted and neither is it permitted

to make changes to equipment (injection pump, regulator, injecto rs, etc.) that co uld impair efficient engine operation and affect ex-

haust gas emissions.

Loading...

Loading...