CHASSIS MODIFICATIONS

2-21

DAILY 4x4

Print 603.93.761 Base - May 2007

Modifying the Rear Overhang

Towed vehicle equipped with a towin g device th at c an not move in a vertical direction (in relation to the t railer) and in which

the axle or axles are arranged about the vehicle centre of gravity (under uniform load) so that only a small vertical load no greater

than 10% of the maximum trailer load or than 1000 kg, if low er, is t ransmitted to the vehicle (low er value applies).

Mid- axled trailers are t herefore subgroups of trailers with rigid drawbars.

116774

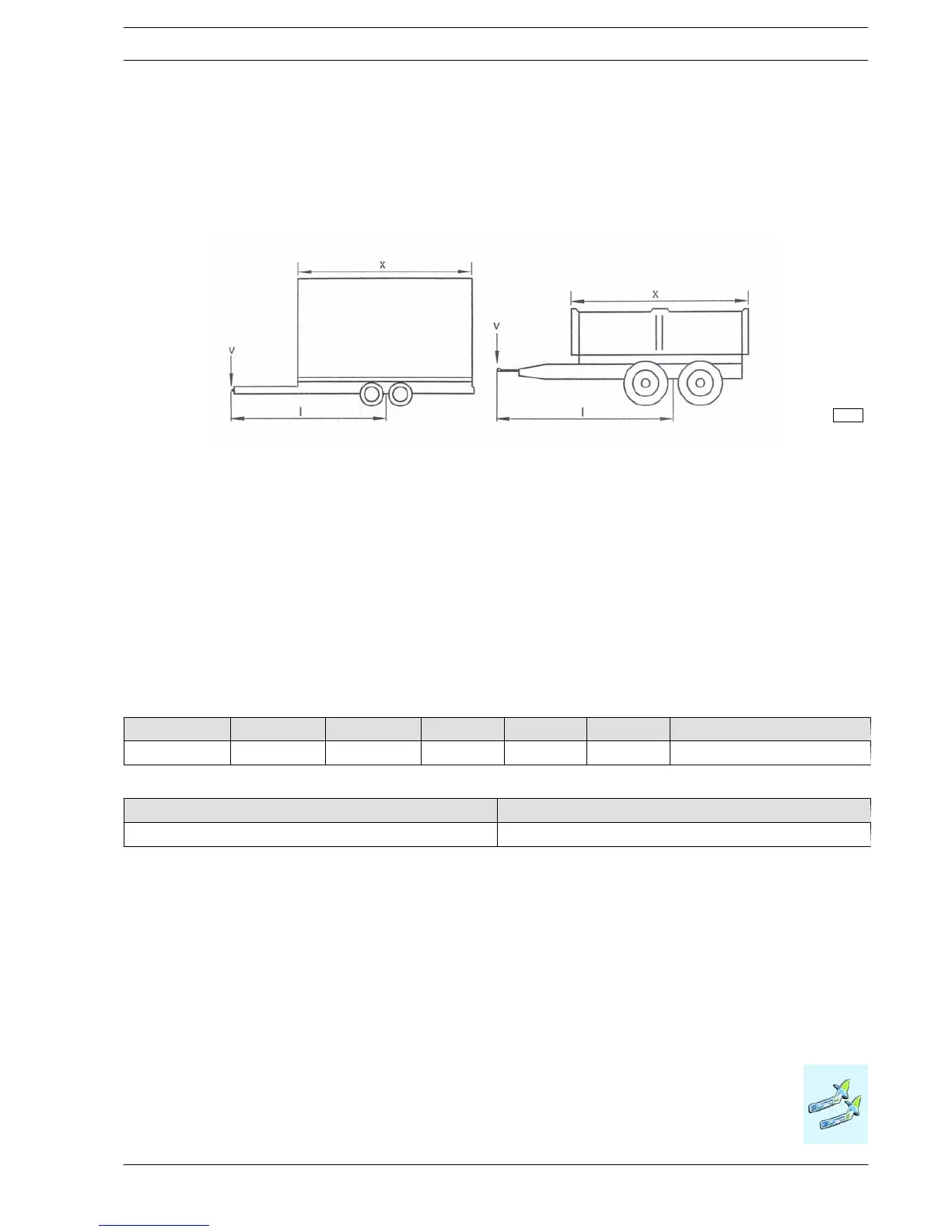

Figure 2.5

Length of trailer work surface and theoretical length of crossbar

The use of trailers with cent re axles (rigid tow bar trailers with single or tandem axles), with respect to articulated tow bar trailers,

entails an increase in bending stress on the rear chassis overhang as well as an increased torsional stress of the rear towing c ross

member resulting from the vertical static and dynamic loads which the tow bar exerts on the hook (for example when braking or

on bumpy roads).

On vehicles for which towing of a trailer is permitted and in acco rdance with values laid down by IVECO for each model, towable

weights w ith mid-axled trailers and vertical loads on the drawbar may be defined on the basis of the size of the drilling flange present

on the vehicle rear beam (see Table 2.11).

With long rear overhangs, it may be necessary to adopt larger subframe sections than normal depending on the towable weights.

Table 2.11 - Approved towing hooks available

Maker Type Class D(kN) D

c

(kN) V(kN) EC approval no.

Pommier 70- C/3 S 31 31 37.5 e 2*94/20*0062*00

The followin g table sh o ws S maximum admitted value for original towing cross member when towing a central axle trailer.

Model Maximum S (kN)

35S18W - 55S18W 100

Loading...

Loading...