123

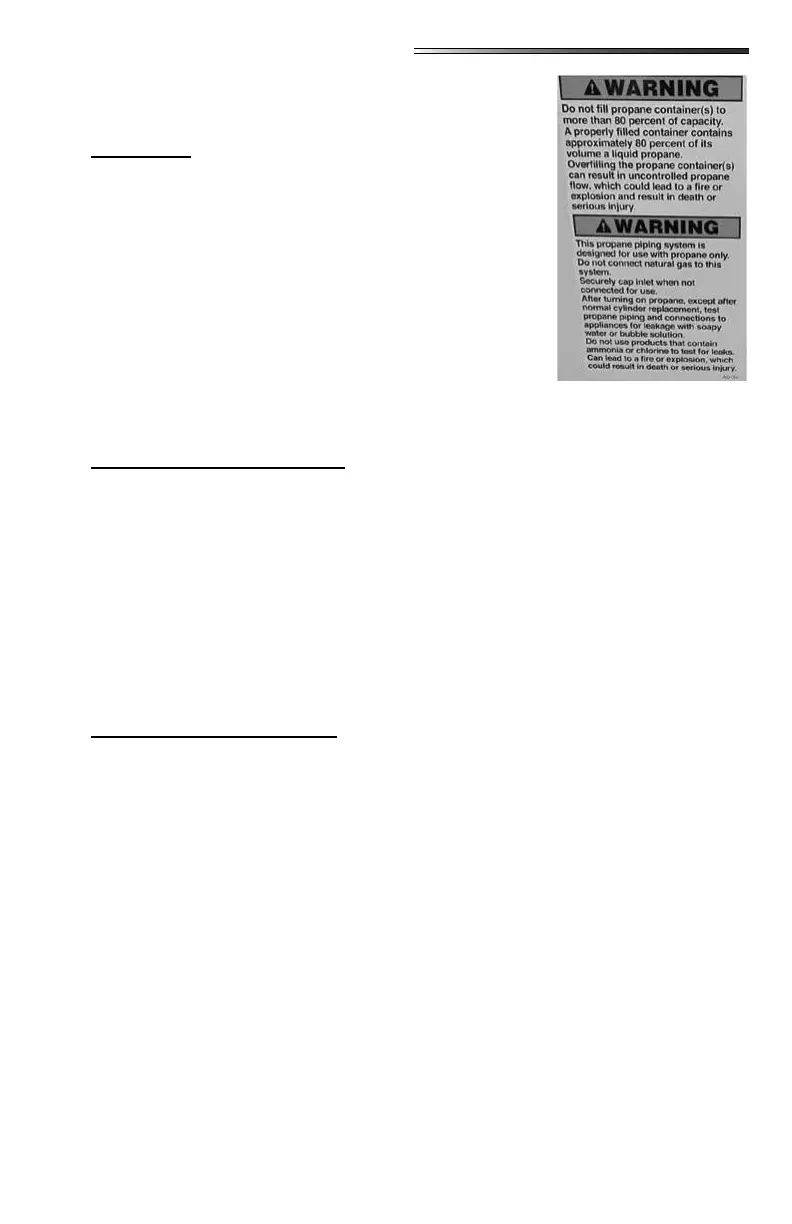

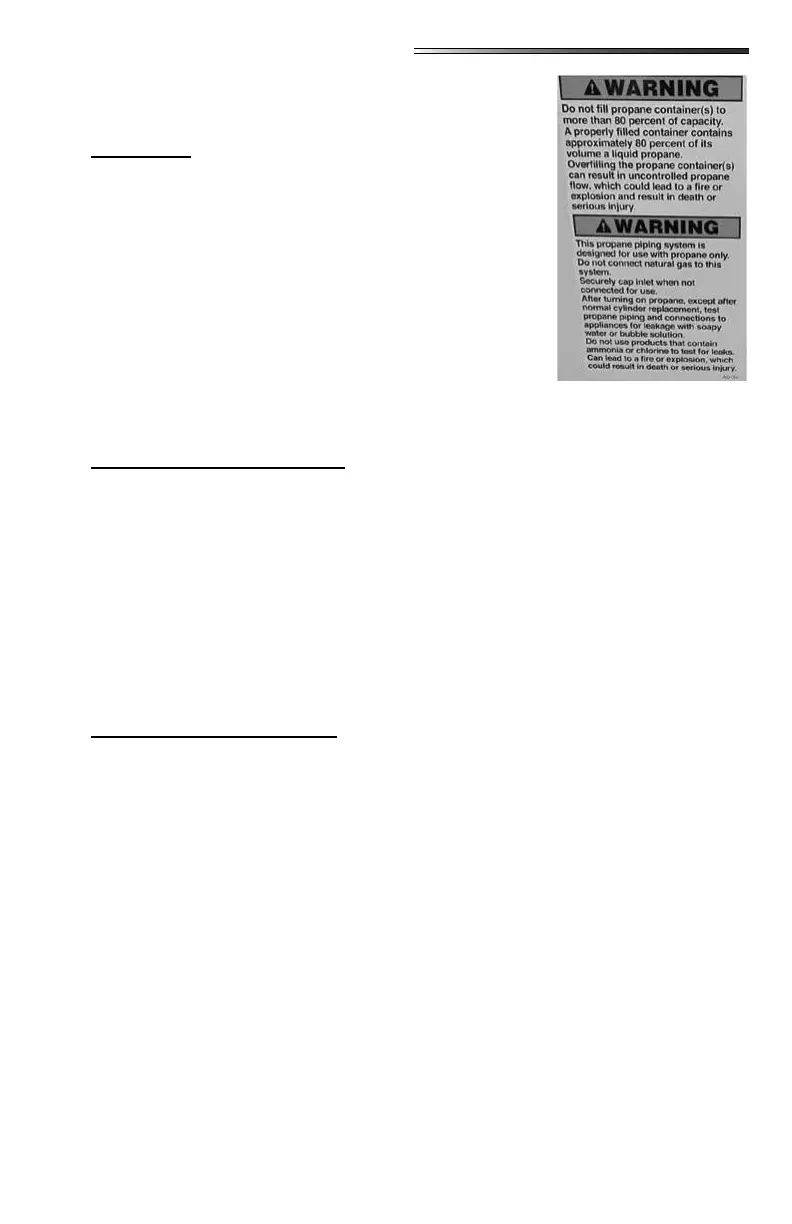

This label should be kept permanently axed to your RV.

Refer to your Warranty Packet for more information on the LP

gas system components.

Propane gas is normally non-corrosive - you need not worry

about the inside of your container. However, the outside should

be kept free from rust by a periodic coat of paint in a light reec-

tive color. Rust, scratches and/or dents can aect the safety of

the cylinder. Inspect the cylinder at regular intervals.

Ifs a problem, have it evaluated by a qualied technician and

discard it. DOT requires that a visual inspection be made prior

to each lling.

Any cylinder that has been exposed to re, leaks or seems dam-

aged should not be relled.

Do not attempt to repair any containers, container valves, regu-

lator or appliances by yourself. Use only trained certied propane gas

service technicians to perform repairs.

DOT cylinders may only be used for 12 years after their manufacture

date (the number of years for certication may vary in your area). After that, the cylinders

must be “recertied” which provides another ve years of use.

The cylinders can be recertied every ve years thereafter. Federal DOT (Department of

Transportation) regulations require periodic inspections and re-qualications of the propane

cylinders. DO NOT USE damaged or rusted containers.

Verify with your local propane dealer that all required inspections and certications have

been completed on the propane cylinder within the correct time period before relling the

cylinder. Have the LP system checked for leakage each time a cylinder is relled or after

any part of the propane system has been disconnected.

The hoses, pipes, tubes and ttings used in your propane system are designed to withstand

pressures exceeding those of the propane system. However, because environment and time

can both contribute to the deterioration of these components, they must be inspected for

wear at regular intervals.

Be sure to inspect the hose before each season and when having the tank relled. Look for

signs of deterioration such as cracks or loss of exibility. When replacing the hose or other

propane components, make sure to always replace them with components of the same type

and rating (check with your dealer).

Fittings are used to connect the various system components to each other. The P.O.L. tting

at the end of the propane supply hose is made of brass so that pipe sealants are not necessary

to prevent leaking.

It also has a left-handed thread, which means that it is turned clockwise to remove, and

counter-clockwise to tighten. The P.O.L. tting has been designed to help restrict the ow

of LP gas in the event of a regulator failure or hose malfunction.

Loading...

Loading...