FORM 160.54-O1

ISSUE DATE: 9/10/2014

JOHNSON CONTROLS

134

SECTION 2 - OPTIVIEW CONTROL CENTER INTRODUCTION

This setpoint allows for either standard or higher tem-

perature condenser temperature operation. It is set at the

factory and requires an ADMIN password to change it.

It is only visible when set to Extended. It is set to Ex-

tended for those chillers equipped for high condenser

temperature operation. Otherwise, it is set to Standard.

When Heat Pump Duty is set to Enabled, this setpoint is

automatically set to Extended. For R134a chillers, refer

to Table 3 on Page 134.

PRV Position

(Software version C.OPT.01.21.307 and later)

Access Level Required: SERVICE

New production chillers after June 2009 can be

equipped with an optional Pre-rotation Vanes Potenti-

ometer, regardless of other options. This setpoint al-

lows the software to be used in all YK chillers, whether

equipped with the potentiometer or not. The PRV po-

sition will be shown on respective screens when En-

abled.

• Enabled – Automatically set to this setting if Hot

Gas Bypass or Variable Geometry Diffuser (VGD)

is enabled on the OPERATIONS Screen or Motor

Drive Type Setpoint is set to VSD or MVVSD.

The actual connection point of the potentiometer

is determined by the equipment conguration:

If equipped with a VSD in YORK protocol con-

guration, itis connected to theACC Board; in

Modbus Protocol Conguration, it is connected

to the Microboard J7. If not equipped with VSD,

but equipped with Hot Gas Bypass, the connec-

tion point is determined by which I/O Board is

present: with I/O Board 371-02514-000, it is con-

nected to this board; otherwise, it is connected to

the Microboard J7. If not equipped with Hot Gas

Bypass but equipped with a VGD, it is connected

to the Microboard J7.

• Disabled – Set to this position when not equipped

with a PRV potentiometer. If equipped with a VSD,

MVVSD or the Hot Gas Bypass, or Variable Ge-

ometry Diffuser is enabled; this setpoint is auto-

matically enabled and cannot be set to disabled.

Motor Monitoring

(Software version C.OPT.01.22.307 and later)

Access Level Required: SERVICE

Allows the Service Technician to enable or disable the

Motor Monitoring feature.

Heat Recovery

(Software version C.OPT.01.21.307 and later)

Access Level Required: SERVICE

Allows the Service Technician to enable or disable the

Heat Recovery feature.

Heat Recovery cannot be used simultaneously with

Heat Pump Duty. When Heat Pump Duty is enabled,

Heat Recovery is automatically disabled and locked.

Head Pressure Control

(Software version C.OPT.01.21.307 and later)

Access Level Required: SERVICE

Allows the Service Technician to enable or disable the

Head Pressure Control feature.

Head Pressure Control cannot be used simultaneously

with Heat Pump Duty. When Heat Pump Duty is en-

abled, Head Pressure Control is automatically disabled

and locked.

Heat Pump Duty

(Software Version C.OPT.01.23.307 and later)

Access Level Required: ADMIN

Allows the Service Technician to enable and disable the

Heat Pump feature. The access level must be ADMIN

and the Refrigerant Type must be set to R-134a (SW1-

1) for the setpoint to appear on this screen. When Heat

Pump Duty is enabled, Heat Recovery and Head Pres-

sure Control are automatically disabled and locked.

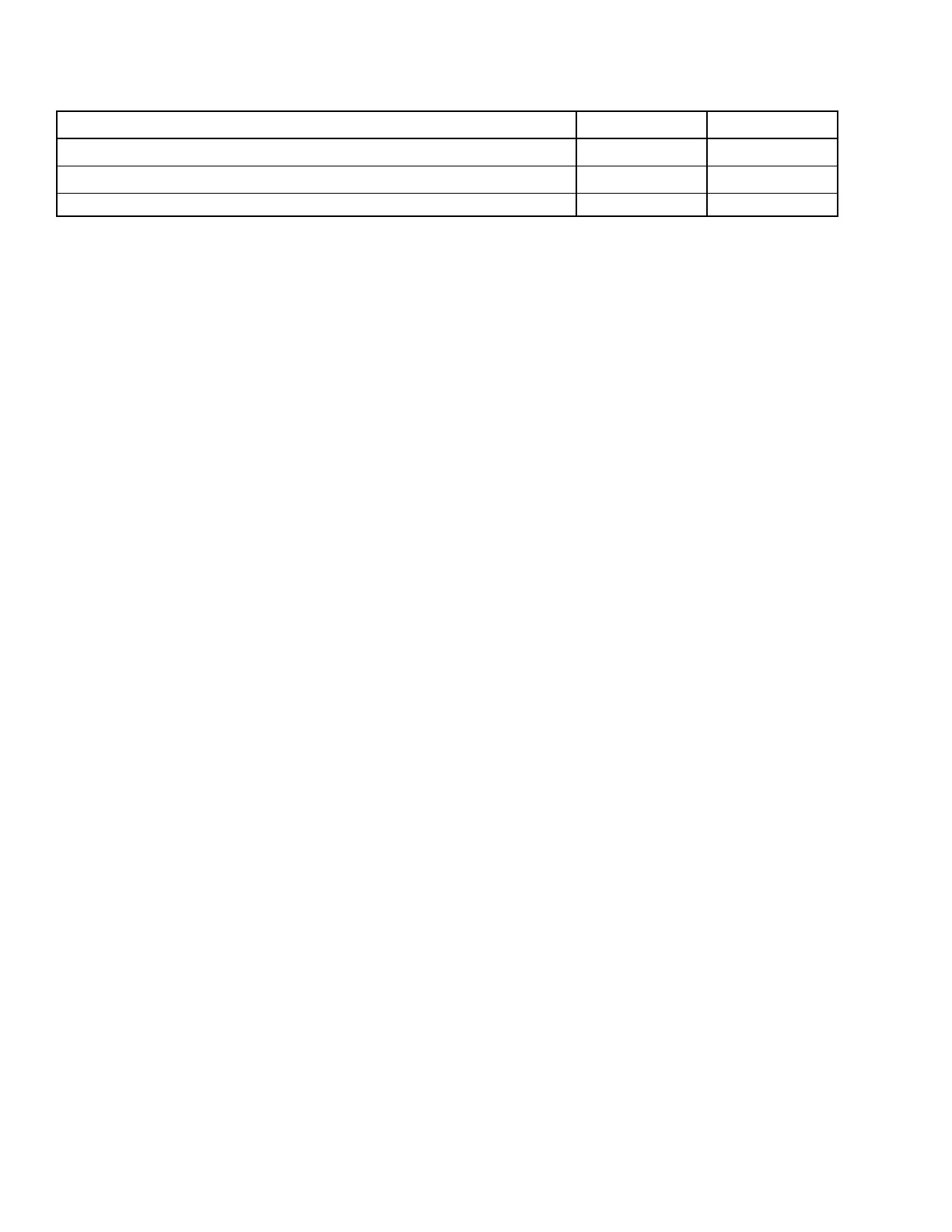

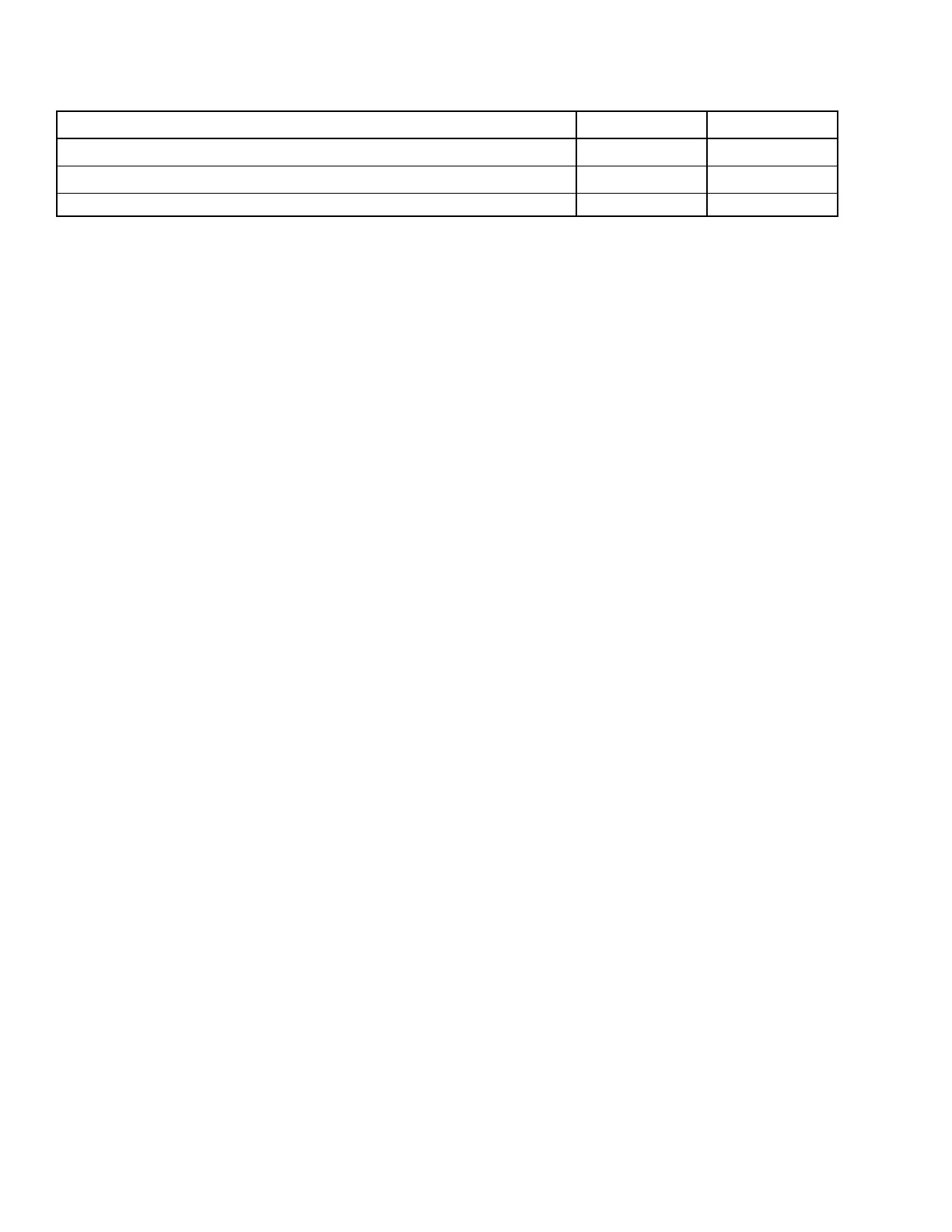

TABLE 3 - CONDENSER TEMPERATURE RANGE

STANDARD EXTENDED

Warning – High Pressure Limit – Maximum allowable value (PSIG) 162.5 193

Condenser – High Pressure – Trip/reset threshold (PSIG) 180/120 200/140

Condenser – High Pressure Stopped – Trip/reset threshold (PSIG) 160/160 170/170

Loading...

Loading...