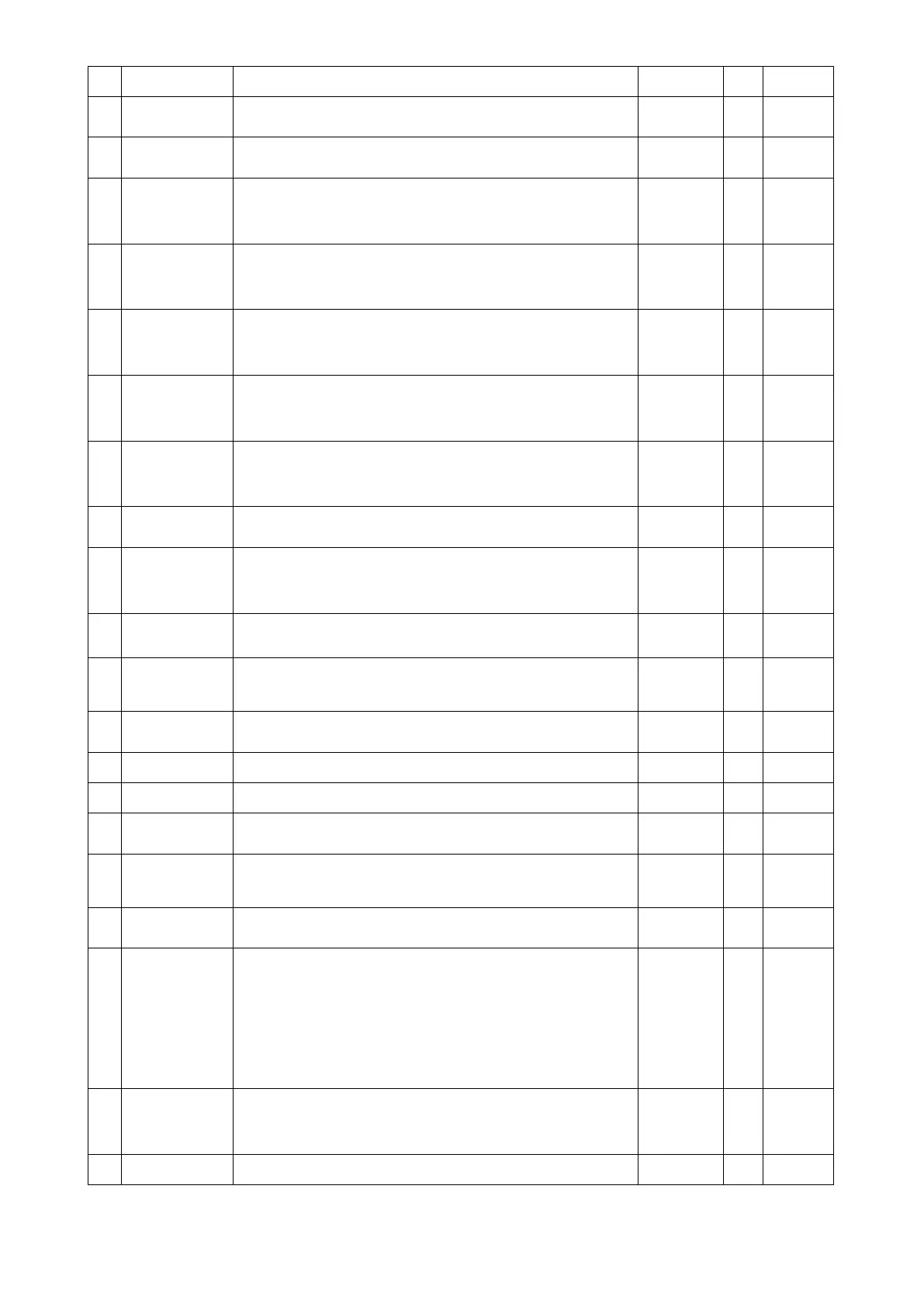

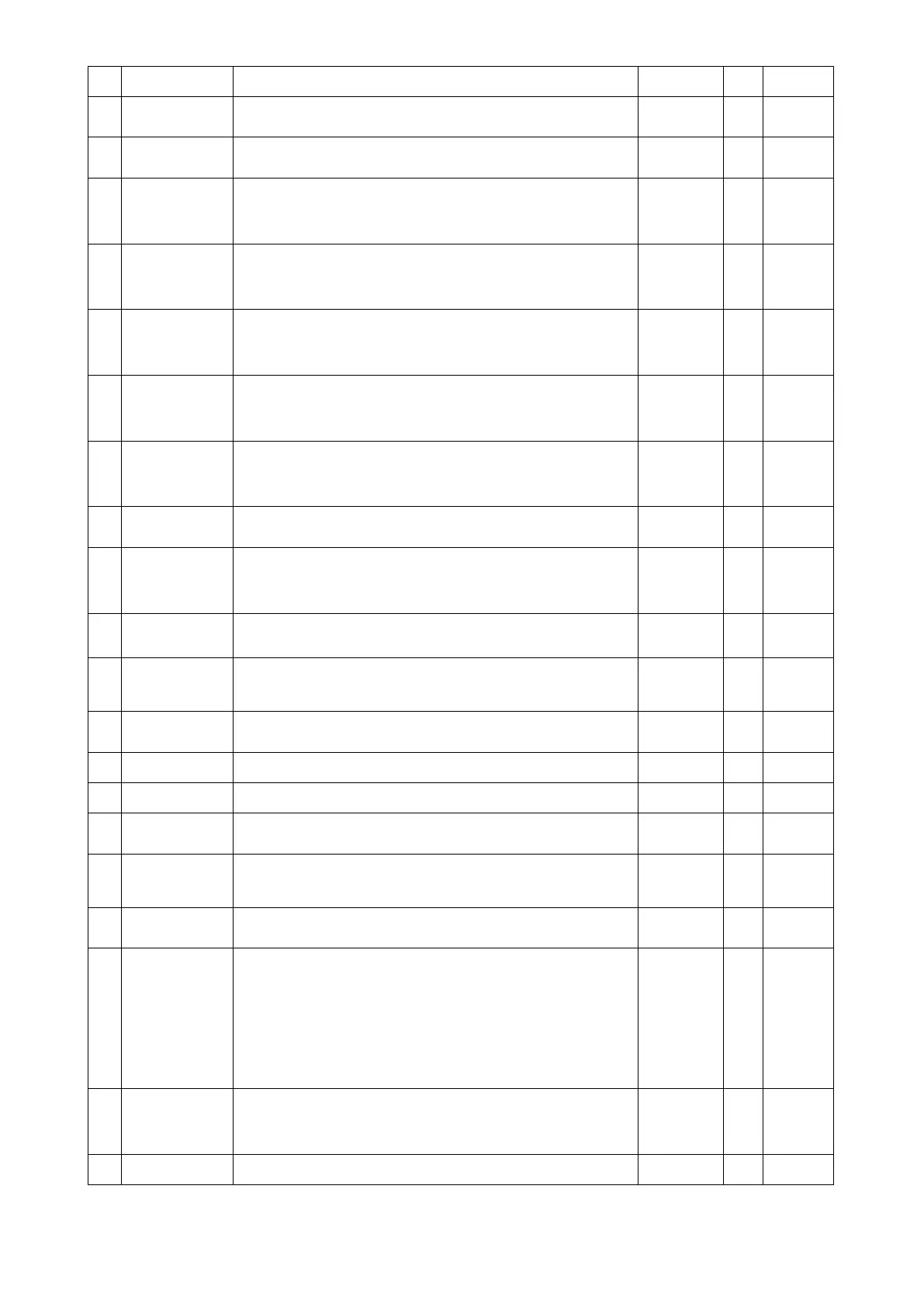

– 90 –

No. Item Description Setting range

Setting

levle

Default

P23 Position to lift the

presser foot by

pedal

The position to lift the presser foot by operating the pedal is set with this

function setting item.

30 to 1000

(–)

S 270

P24 Position to perform

thread trimming by

pedal

The position to perform thread trimming by operating the pedal is set with this

function setting item.

30 to 500

(–)

S 130

*

P25 Correction of

solenoid-on timing

for the reverse feed

stitching at the end

of sewing

Stitch alignment can be carried out by changing the timing of actuating the

reverse-feed stitching solenoid at the time of reverse feed stitching at the end

of sewing. When the set value for this parameter is increased, the length of

stitch at the beginning of C process is increased.

0 to 200

(°)

U 123

* P26

Correction of

solenoid-off timing

for the reverse feed

stitching at the end

of sewing

Stitch alignment can be carried out by changing the timing of releasing the

reverse-feed stitching solenoid at the time of reverse feed stitching at the

end of sewing. When the set value for this parameter is increased, the length

of stitch at the end of C process is decreased and the length of stitch at the

beginning of D process is increased.

0 to 200

(°)

U 130

P29

Brake force of the

main shaft at the

time of stopping the

sewing machine

after thread trimming

Main shaft brake force is adjusted with this function setting item for preventing

the sewing machine from overrunning before stopping.

If it is too large, it takes to much time to stop, and if it is too small, overrunning

may occur.

1 to 45

(–)

S 30

* P32

Correction of

solenoid-on timing

for the overlapped

stitching

Stitch alignment can be carried out by changing the timing of actuating the

reverse feed stitching solenoid at the time of overlapped stitching. When the

set value for this parameter is increased, the length of stitch at the end of A (C)

process is increased and the length of stitch at the beginning of B process is

decreased.

0 to 200

(°)

U

MS : 105

SH : 92

* P33

Correction of

solenoid-off timing

for the overlapped

stitching

Stitch alignment can be carried out by changing the timing of releasing the

reverse-feed stitching solenoid at the time of overlapped stitching. When the

set value for this parameter is increased, the length of stitch at the end of B

process is increased and the length of stitch at the beginning of C process is

decreased.

0 to 200

(°)

U

MS : 105

SH : 100

* P37

First current value

(ON duty) of thread

clamp

The rst current value (ON duty) for the thread clamp is set with this function

setting item.

Current value from activation of the thread presser at (P78) to (P166) passage

0 to 100

(%)

U

MS : 40

SH : 50

P44

Brake force of the

main shaft at the

time of stopping the

sewing machine on

the way

Main shaft brake force is adjusted with this function setting item for preventing

the sewing machine from overrunning before stopping on the way.

1 to 45 S 16

*

P45 Setting of BT holding

Duty

Sets the current value of the solenoid at BT on.

1 to 50

(%)

S 30

* P46

Setting of the

function of reverse

revolution to lift the

needle

This function rotates the main shaft in the reverse direction of sewing to bring

the needle bar to the highest position.

ON : Reverse-revolution operation is in the ON state

OFF :

Reverse-revolution operation is in the OFF state

ON/OFF U OFF

P47

Reverse revolution

angle to lift the

needle

The operating angle of the reverse-revolution to lift the needle is

adjusted with this function setting item.

50 to 200

(1/4°)

S 160

P48

Sewing speed at a

low speed

The minimum sewing speed of the sewing machine by operating the pedal is

set with this function setting item.

100 to 500

(sti/min)

U 200

P49

Sewing speed for

thread trimming

Sewing speed to be used when performing thread trimming is set with this

function setting item.

100 to 500

(sti/min)

U 210

P50 2nd thread trimming

speed

0: Operation is conducted at the rst thread trimming speed.

10 to 500: The speed in the latter half is set when the thread trimming

speed is decreased in the latter half.

0 to 500

(sti/min)

S 180

P51

Timing to change

over to the 2nd

thread trimming

speed

The timing to change over the sewing speed to the 2nd thread trimming

speed is set with this function setting item. 270 to 370

(°)

S 320

P52

Time to wait for

sewing after lowering

the presser foot

The time to wait for starting sewing after the presser foot is lowered is set.

10 to 500

(ms)

S 120

P53 Setting of operation

of the presser foot

when the back

part of pedal is

depressed

The operation of the presser foot when the back part of pedal is depressed is

set with this function setting item.

0 : Presser foot does not operate even when the back part of pedal is

depressed.

1 : Presser foot goes up to the 1st presser-foot lifting position when the

back part of pedal is depressed by half of the depth. It goes up to the

2nd presser-foot lifting position when the back part of the pedal is

further depressed.

2 : Presser foot does not operate even when the back part of pedal is

depressed. It goes up to the 2nd presser-foot lifting position when the

back part of the pedal is further depressed.

0 to 2

(–)

U 1

P66 Setting of the

machine head tilt

switch

The machine head tilt detection method of the machine head tilt switch is set

with this function setting item.

0 :

Not detected

1 :

Error is detected in the case the signal is LOW

2 :

Error is detected in the case the signal is HIGH

0 to 2

(–)

S 1

*

P68 Maximum sewing

speed

The maximum sewing speed is set with this function setting item. (The MAX

value differs with the type of machine head. MS: 5000; SH: 4500)

100 to MAX

(sti/min)

S

MS : 4000

SH : 3500

*

Supplementary explanation is added in 4.-(2) Further information about memory switch.

◎

These data are stored in the main board in the control box. Data other than these data are stored in the panel board in the panel.

Loading...

Loading...