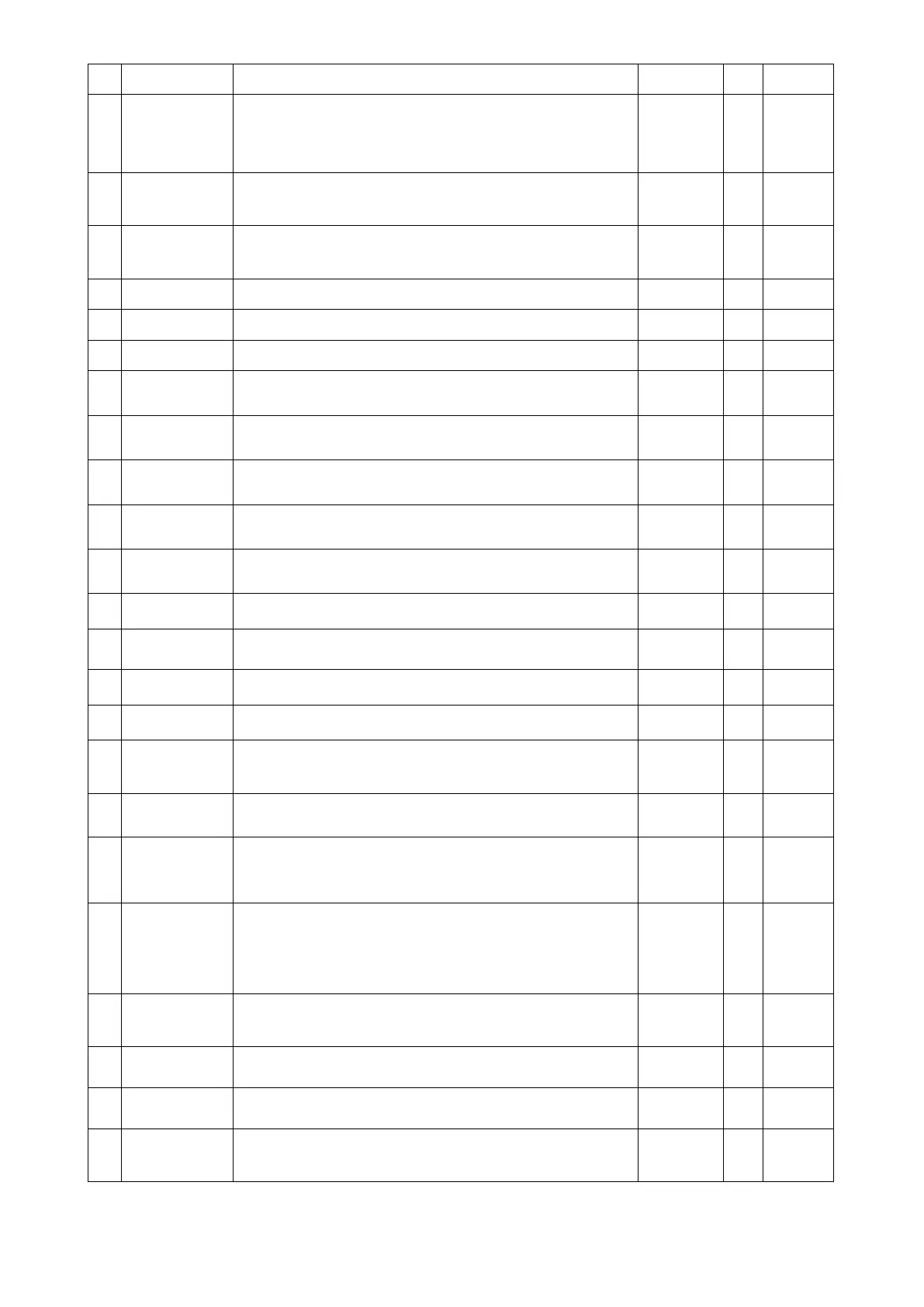

– 91 –

No. Item Description Setting range

Setting

levle

Default

P70 Machine head

selection

(Initialization of data)

Machine head type is selected with this function setting item.

2 : DDL-8000APMS

3 :

DDL-8000APSH

★

Select an applicable head and press the enter switch, and all the P

and J data except "P72", "P73", "P123" and "J14" are initialized. The

data of N are out of the initialization target.

2 to 3

(–)

S 2

◎

P72 Adjustment mode for

the needle-up stop

angle

The principal axis angle at that moment is always shown on the display.

Rotate the pulley to adjust the needle top position and press the enter switch,

and the needle top angle and needle bottom angle are automatically adjusted.

★

This data is not initialized with P70.

0 to 1439

(1/4°)

S 0

◎

P73 Adjustment mode

for the needle-down

stop angle

The principal axis angle at that moment is always shown on the display.

Rotate the pulley to adjust the needle bottom position and press the enter

switch, and only the needle bottom angle is automatically adjusted.

★

This data is not initialized with P70.

0 to 1439

(1/4°)

S 0

*

P74 Buffer brake waiting

time at BT off

Time from shutoff of the REVERSE signal for impact absorbing to solenoid

restart (to brake application)

0 to 990

(ms)

S 13

*

P75 Buffer brake time at

BT off

Time of restarting the solenoid for impact absorbing (of brake application)

0 to 990

(ms)

S 10

*

P76 BT suction time Time when the BT solenoid is activated

10 to 990

(ms)

S 200

*

P77 Back-tack solenoid

ON timing at the end

of sewing

The BT solenoid ON timing at the end of sewing is set with this function

setting item.

★

This parameter applies only to the free stitching.

50 to 330

(°)

U 150

P78 Thread clamp ON

angle

ON-angle of the thread clamp is set with this function setting item.

0 to 359

(°)

U 190

P79 Thread clamp OFF

angle

OFF-angle of the thread clamp is set with this function setting item.

0 to 359

(°)

U 300

P87 Wiper operating time The time during which the wiper is turned ON is set with this function setting

item.

10 to 990

(ms)

S 50

P93 Reaction time when

the back part of

pedal is depressed

The reaction time required to start lifting of the presser foot after the back part

of the pedal is depressed is set with this function setting item.

10 to 990

(ms)

S 100

P109 Wiper operation

timing

The waiting time required until the wiper starts operation after the sewing

machine stops with its needle up.

5 to 990

(ms)

S 5

P110 Waiting time until

the sewing machine

starts next sewing

The waiting time required until the sewing machine starts next sewing after

the thread trimming solenoid is turned OFF.

0 to 500

(ms)

S 250

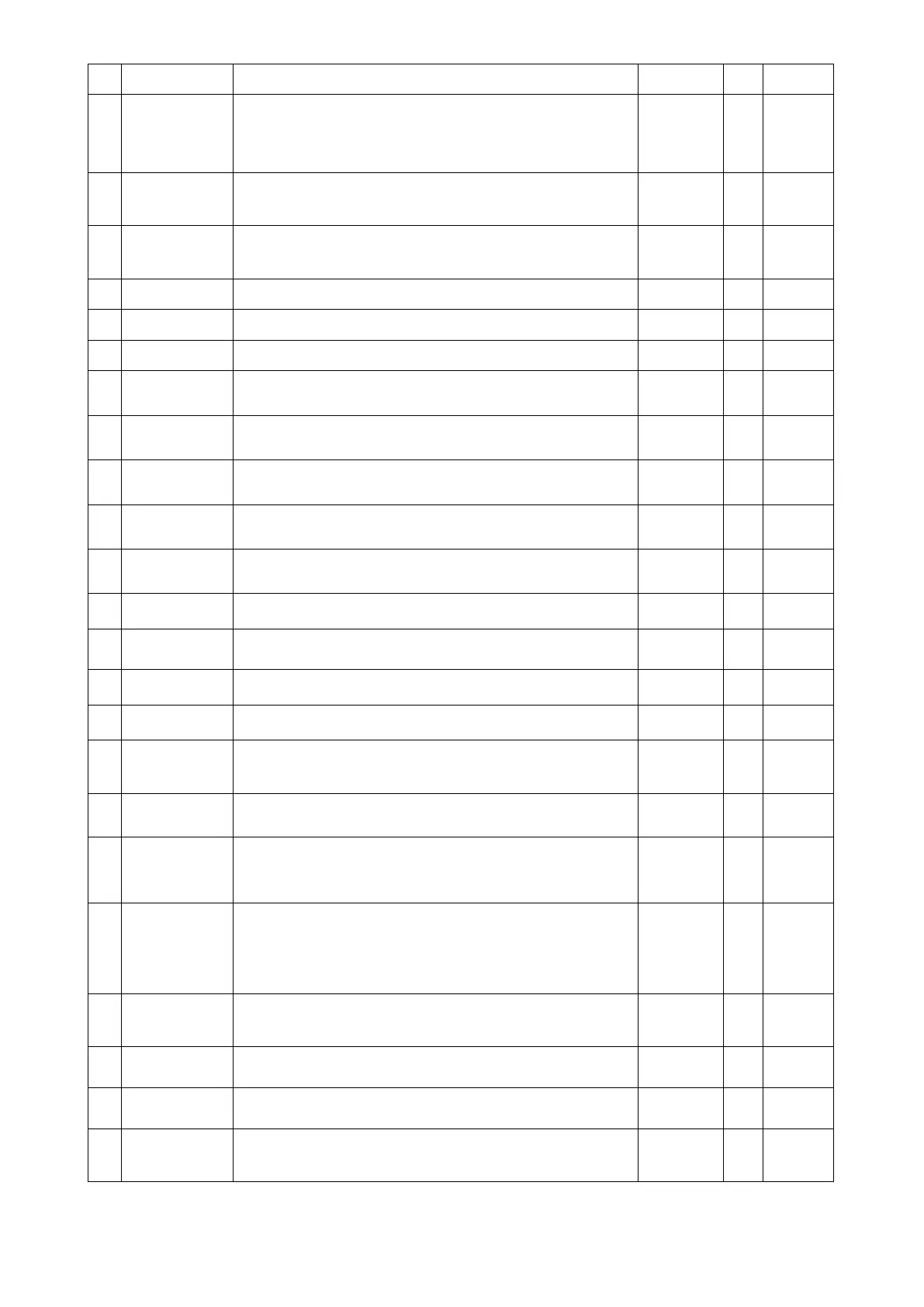

P112 Needle-up stop

angle

The angle from the upper dead point of needle to the needle-up stop position

is set with this function setting item.

-359 to 359

(°)

S 55

P113 Bobbin counter The largest value that the bobbin counter can count is set with this function

setting item. When the counter reaches that value, it stops counting.

0 to 9999

(10 stitches)

U 500

P114 Reverse feed

solenoid operation

stopping angle

(start)

The angle at which the solenoid output is prohibited (start) after pressing the

reverse-feed stitching on the way switch. 0 to 359

(°)

S 262

P115 Reverse feed

solenoid operation

stopping angle (end)

The angle at which the solenoid output is prohibited (end) after pressing the

reverse-feed stitching on the way switch.

0 to 359

(°)

S 112

P116 Function of

prohibiting the

correction operation

after turning the

handwheel by hand

The correction stitching function when turning the pulley by hand upon

completion of the polygonal-shape stitching is set with this function setting

item.

0 :

Correction sewing function is enabled

1 :

Correction sewing function is disabled

0 to 1

(–)

U 0

P117 Thread trimming

operation after

turning the

handwheel by hand

The thread trimming operation after turning the pulley by hand to move the

sewing machine from the upper and lower positions is set with this function

setting item.

0 : Thread trimming operation is carried out after turning the pulley by

hand.

1 : Thread trimming operation is not carried out after turning the pulley by

hand.

0 to 1

(–)

U 1

*

P118 Setting of the needle

up/ down switch

operation after

thread trimming

The operation of the needle up/down switch after thread trimming is set with

this function setting item.

0 :

Needle up/down operation is carried out

1 :

One-stitch operation is carried out

0 to 1

(–)

U 0

P126 Electric current while

the presser motor is

at rest

The electric current while the presser motor is in the stopping state is set with

this function setting item.

(For setting value 2, the value becomes 2 x 0.5 A = 1.0 A.)

1 to 12

(1/2A)

S 2

P127 Electric current while

the presser motor is

in operation

The electric current while the presser motor is in the operating state is set

with this function setting item.

(For setting value 2, the value becomes 2 x 0.5 A = 1.0 A.)

1 to 12

(1/2A)

S

MS : 8

SH : 12

P128 Number of

condensation

stitches at the

beginning of sewing

The number of condensation stitches at the beginning of sewing is set with

this function setting item. 0 to 5

(stitches)

U 0

*

Supplementary explanation is added in 4.-(2) Further information about memory switch.

◎

These data are stored in the main board in the control box. Data other than these data are stored in the panel board in the panel.

Loading...

Loading...