– 128 –

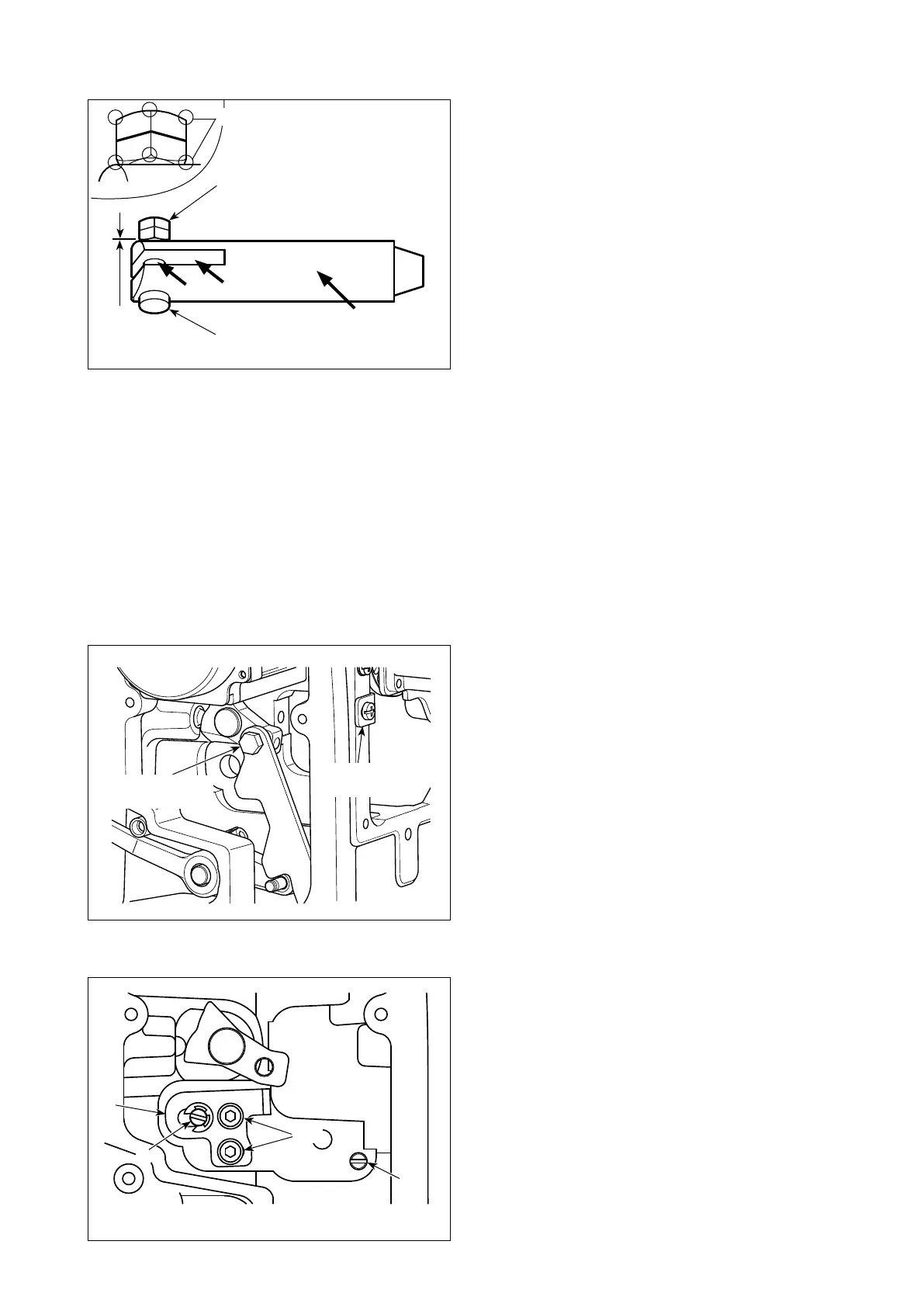

❼

❻

0.5mm

C

BA

Place the chamfered section

outside

Feed adjustment

pin

Motor cable

guide

⓰

⓮⓯

⓫

⓬

④

Subassembling the solenoid plunger pin

1)ApplyJUKIGreaseAtotheshaft sectionA of

plunger pin

❻

.

2) Holding the plunger while turning its forked

section to the left and its notch upward, pass

plunger pin

❻

from this side to the far side

accordingtotheorientationshowninthegure.

3)Tightenrstnut

❼

sothataclearanceof0.5mm

is provided between the plunger and nut

❼

.

4)Securingrstnut

❼

with a spanner so that it will

not move, tighten second nut

❼

.

[Tighteningtorque:4.4-5.5N·m(45–55kgf·cm)]

(Caution) Assemble nuts

❼

while turning their

chamfered sections outside.

5)ApplyJUKIGreaseAtotheforkedsectionBandperipheryCoftheplunger.

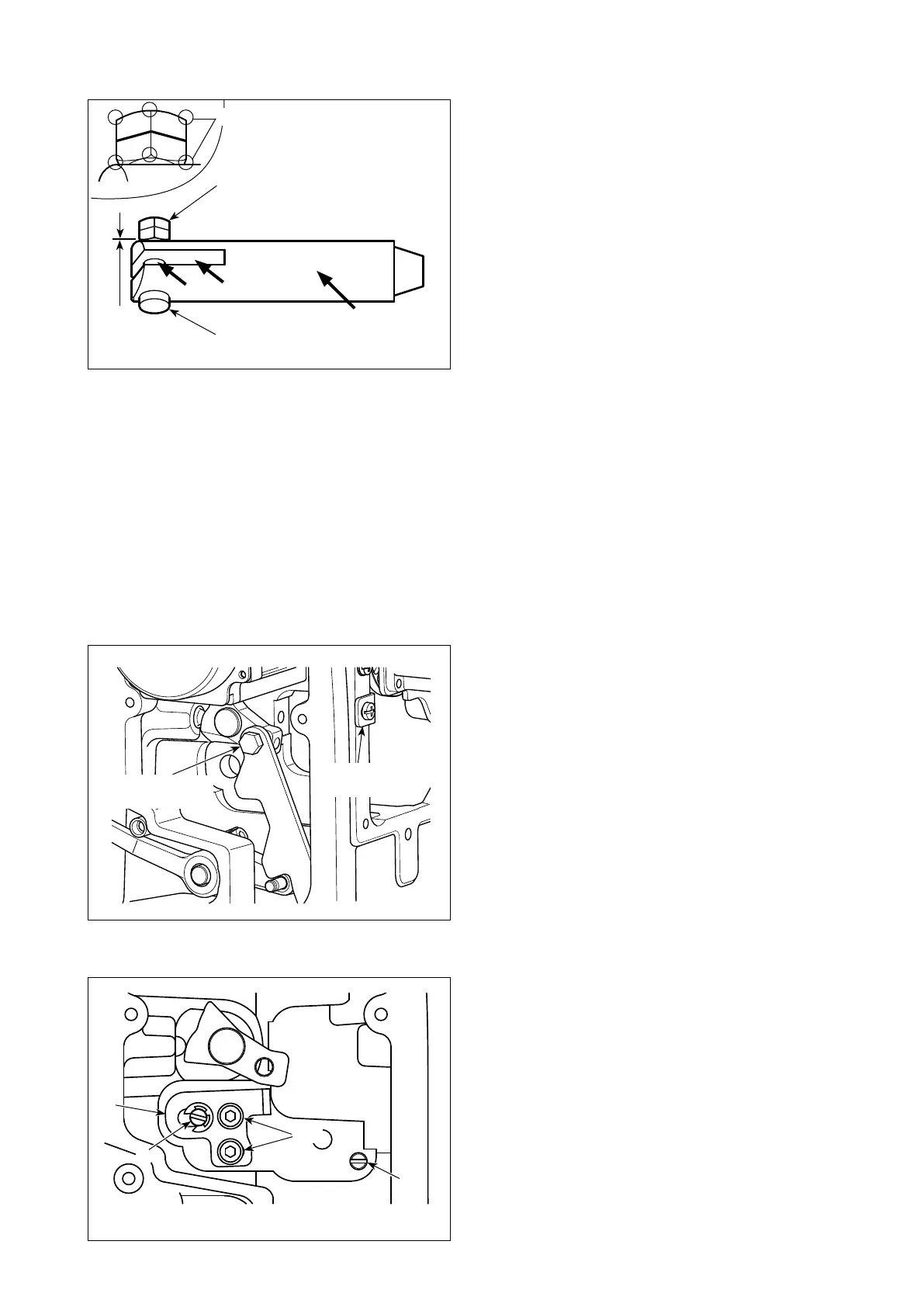

[2] Installing parts to the machine head

①

RemovingtheAKcover,pulleyandelectricalbox

RemovetheAKcover,pulleyandelectricalbox.

②

Removing the motor cable guide and feed adjustment pin

1

)

Removethemotorcableguide.

2

)

Loosenthefeedadjustmentpinsetscrew.

Removethefeedadjustmentpin.

At this time, remember the orientation of the

feed adjustment pin.The forward / reverse feed

adjustment will be easy when installing the pin in

theaforementionedorientation.

③

Installing the condensation stopper and condensation arm stopper

1

)

Secure condensation arm stopper

⓰

to the

positionshowninthegure.

2

)

Insert condensation stopper shaft

⓬

o f

condensation stopper

⓫

into the hole in the arm,

and temporarily secure condensation stopper

⓫

withM5hexagonsocketheadcapscrew

⓮

and

washer, small

⓯

.(Adjustmentistobecarried

outlater.)

Screwtobeused:M5hexagonsocketheadcap

screw, washer small

Loading...

Loading...