–130–

⑦

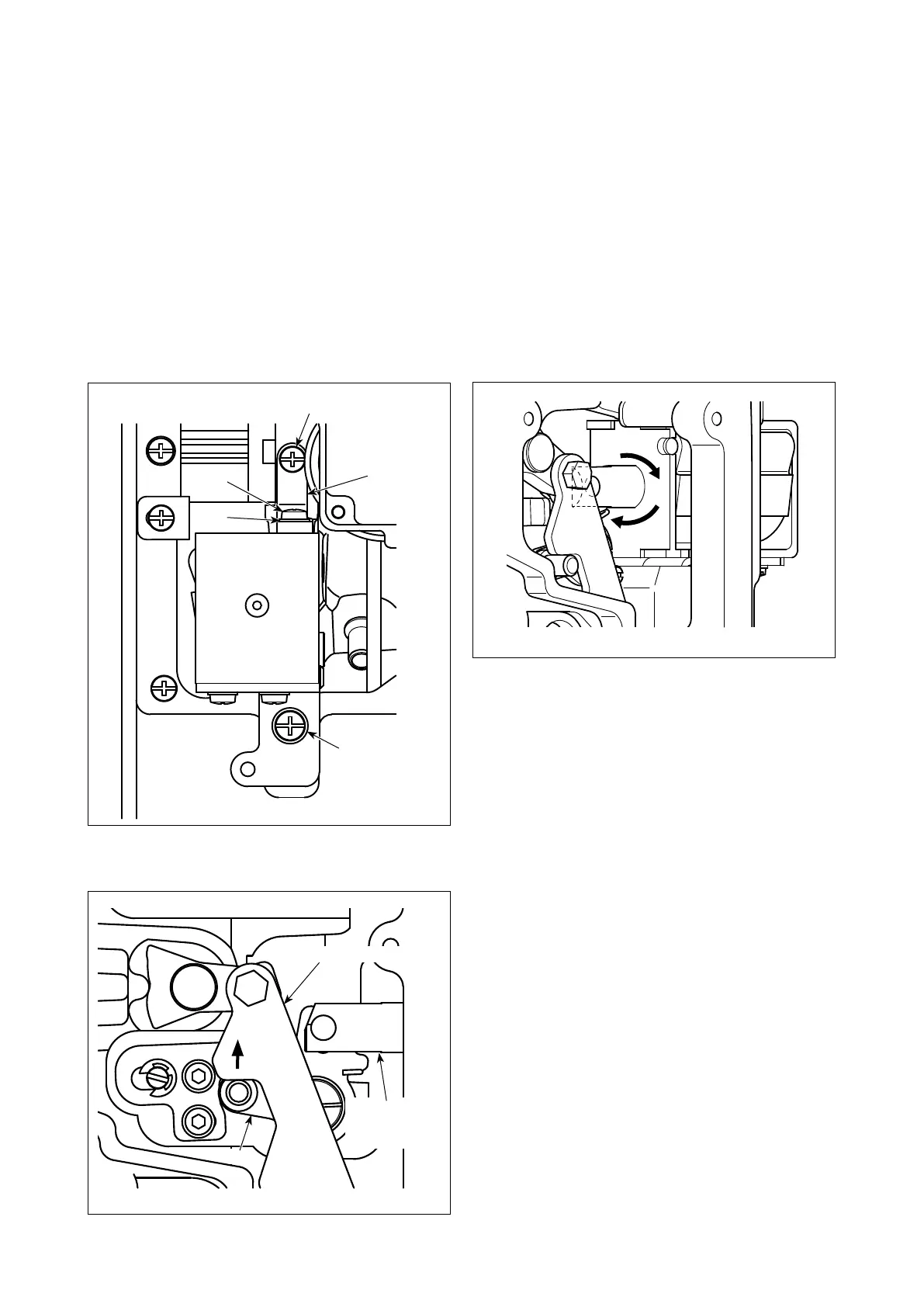

Assembling the condensation solenoid

1

)

Temporarily secure solenoid mounting plate

❷

to the arm with M5 pan head screw, short

❸

.

2)Temporarily secure sub-assembled condensation solenoid to the arm with M6 pan head screw

⓴

and

washer, large

.Then, temporarily securethe condensation solenoid tosolenoid mounting plate

❷

which has been temporarily xed in the aforementioned step 1) with M5 pan head screw,long

❹

and

washer

❺

.

3)Fixscrew

⓴

sothatitisbroughttothetopendoftheslot.Then,tightenscrew

❸

while pressing mounting

plate

❷

againstthecondensationsolenoid.Then,tightenscrew

❹

.

Atthistime,checkrsttomakesurethatthesolenoidplungerisallowedtorotateintheaxialdirection,to

smoothlyrotateandtoreturntoitsinitialpositionbythespring.Then,securelytightenthescrews.

[Tighteningtorque:1.9-2.9N·m(20-30kgf·cm)]

4) After tightening the screws, check to make sure that relevant parts normally operate and the screws are

securelytightened.

❹

❺

⓴,

❸

❷

⇦

❽

Feed adjusting rod

Solenoid

plunger

(Caution) If the solenoid plunger fails to rotate

in the axial direction or fails to operate

smoothly, the solenoid plunger has

been assembled off-center. In this

state, operation failure and abnormal

wear can occur. Re-install the solenoid

plunger correctly.

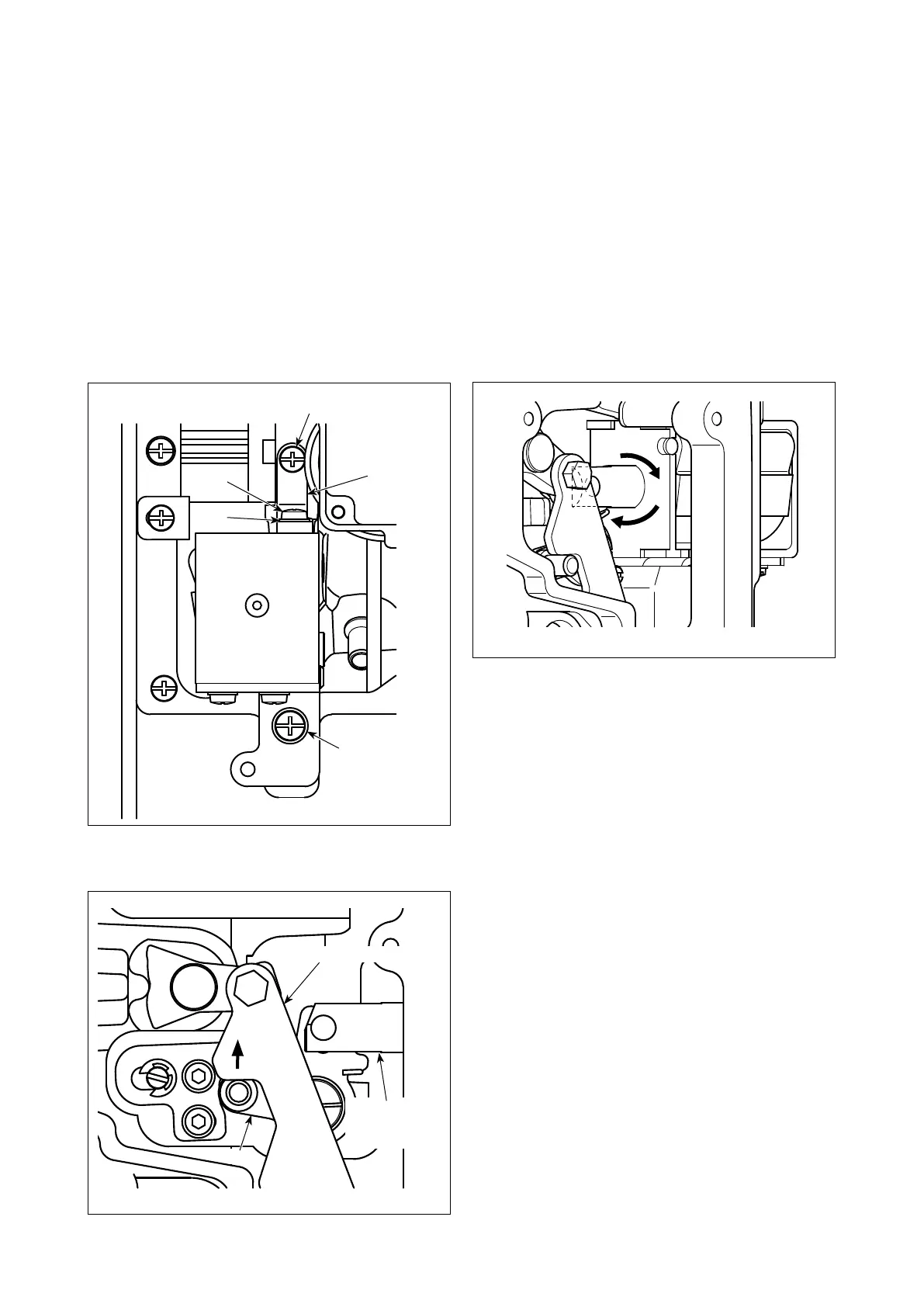

[3] Adjusting the condensation stopper

1)Setthestitchdialto"0.5".(FortheHtypemodel,

setitto"0.75".)

2)Pull the plunger in the directionof the arrow (or

move condensation arm

❽

in the direction of the

arrow) until condensation arm

❽

comes in light

contact

withthefeedadjustingrod.

(Caution)

Take care not to allow the feed adjustment

rod to move. If the feed adjustment rod

moves, the condensation pitch cannot be

adjusted as desired, resulting in thread

trimming failure or in longer remaining

length of thread after thread trimming.

Loading...

Loading...