Keysight N5221A/22A Service Guide 8-3

General Purpose Maintenance Procedures

Error Terms

To find assemblies related to error term failures, refer to error term descriptions

in “Error Term Data” on page 8-8. Each description lists common assemblies

related to each error term. Identify the assembly and refer to Chapter 4,

“Troubleshooting.”

Performing Measurement Calibration

A calibration must be performed to allow the analyzer to calculate the error

terms before they can be used as a tool:

1. Connect a type-N cable to Port 2.

2. Perform a full 2-port calibration, FULL SOLT 2-Port. Refer to embedded

help in the analyzer if necessary.

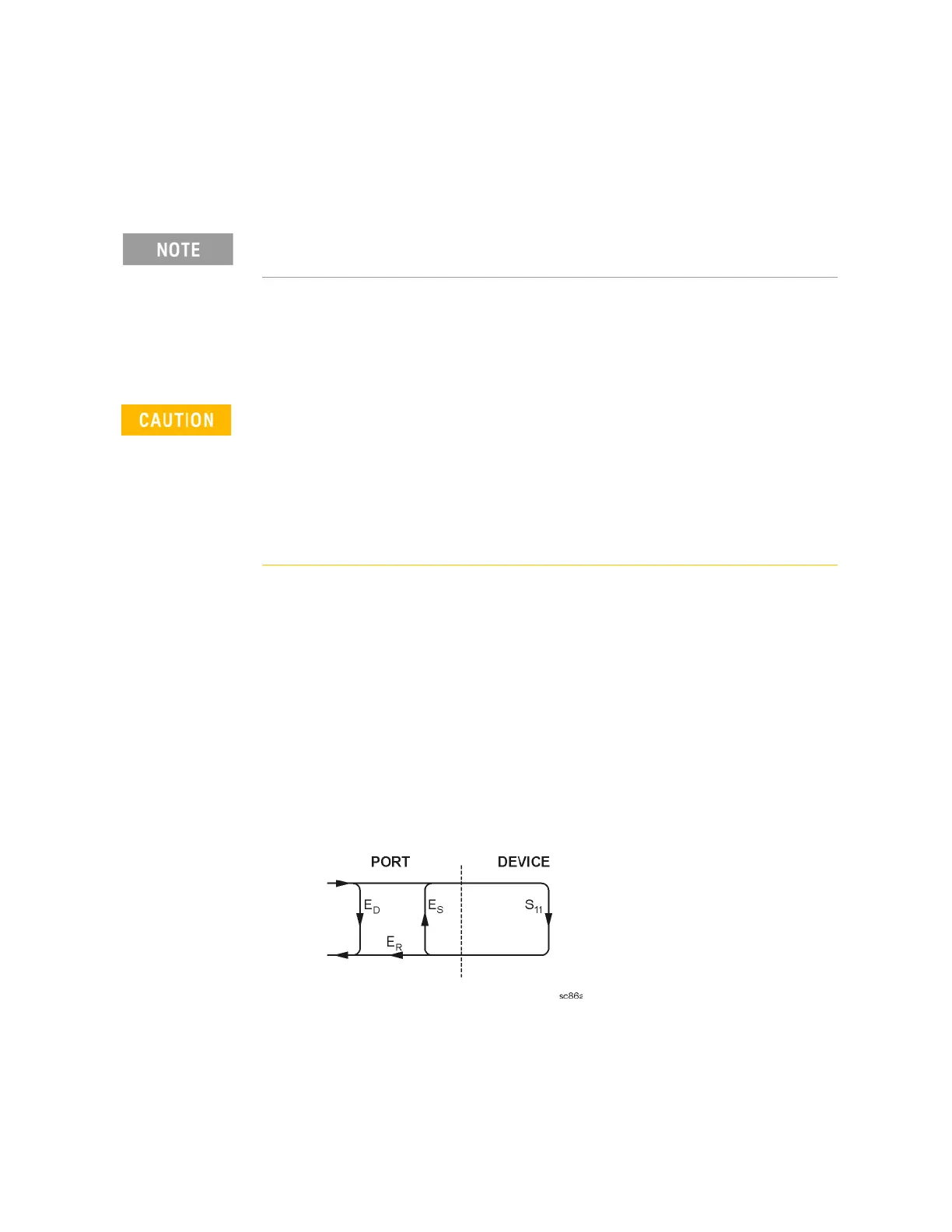

Using Flowgraphs to Identify Error Terms

Flowgraphs are a graphical representation of signal flow through the

measurement path. The flowgraphs in Figure 8-1, Figure 8-2, Figure 8-3, and

Figure 8-4 illustrate the error terms associated with measurement calibration

for 1-port, 2-port, 3-port, and 4-port configurations respectively.

Figure 8-1 Flowgraph of One-Port Error Terms for Port 1

where:

E = Error term

Subscript:

D = Directivity

Always suspect calibration devices, cables, or improper connector

maintenance as the primary cause of an error term anomaly.

Perform the following procedure only at a static-safe workstation, and

wear a grounded wrist strap.

This is important. If not properly protected against, electrostatic discharge

can seriously damage your analyzer, resulting in costly repair.

To reduce the chance of electrostatic discharge, follow all of the

recommendations outlined in “Electrostatic Discharge Protection” on

page 1-7, when performing the following calibration.

Loading...

Loading...