51

The controller HMI Compact or HMI Toutch Panel 4,3`` or 7``

can be connected to the HMI CON port (located in the top

panel of the controller near the USB port) or to the RS485

Master port - if it is not used to transmit information with

the BMS management system. It is possible to connect two

controllers simultaneously, one of them to the HMI CON

port and the other to the RS485 Master port - in this case we

cannot connect the controller from the BMS of the object.

The controller HMI Compact is equipped with a “simple/

ext” jumper, its opening causes the controller to work with

a partially hidden menu, this function will not allow the op-

erator to enter the “service menu”, where we congure the

ventilation system.

The controller menu is always visible in its entirety.

Touch-screen controllers HMI Toutch Panel 4,3` or 7`` HMI

are operated by a controller equipped with an additional

memory card, such a controller is marked with an addition-

al “+” symbol on its label.

The USB connector is used to upload the controller applica-

tion, if the application of the controller does not meet the

requirements of the customer contact the manufacturer

or supplier, it is possible to adapt the application to the

requirements and upload it using any PC class computer.

1.3 Standard functions of controller I/Os

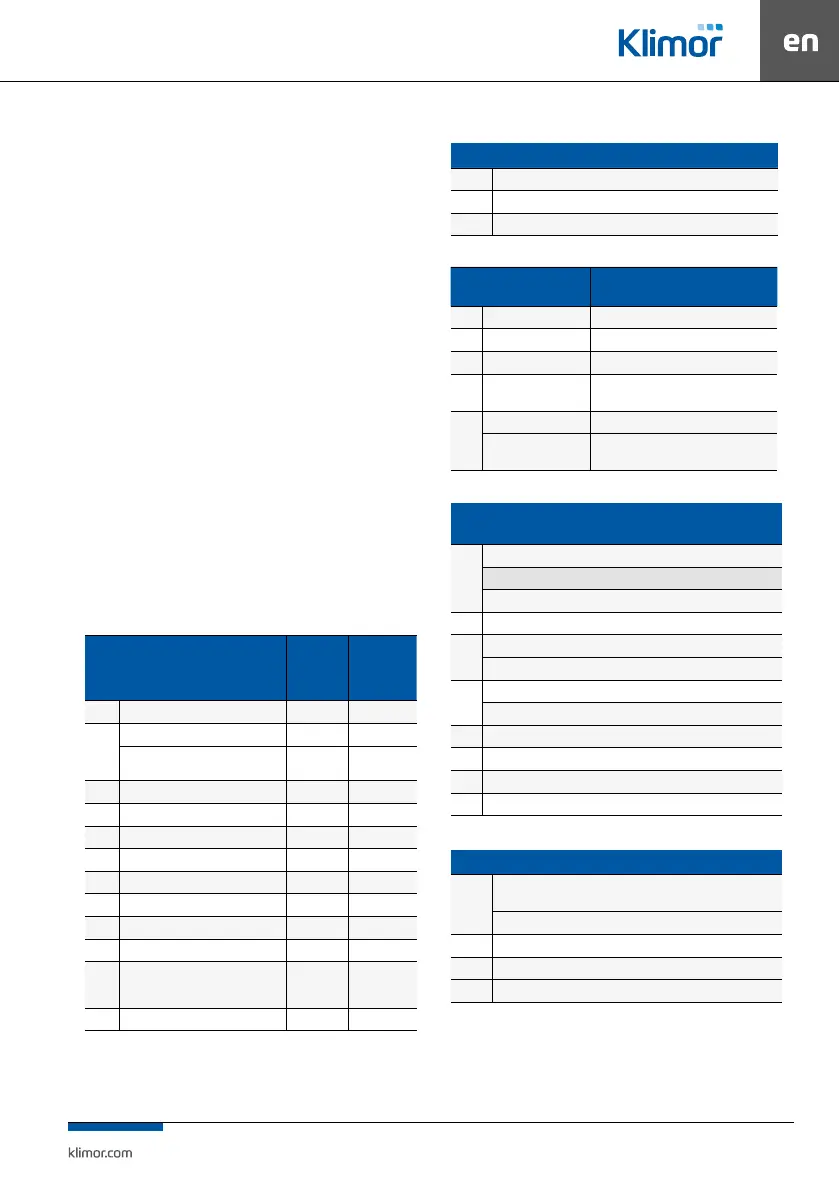

Table No. 1 List of digital inputs

Digital inputs (Input NC state – supplying

24VAC to DIN... input switches on the digital

input)

During

correct

system

operation

Lack of re-

quired state

triggers the

alarms

Din 1 Fire alarm system shorted A_AF

Din2

Water heating coil anti-freeze thermostat shorted A_ThHW

Alarm signal of the electric/gas heater

control system

shorted

A_ThHE,

A_ThGAS

Din3 DX chiller alarm signal open* A_CX

Din4 Air supply/exhaust lter pressure gauge open A_Cold_Rec

Din5 Air supply fan pressure guage open A_SupFilter

Din 6 Exhaust lter pressure guage open A_ExhFilter

Din 7 Supply fan pressure guage shorted A_SupPres

Din 8 Defrost signal from the reversing unit shorted A_ DefFunc

Din 9 Supply fan inverter/fan EC EBM alarm shorted A_SupFC

Din 10 Exhaust fan inverter/fan EC EBM alarm shorted A_ExhFC

Din 11

Additional/electrostatic supply air lter

pressure guage (optional)

shorted

A_SupFilter2

or A_SupFil-

terES

Din 12 Service switch/remote start/stop switch shorted A_StopS1

Table No. 2 List of analog inputs

Analog input (0÷10VDC signal )

Ain1 Pressure sensor - supply

Ain2 Pressure sensor - exhaust

Ain3 Air quality sensor CO2, LZO, PM2.5, or PM10

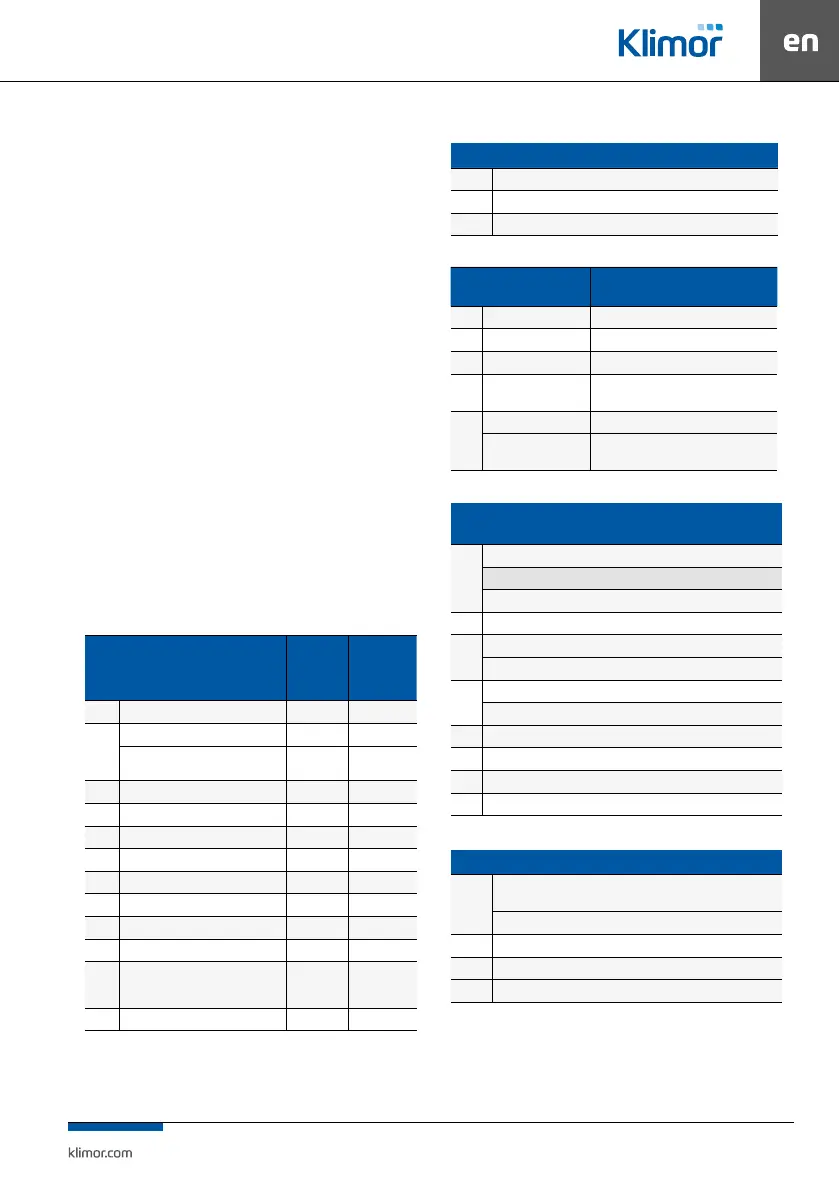

Table No. 3 List of temperature sensors

PT1000 Temperature sensor

Faulty temperature sensor triggers an

alarm which stops the system

PT1 Air supply A_Tsup

PT2 Air exhaust A_Texh

PT3 External A_Tout

PT4

Air exhaust downstream

heat recovery

A_Trec

PT5

Optional leading A_Tmain (when PT5 is selected as the lead sensor)

Return water sensor of

the water heater

A_TbackWater (when the return water sensor

of the water heater is activated)

Table No. 4 List of digital outputs

Digital outputs, switched o state – ReC/ReA output open,

switched-on state – ReC/ReA output shorted

Re1

Water heater pump

Water heater and water cooler pump if H/C water exchanger is activated

Electric heater

Re2 Start of the rotary recovery

Re3

Chiller for water cooler

DX cooler stage I

Re4

DX cooler stage II

Season signal SUMMER (if H/C water exchanger is activated)

Re5 Supply/exhaust air dampers

Re6 Permission to operate electrostatic lters

Re7 Fan operation signal / UV-C lamp control

Re8 Collective alarm signal

Table No. 5 List of analog outputs

Analog output (0÷10VDC signal output)**

Aout1

Heater (water, electric or gas heater equipped with its own power supply

module)

Water heater and cooler (if H/C water exchanger is activated)

Aout2 Cooler (water or DX cooler equipped with its own power supply module)

Aout3 Mixing chamber (10-0V), supply/exhaust air dampers (0-10V)

Aout4 Cross-ow heat/cool recovery

* Possible negation of digital input in Settings/DX cooler menu.

** In the service menu you can select one of the analog outputs as the 0÷10V signal of air

supply fan exhaust fan.

Note!!! Connect the supply and exhaust humidity sensors using modbus

RS485 communication

Loading...

Loading...