54

AUTOMATION AND CONTROLLER FOR UNITS EVO-T; EVO-T COMPACT

OPERATION AND MAINTENANCE MANUAL

The temperature limit parameters “Air supply Tmin”,

“Air supply Tmax” can be similar to the preset temperature

setting.If there is no setting stabilization for recommend-

ed settings you can increase Ti of each controller by 10s

(max up to 120s).

The selection of cooling time of the heater, should be made

in such a way that the electric heater does not overheat.

Each application has the ability to work fans with constant

air volume, this mode can be activated in the “Service

Menu/Conguration/CAV”, also install pressure guage with

a range corresponding to the requirements of the system,

on the supply and/or exhaust fan in such a way that the

pressure measurement “+” is in front of the fan and the “-”

behind the fan, connect the measuring signal to the analog

inputs according to the I/O list (p.1.2) and congure the

pressure control using the “Settings/Fans/CAV” and “Set-

tings/Regulators/PI CAV” menu.

Each application has the ability to work with an air quality

function depending on the CO2 sensor or VOC sensor. In

case of poor air quality, the amount of fresh air is increased

by means of a mixing chamber or fan capacity. The air qual-

ity function can be congured in the service menu / cong-

uration / air quality.

Each application has the ability to work with an air quality

function depending on the PM2.5 sensor or PM10 sensor.

In case of poor air quality, the electrostatic lter is switched

on and the amount of fresh air is reduced using fan capaci-

ty. The air quality function can be congured in the service

menu / conguration / air quality.

If you change your app, be sure to restore the sys-

tem to the factory state “Service Menu/Factory

Reset” in advance.

The system is started, if:

• There is no alarm blocking system operation

• “S1 – service stop” signal is shorted at the DIN12 input of

the controller

• “S1F – re alarm” signal is shorted at the controller DIN1

input

• “Set operation mode” parameter at the controller or pro

-

gramming device is set to any other option than Stop.

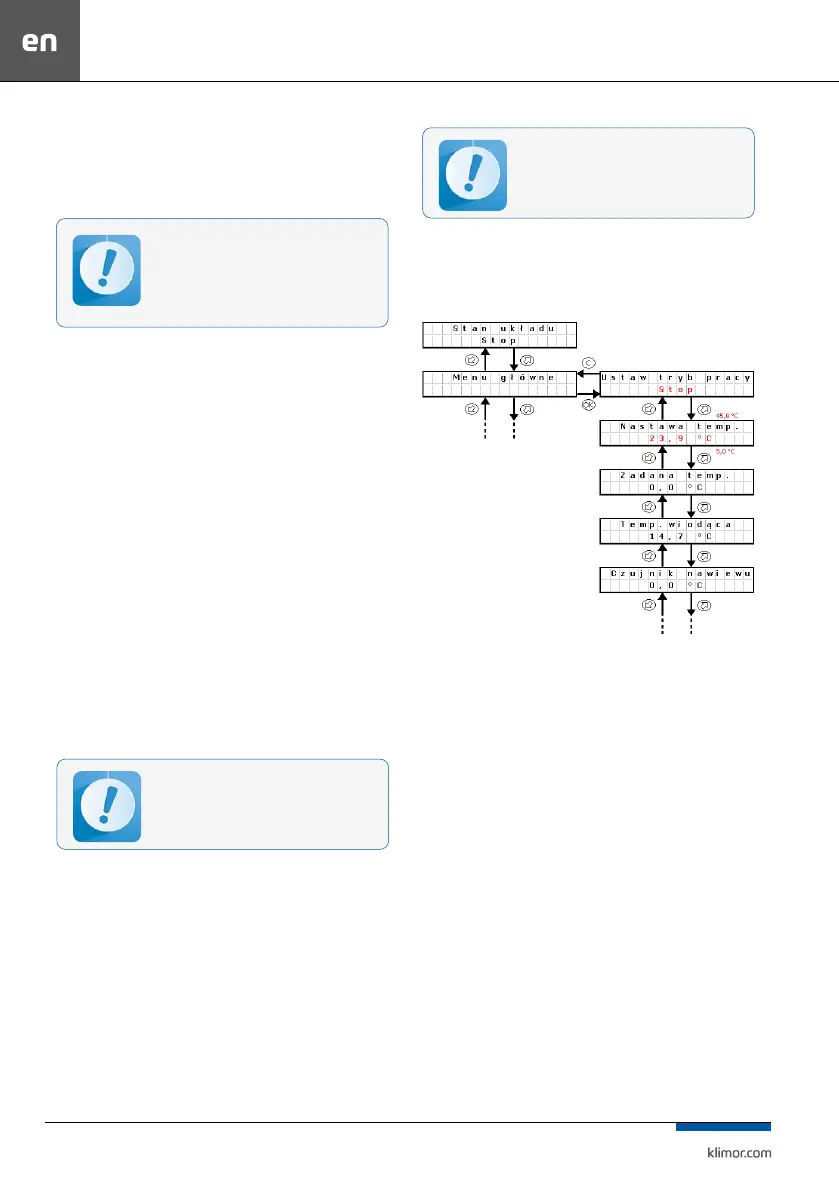

3.2 Changing set temperature

On the controller or programming device in the main menu,

“Temperature settings” parameter.

Fig. 4 Changing set temperature

Changing operating mode:

Press OK button. “Stop” starts blinking. Switch to another

mode and conrm with OK button.

Changing the temperature setting:

Press OK button “23.9..” starts blinking. Switch to another

value and conrm with OK button.

3.3 Standby mode

In order to save energy the control system is able to oper-

ate in standby mode. Select this mode using “Operation

mode” setting in the main menu of the controller or in the

timer. Depending on the requirements it is possible to set

the standby mode only for heating, only for cooling or

both for heating and cooling (see point 4.3).

Below there is a description of system reaction when

switching from the operation into standby mode (heat

-

ing).

System I – system is stopped,

System II – system is switched on for operation, fans and

heat/cool exchanger are started, master temperature is

adjusted (in this case Tsup – air supply) up to the set tem

-

perature 22°C

No system stabilization in case of such set-

tings selection can indicate wrong selection

of heat/cool exchangers, their incorrect oper-

ation, missing required parameters of heat/

cool nodes, set according to the AHU selection

sheet.

After power cut-o, the system automatically

resets to the settings operating before the power

cut-o.

Loading...

Loading...