53

3. CONTROL OPERATION

3.1 Starting-up the system

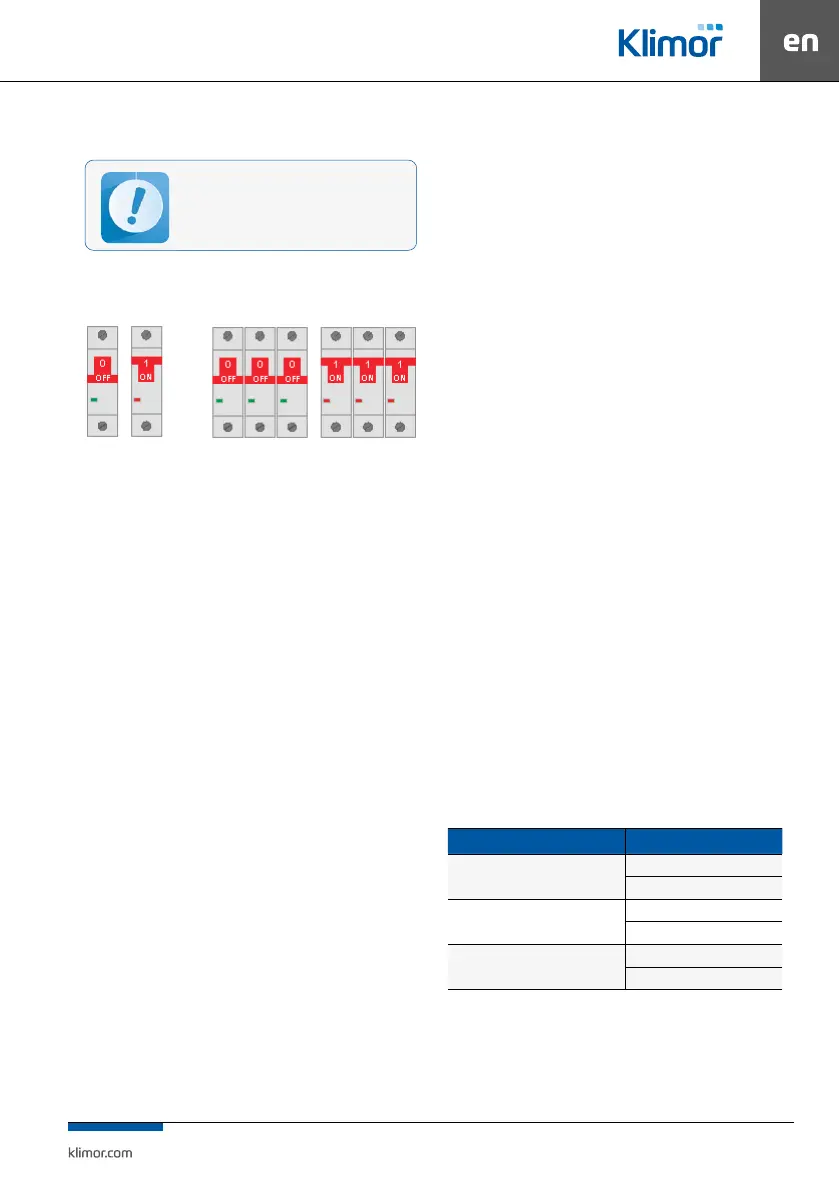

Turn the Q1M trip switch into ON position:

“1-ON” (plastic control unit)

Fig. No

3 Control cabinet switches

In order to start up the system for the rst time:

a) Read this manual and application diagram for a ventila

-

tion system, where the control system is to be applied.

b) Carry out electrical connections in line with the applica-

tion diagram and guidelines listed in this manual.

c) Check, if the sensors and functional elements (actuators,

inverters, etc.) are connected correctly.

d) Turn on the power supply of the control cabinet and set

the application code in the service menu according to the

application diagram (Tab. No 8).

e) Set up the system in the service menu (p.4,4).

f) Deactivate the service mode.

g) In EBM fan systems, set the addresses (when loading

addresses, the EBM fan conguration is performed), so the

above operation should also be performed on all EBM fans

connected to the controller,

h) Turn on the Modbus RTU controller communication with

the EC EBM fans or inverters of air supply and AC air exhaust

fans (if equipped) (p.4.3).

i) Check if the sensor readings and locations are correct.

j) Check operation of the actuators (using Service menu/

output forcing). While testing please pay attention to free

motion of dampers, full open/close state of the actuators.

k) Set the master sensor in “Settings/Temperatures/Master

sensor” menu (p.4.3)

l) Check if any alarms are triggered. If so, they must be

cleared (p.3.4)

m) Start the system (p3.1)

n) Check again if any alarms are triggered. If so, they must

be cleared (p.3.4)

o) Choose the right menulanguage at the controller

Regardless the controller’s factory settings please check the

adjustment of the system in terms of temperature adjust-

ment, cooling the electric heater (if equipped).

Selection of temperature controller settings should be

carried out so that the system introduces the corrections

as soon as possible, without over-regulation (decrease the

Kp parameter and/or increase the Ti parameter in order to

slow down the system response).

Appropriate selection of PI controller settings, operating

the AHU in accordance to performance determined in the

AHU specication sheet, appropriate selection of AHU

components (recommended analog control of each heat/

cool exchanger), system operation at a premise with no

sudden temperature changes due to presence of other

equipment generating high amount of heat/cool, enable

stable control of lead temperature.

In order to check current accuracy of temperature control

please go into “Service menu/Lead temperature history”

(where last 15 measurements of lead temperature sensor

with selected time period are stored) as well as the “Devi

-

ation” is provided, which determines the max. dierence of

current set temperature and last 15 measurements from the

master temperature sensor.

In case of unsatisfactory results of temperature control

process, you have to:

• check if the system operates at its full performance (com

-

pare the frequency of the fan inverters/ compare the

degree of control of the EC motors with the operating

frequency/degree of control given in the panel’s technical

data sheet or with the data obtained from the results of

performance measurements),

• check operation of the actuators and control circuits of the

heaters, coolers and recovery systems,

• check operation of the air dampers,

• check if the temperature sensors are installed correctly,

• check selection of the Pl controllers settings.

Cascade controller – cascading controller in which system

startup is carried out only with the air supply temperature

controller with duration determined in „Settings/Temper

-

ature/Preset temperature ramp” menu, and once this time

passes (if the master sensor is dierent than the air supply

sensor) an additional controller of lead temperature is pro-

vided in order to apply the present temperature setting of

the air supply controller.

Table no. 9 Controller – total of temperature controllers: main, min limit, max limit

Name in menu Factory setting (recommended)

Heating Pl

Kp = 1

Ti = 60s

Cooling Pl

Kp = 1

Ti = 60s

Air supply Pl (air supply Tmin limit, air

supply Tmax limit)

Kp = 1

T1 = 90s

Air supply Pl of the controller can be faster or slower than

heating and cooling Pl. The slower the Pl is, the smaller the

oscillations at min and max air supply temperature but the

reaction to the limit is slower.

Before the user starts the system, the control

cabinet shall be connected and checked by the

authorised personnel.

Loading...

Loading...