56

AUTOMATION AND CONTROLLER FOR UNITS EVO-T; EVO-T COMPACT

OPERATION AND MAINTENANCE MANUAL

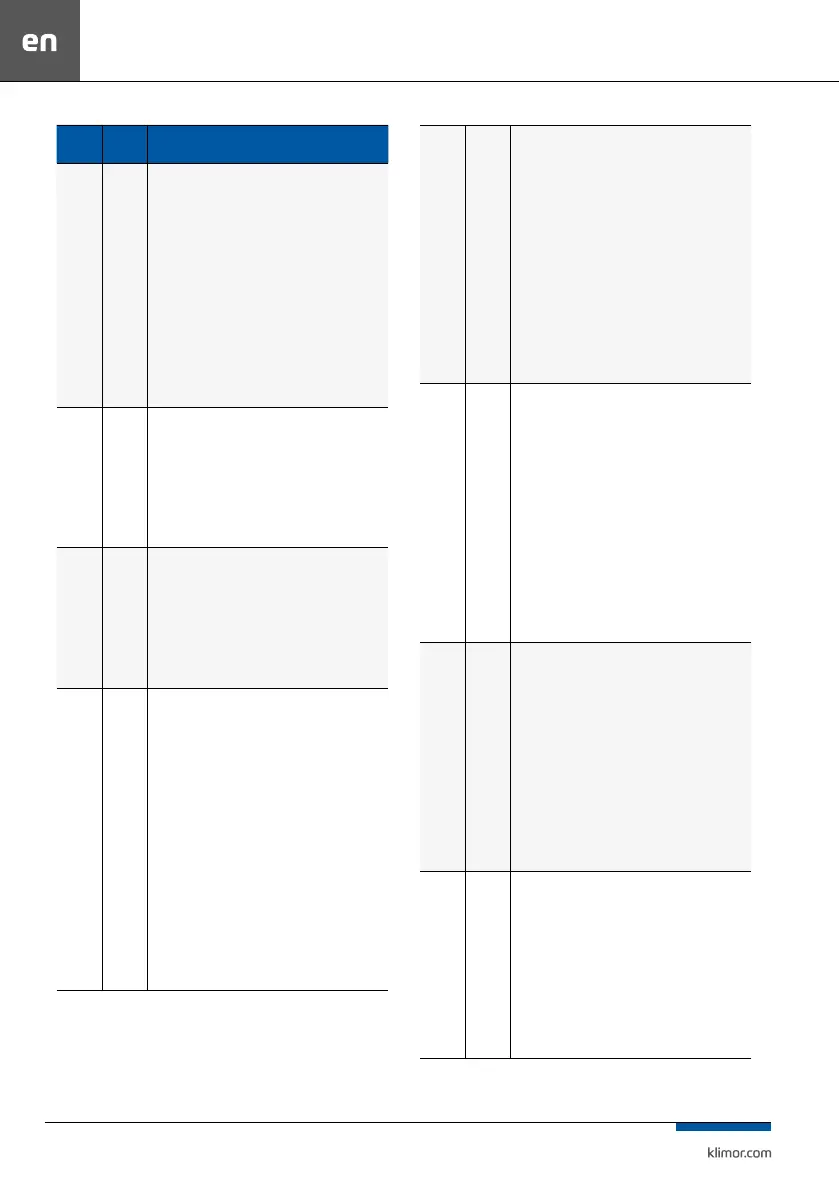

Alarms

Alarm

type

System response, action / Alarms list

A_ThHE, A_3xThHE

Fading

Blocking

Overheat protection of the electrical heater, a signal

from alarm relay of the HE module installed in the po-

wer supply control cabinet which controls the electrical

heater is feed to this input:

Normal condition – heater temperature is low, 24VAC signal on

the digital input

Alarm condition – heater temperature is too high, there is no

24VAC signal on the digital input

Response to the alarm condition: the system operates without

the heater until overheating is eliminated, once overheating is

eliminated the alarm disappears and the system operates with

the heater, if the A_ThHE alarm is triggered 3 times within

1 hour, the system is stopped and the A_3×ThHE alarm is

displays, which has to be conrmed.

Digital input Din2

A_DX Fading

Cooperation with the chiller alarm contact:

Normal condition - no chiller alarm, no 24VAC signal on the

digital input

Alarm condition - there is chiller alarm, there is a 24VAC signal

on the digital input

Response to the alarm state: information signal.

It is possible to change the NO setting to NC .

Digital input Din3

A_FX Fading

Cooperation with the reversing unit alarm contact:

Normal condition - no reversing unit alarm, no 24VAC signal on

the digital input

Alarm condition - there is reversing unit alarm, there is a 24VAC

signal on the digital input

Response to the alarm state: information signal.

It is possible to change the NO setting to NC.

Digital input Din3

A_Col-

dRec

Fading

Frosting test of the recovery outlet part with a pressure

switch:

Normal condition - there is no frosting, the pressure dierence

before and behind the recovery is below the preset value on

the pressure switch, there is no 24VAC signal on the digital

input.

Alarm condition - there is frosting, the pressure dierence

before and behind the recovery is above the preset pressure,

there is 24VAC signal on the digital input

Reaction to the alarm state: the system is in operation, the

recovery control is reduced, after the alarm has disappeared,

the system is in operation with the recovery, if the temperature

control process requires it, if the alarm does not go away for a

longer period of time the recovery system should be checked

and brought to the state from before the alarm

Digital input Din4

It is possible to use the temperature sensor for the frosting test,

see Settings/Service Menu/Recovery Sensor

Sensor input PT4

A_Sup

Filter

Fading

The air supply lter contamination level inspection

using the pressure gauge:

Normal condition – permissible contamination level, pressure

dierence downstream and upstream the lter is lower than

the one set on the pressure gauge, no 24VAC signal at digital

input

Alarm condition – unacceptable contamination level, pressure

dierence downstream and upstream the lter is higher than

the one set on the pressure gauge, 24VAC signal at digital input

Response to the alarm condition: the system operates, the con-

taminated lter alarm is displayed, if such alarm occurs, install

the new lter immediately, AHU operation with contaminated

lter can reduce the AHU eciency and can lead to the lter

damage which in turn can cause contamination and damage

of heat/cool exchangers (that would be a customer’s fault).

Digital input Din5

A_Exh

Filter

Fading

The air exhaust lter contamination level inspection

using the pressure gauge:

Normal condition – permissible contamination level, pressure

dierence downstream and upstream the lter is lower than

the one set on the pressure gauge, no 24VAC signal at digital

input

Alarm condition – unacceptable contamination level, pressure

dierence downstream and upstream the lter is higher than

the one set on the pressure gauge, 24VAC signal at digital input

Response to the alarm condition: the system operates, the con-

taminated lter alarm is displayed, if such alarm occurs, install

the new lter immediately, AHU operation with contaminated

lter can reduce the AHU eciency and can lead to the lter

damage which in turn can cause contamination and damage

of heat/cool exchangers (that would be a customer’s fault).

Digital input Din6

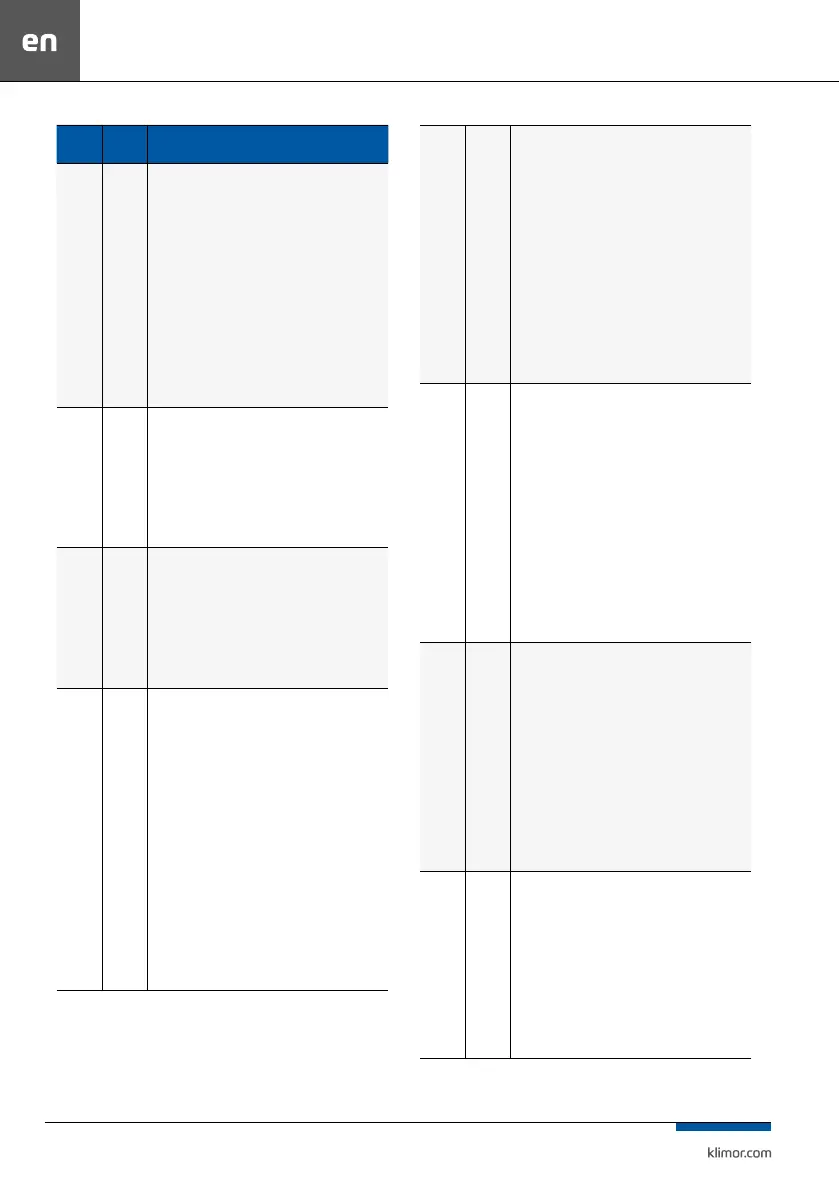

A_Sup-

Pres

Blocking

Air supply fan operation inspection using the pressure

gauge:

Normal condition – fan compression is examined 30 seconds

after starting the system, pressure dierence downstream and

upstream the fan should be higher than one set on the pressu-

re gauge, 24VAC signal at digital input

Alarm condition – no fan compression 30 seconds after starting

the system, pressure dierence downstream and upstream the

fan is lower than one set on the pressure gauge, no 24VAC

signal at digital input

Response to the alarm condition: the system is stopped, check

the fan and nd out the problem with compression, once the

problem is eliminated conrm the alarm and start the system

Digital input Din7

A_Sup-

FC

Blocking

Air supply fan operation inspection using the inverter

alarm contact or EC motor controller:

Normal condition – no alarm immediately after starting the

system, alarm contact is shorted, 24VAC signal at digital input

Alarm condition – alarm immediately after starting the sys-

tem, alarm contact is open, no 24VAC signal at digital input

Response to the alarm condition: the system is stopped, check

the inverter and its connection to the controller and the fan,

nd out the problem source, once the problem is eliminated

conrm the alarm and start the system.

Digital input Din9

Loading...

Loading...