66

AUTOMATION AND CONTROLLER FOR UNITS EVO-T; EVO-T COMPACT

OPERATION AND MAINTENANCE MANUAL

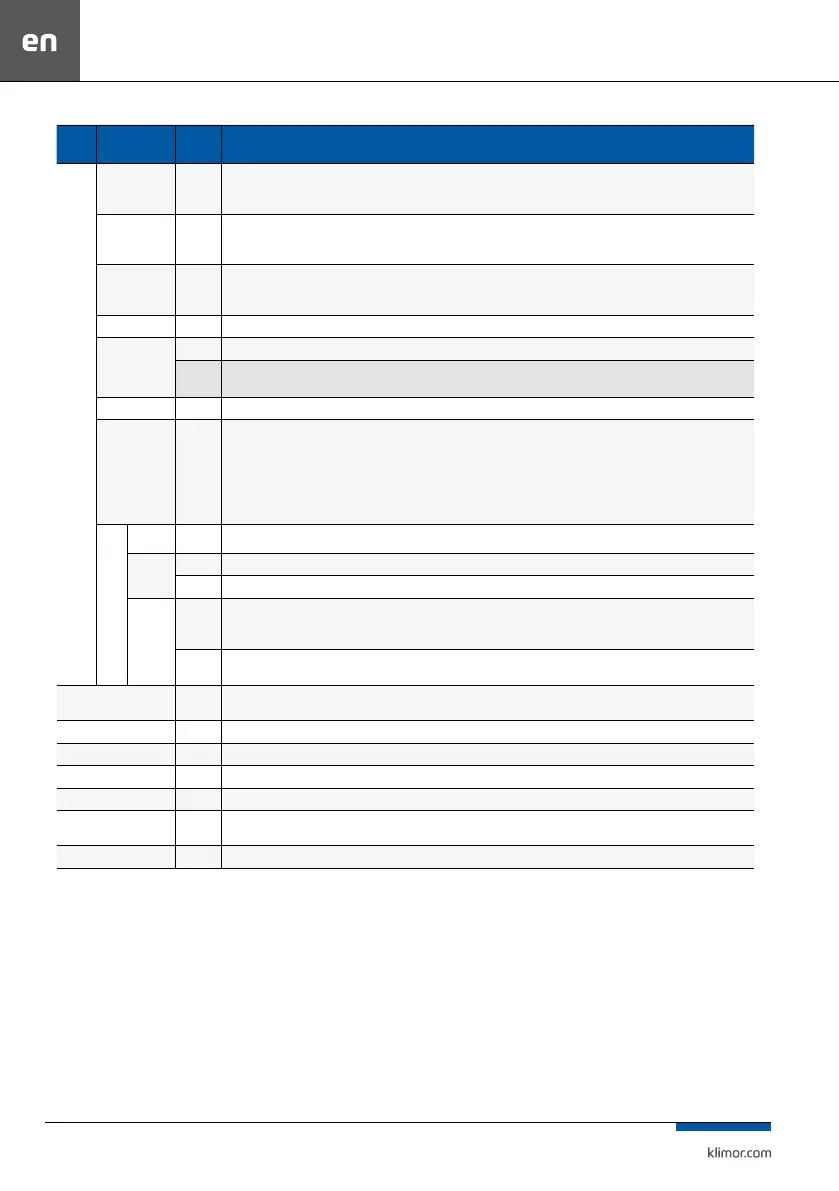

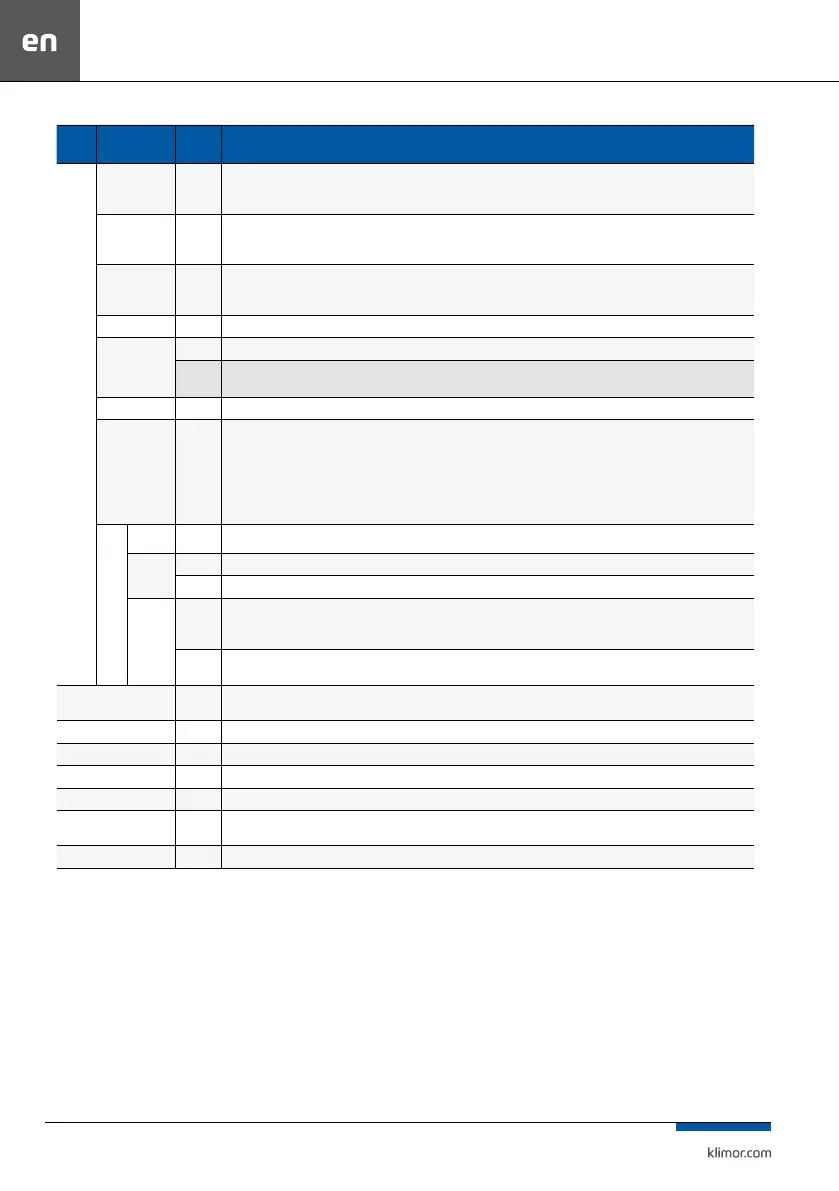

Name Name

Default

value

Description / Service menu

The set

up

DIN12 Function A_StopS1

A_StopS1 - opening the DIN12 input will stop the system and display an alarm A_StopS1 (used when the DIN12 input function is service stop)

ON/OFF - opening the DIN12 input will stop the system without an alarm A_StopS1 (used when the DIN12 input function is the remote start/

stop of the system)

1S2H Function

Secondary

lter

Secondary lter - when 24V signal is given to DIN8 input, dirty secondary lter is signaled by alarm A_SupFilter2.

Electrostatic lter - passing a 24V signal to the DIN8 input signals a dirty secondary lter through the A_SupFilterES alarm and the system

reaction according to the next setting.

ES Reaction

Do not

block

Do not block - the dirty electrostatic lter alarm triggers an informational alarm only.

Block - the dirty electrostatic lter alarm causes an alarm blocking the system operation (switching o with cooling of gas, electric or freon

heaters).

Analogue outputs - Possibility of scaling the output signal 0-10VDC to 2-10VDC (check the compatibility of signals in the OMM of cylinder damper, valve)

Communication

0.3 s Tcom – time of communication with device with Modbus communication in SLAVE mode (inverter

3 s

Twait - response time for communication with the inverter device with Modbus communication Factory default setting for up to 9 devices with

Modbus communication, with more devices the Twait time must be in-creased acorrding to the rule (number of Modbus devices x Tcom) + 0.3s.

Layout number 1 Ventilation system number setting, AHU name with number visible in the controller menu and on the HMI transmitters

HMI Multi Inactive

HMI Multi - the possibility of activating the operation of many EVO_T systems with one TP4,3 or TP7 touch referencing device in the HMI multi

function, the maximum number of controllers operated from one referencing device is 16pcs, the controllers and the panel should be connected

in the serial topology RS485 with a high quality communica-tion cable.

For proper operation of HMI Multi function all systems must have the same version of universal application EVO-T.

In case of dierent versions of the application, it is possible to order custom applications, dedicated only for a given series of circuits with the HMI

Multi function supporting a given series of circuits.

Run-

ning

Timer

Running

time

... H/min Running time - readout of the current running time of the system

Set counter

... H Enter operating time - possibility of entering the running time

No Set counter - entering / resetting to the set running time

A_UV_

LampTime

Inactive

Activation of the A_UV_LampTime alarm, indicating exceeding of the UV lamps running time

Note: when lamps are present in the conguration of the control panel, it is necessary to activate the parameter in order to maintain the control

of lamp life

18000h

Limit - UV lamps running time limit setting

Note: the setting must be in accordance with the lamp manufacturer’s guidelines

Lead temp. history -

Last 15 saved measurements from the lead temperature sensor with selected record period) and provided „deviation” which is the max dierence

between the current preset temperature and last 15 measurements from the lead temperature sensor

Input reading - Reading inputs of the controller during normal system operation

Reading the outputs - Controller outputs readings during normal system operation

Input emulation Possibility of emulating inputs, during the emulation an alarm is reported but the system is working

Outputs forcing Possibility of forcing outputs, during forcing an alarm is reported, but the system is working.

Change password -

Change of password for accessing advanced options. Default password: 1111

Note: if the password is lost or forgotten it is not possible to change advanced parameters

Restore default settings - Restoring initial values of all settings.

Loading...

Loading...