19

18

17

16

20

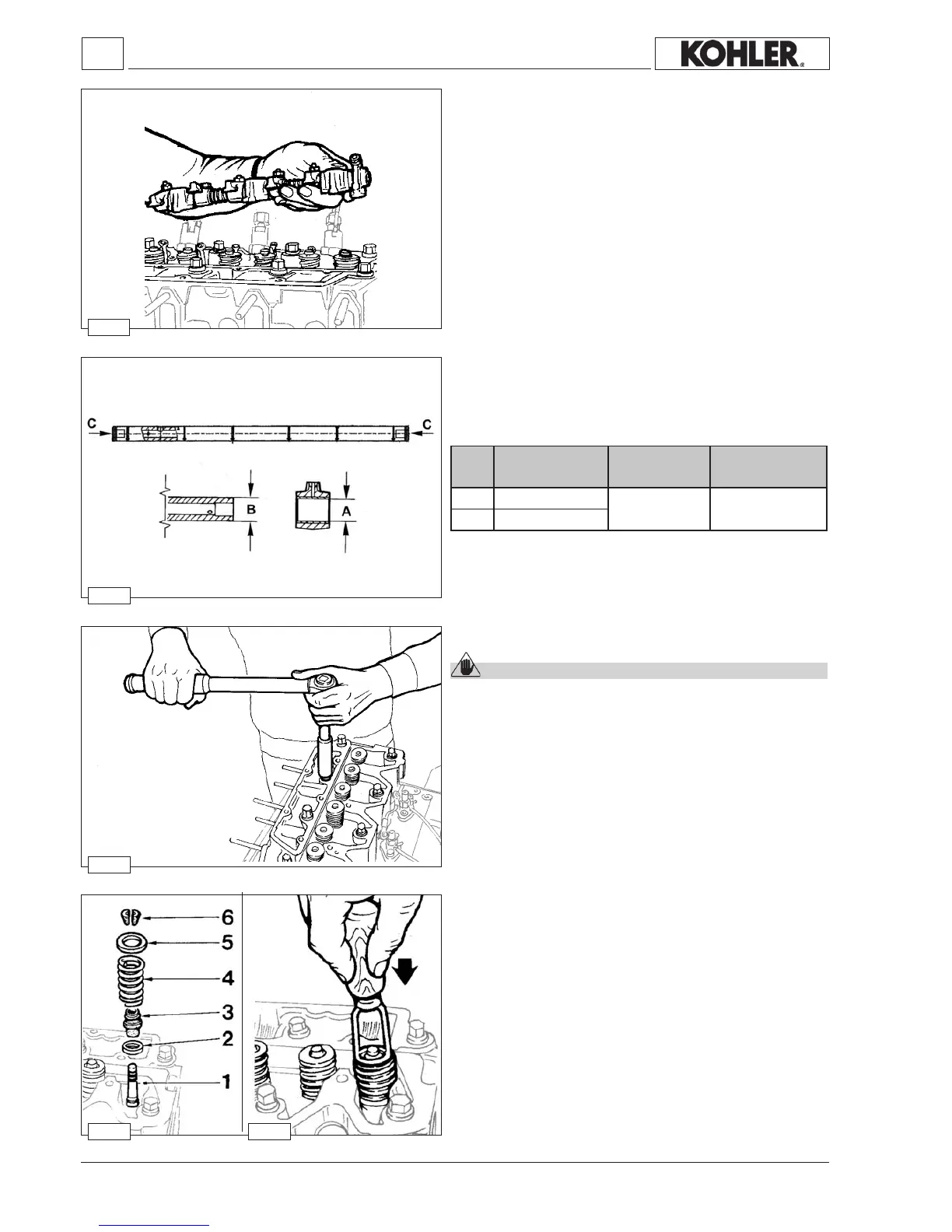

ØA* 14,032÷14,050 ØA-ØB=

0,043÷0,050

0,014

ØB 13,989÷14,000

6

- 40 - - 40 -

Disassembly / Reassembly

Tocheckthepinandtherocker-armpinbearingsforwearcompare

themeasuredvalueswiththeparametersinthetablebelow.

Table of pin-rocker arm dimensions

* Withbushingttedtotherockerarmandreamed.

Clearance

(mm)

Limit value (mm)

Dimensions

(mm)

Ref.

Cylinder head

Caution – Warning

Do not demount when hot or the part could become

deformed.

Donotremovewhenhottoavoiddeformation.

Check cylinder head plane using a metal straight edge and

thickness gauge; if warpage exceeds 0.10 mm, level off by

removingamaximum0.20mm.

See pictures 56÷59 (pages 39÷40) for cylinder head

tightening.

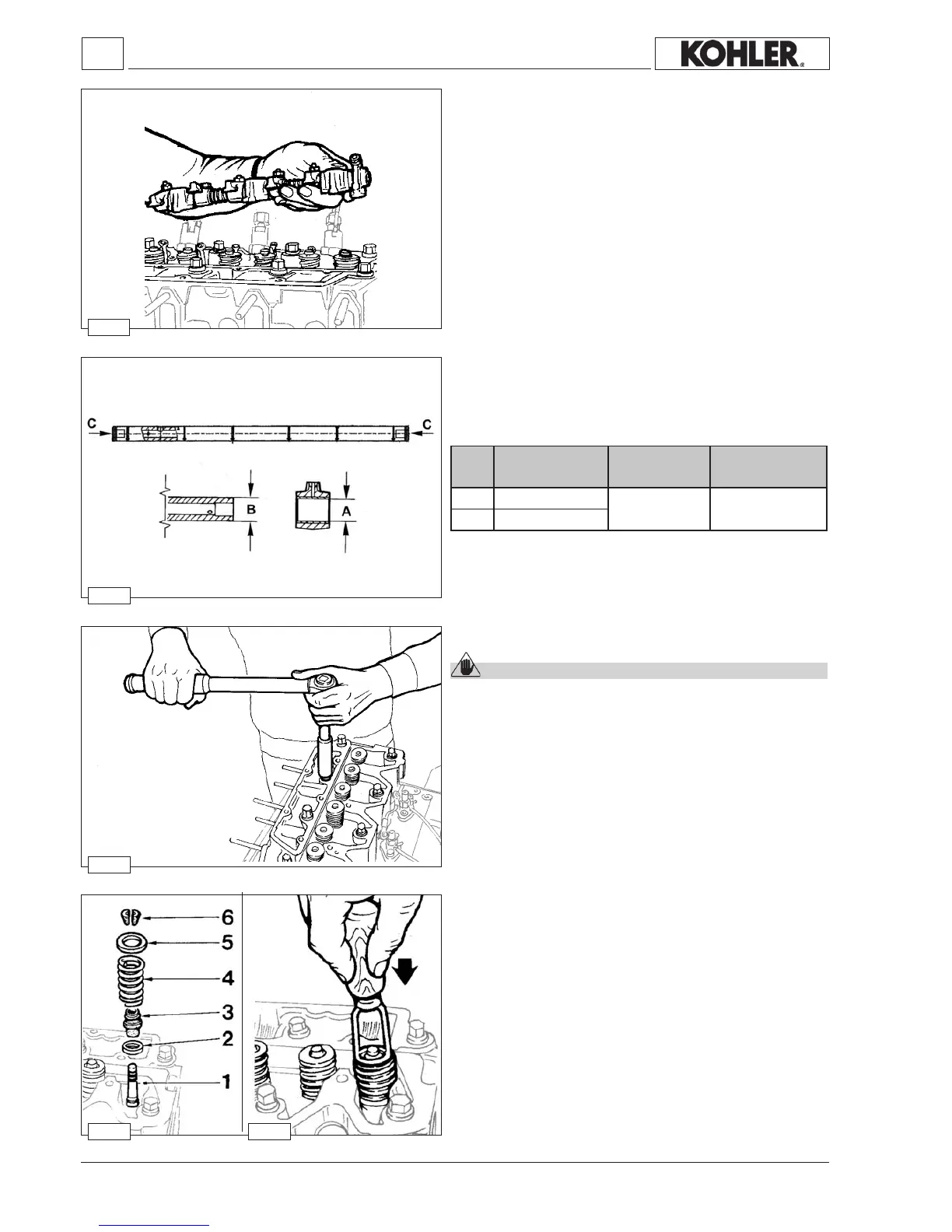

Valve removal

Components:

1

-Valve

2-Lowerspringseat

3-Valveguideseal(forintakeonly)

4-Spring

5-Springcap

6-Cotters

Toremovethecottersrmlypressdownasshowninthegure

20.

Rocker arm assemly

Loosenthescrewswhichfastentheassemblytothehead.

WhenrettingapplyadropofLoctite270ontothethreads.

Whenrettingtightento50Nm.

Insidetherockerarmpinowstheoilthatlubricatestherocker

armsandfeedsthehydraulictappets.

To clean the rocker-arm pin inside, remove the two tightening

screwsC attheends(g.17).

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

Loading...

Loading...