167

10

- 82 - - 82 -

a

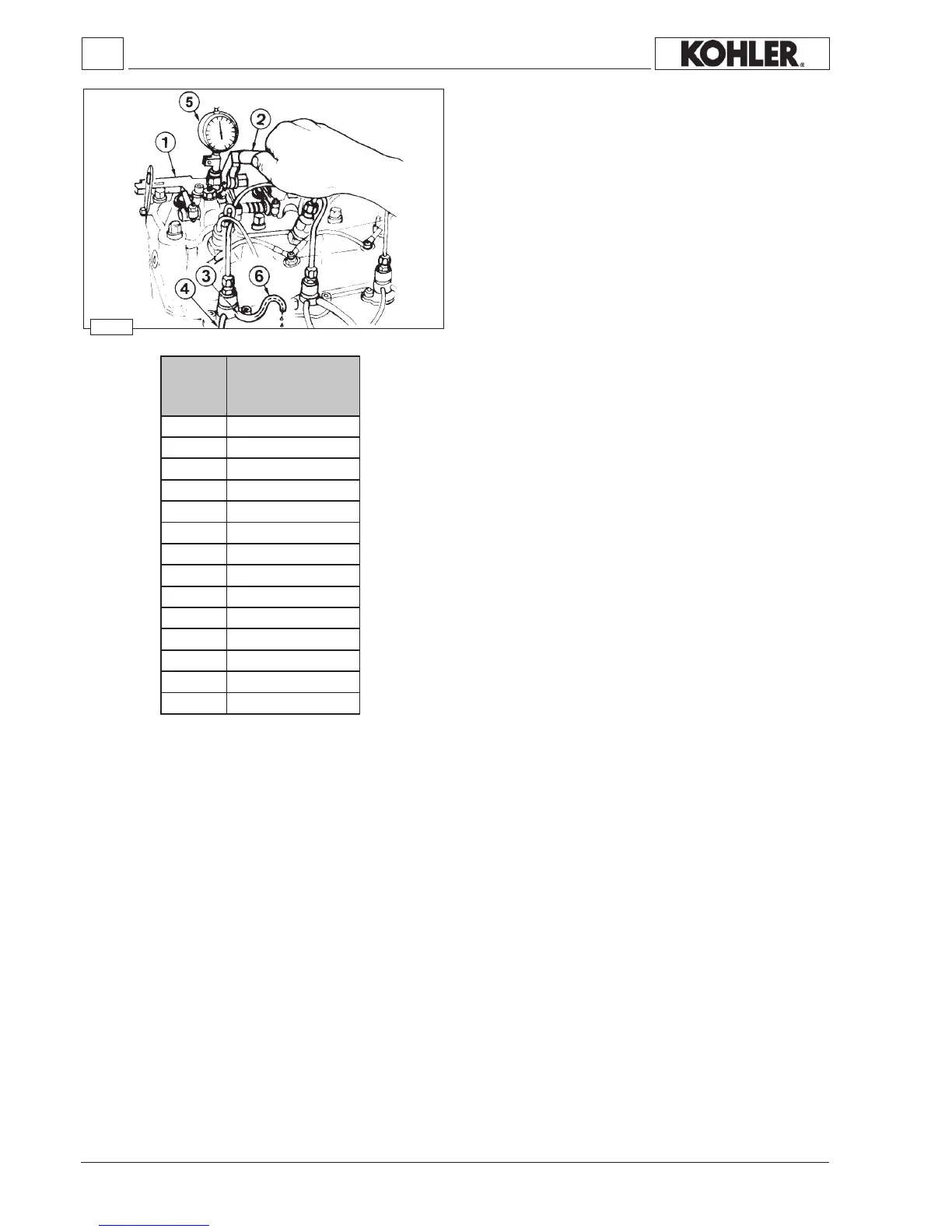

KDW

1603_2204_2204/T

(mm)

16° 2,27

15° 2,00

14° 1,74

13° 1,50

12° 1,28

11° 1,08

10° 0,89

9° 0,72

8° 0,57

7° 0,43

6° 0,32

5° 0,22

4° 0,14

3° 0,08

Fuel system

- Thesameoperationmustbecarriedoutoneachpump.

- Thedifferenceinadjustmentmustbelimitedtoabout1°.

- Disassemblethevariousequipment,removetherocker-armpinandputbackthepushrodsintheirseats.

Thenre-assembletherocker-armpin.

- Rotatethecrankshaftsoastopositionthepistonsathalfstrokeforthree-cylinderengines.

- Forfour-cylinderengines,placethepistonofcylindernumberoneat150°afterthetopdeadcentre(incrossoverstage).

- Therocker-armpinmustbefastenedindifferentstagessoastoallowtheoilinsidethetappetstobedrained,thusallowingthem

topositionthemselvescorrectly.

- Oildensityandambienttemperatureareimportantfactorsthatwillaffectthewaitingtime(about10')betweensuccessivefastening

operations.

- Hurried fastening can cause serious damage to the engine.

- Asaguidelinetoeachfasteningoperation,makesurethatthecupoftheupperspringbearingringdoesnottouchthevalve

stemoilsealingringttedontheguide.

- Thenaltorqueoftherocker-armpinis50Nm.

- Reassembletherocker-armcapandtheintakemanifold,tighteningthescrewstotheindicatedtorque.

Workshop Manual KDW 1603_2204_2204/T _ cod. ED0053029180 - 1° ed_rev. 00

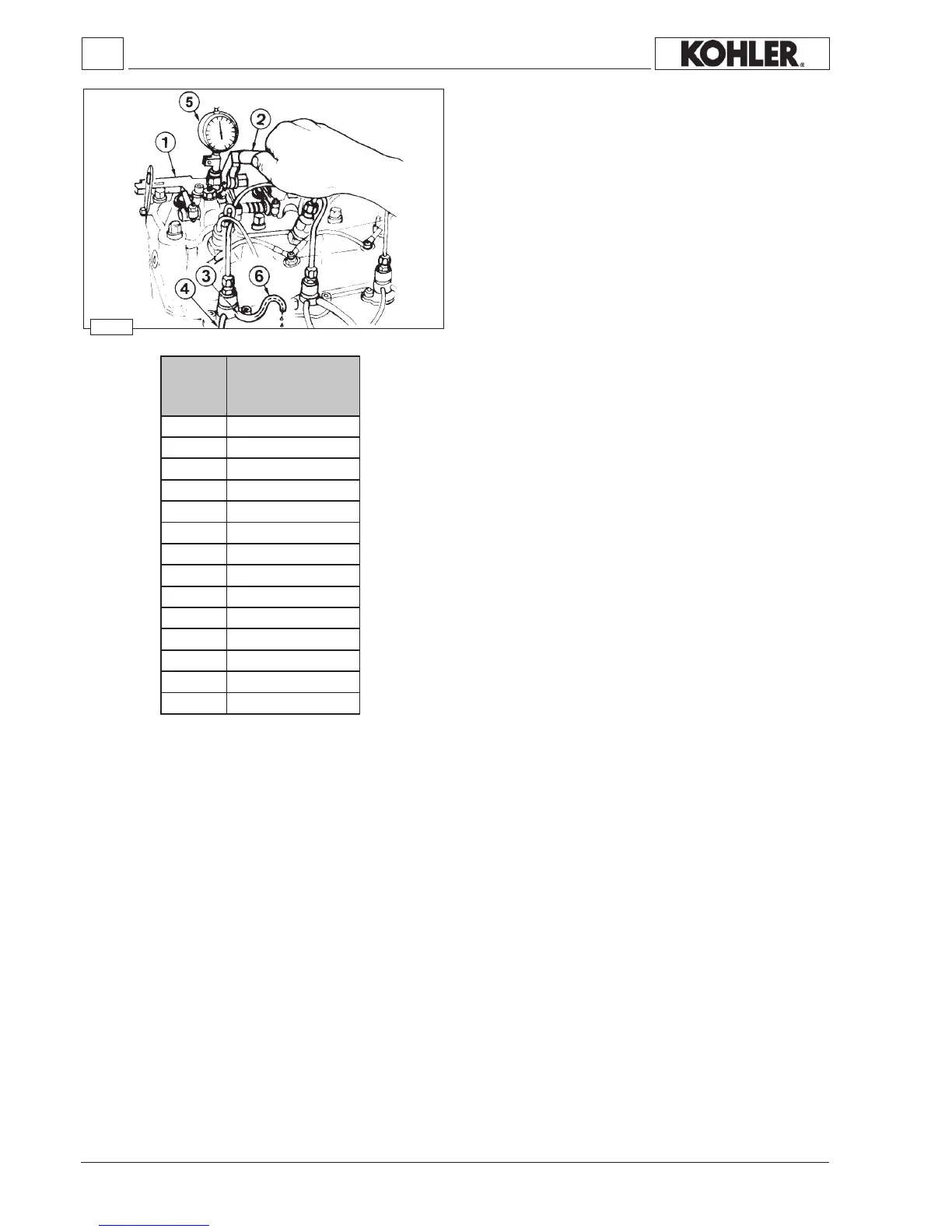

Checking low pressure injection timing for engines with

hydraulic tappets

Toverifythedeliverystartingpoint,therstoperationtocarryout

istodisconnectthenylontubesattheinlet4 andoutlet3ofevery

injectionpump.

Then,disassembletheairlter,theintakemanifoldandtherocker

armcap.

Nowdisassemblethewholerocker-armpinand,afterremoving

thepushrods,reassembleit.

Screwthespecialtool1serialnumber7107-1460-075(g.167)

ontothehead,makingsurethedialindicatortracer5setsagainst

theupperspringbearingringoftheintakevalve.

Useaprovisionalfueltank(e.g.deliverybalancingtool)togravity-

feedtheinjectionpumpconnectingittotheinletunion4;onthe

outletunion3tthetransparentnylontube6bythemeansofwhich

wemeasuretheoverow.

Placethepumpcontrolrodinthestopposition.

Operatethelever2of the tooltorotatethecrankshaftuntilthe

valvetouchesthepistoncrown.

ThisproceduredeterminestheexactTDC(topdeadcentreofthe

piston)ofthecylinderinquestion;resetthedialindicatorinthis

position.

Then rotate clockwise the crankshaft on the ywheel side until

dieselfuelbeginstoowoutofthesmallhoseonthepumpoutlet.

Nowchangetherotationdirectiontoanticlockwise.

Theowdiminishes.

Assoonasitstopsowing,thedeliverystartingpointisdetermined.

Then,lowerthetoollevertomakecontactbetweenthevalveand

thepistoncrownand,usingthedialindicator5,measurehowmuch

lowerthepistoniswithrespecttotheTDC(topdeadcentre)inmm.

Use the transformation chart (mm to degrees) to nd out the

correspondencebetweenmmmeasuredwiththedialindicator5

anddegrees.

Example KDW 1603-2204-2204/T: an advance of a=15°

correspondstoaloweringofthepistonwithrespecttotheTDC

(topdeadcentre)of2,00mm.

Loading...

Loading...