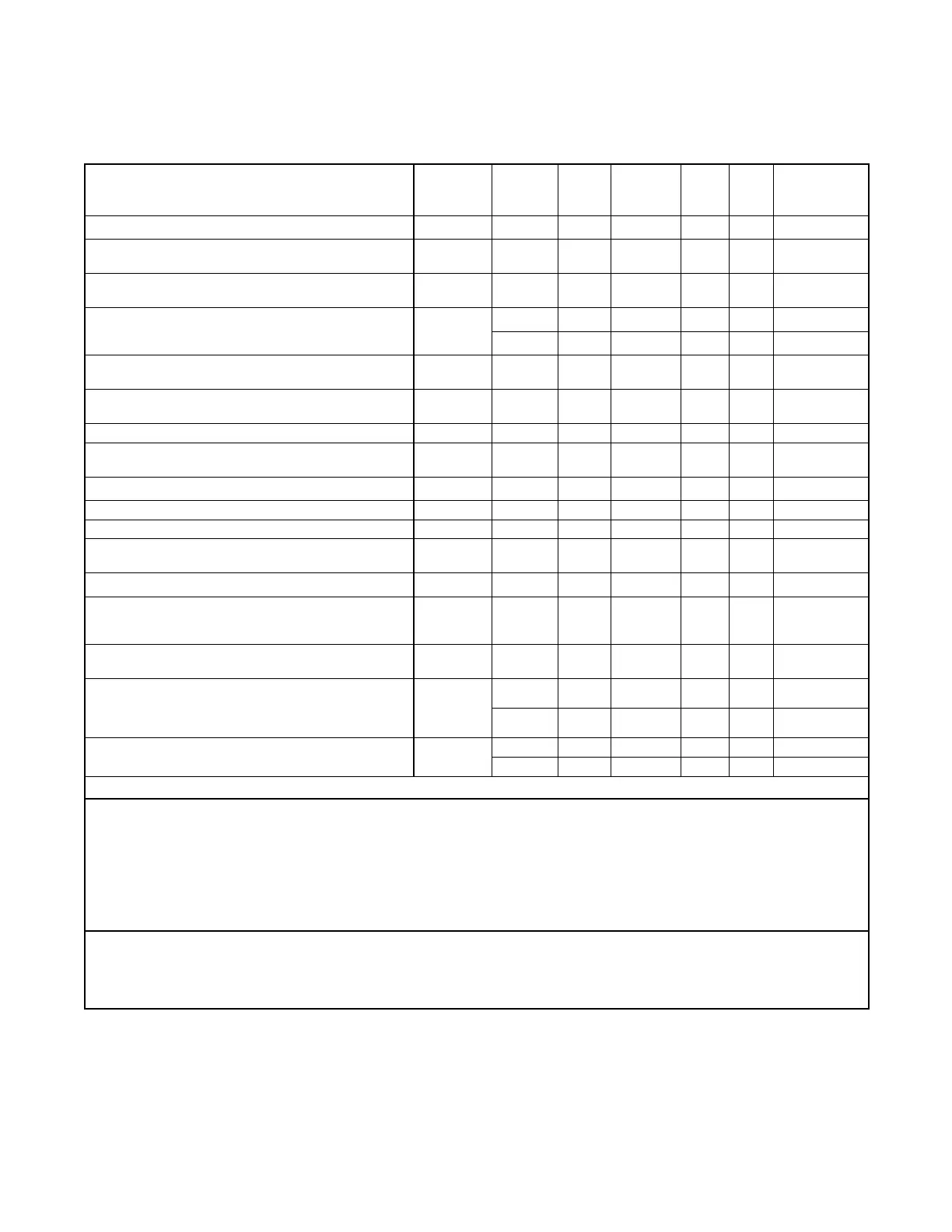

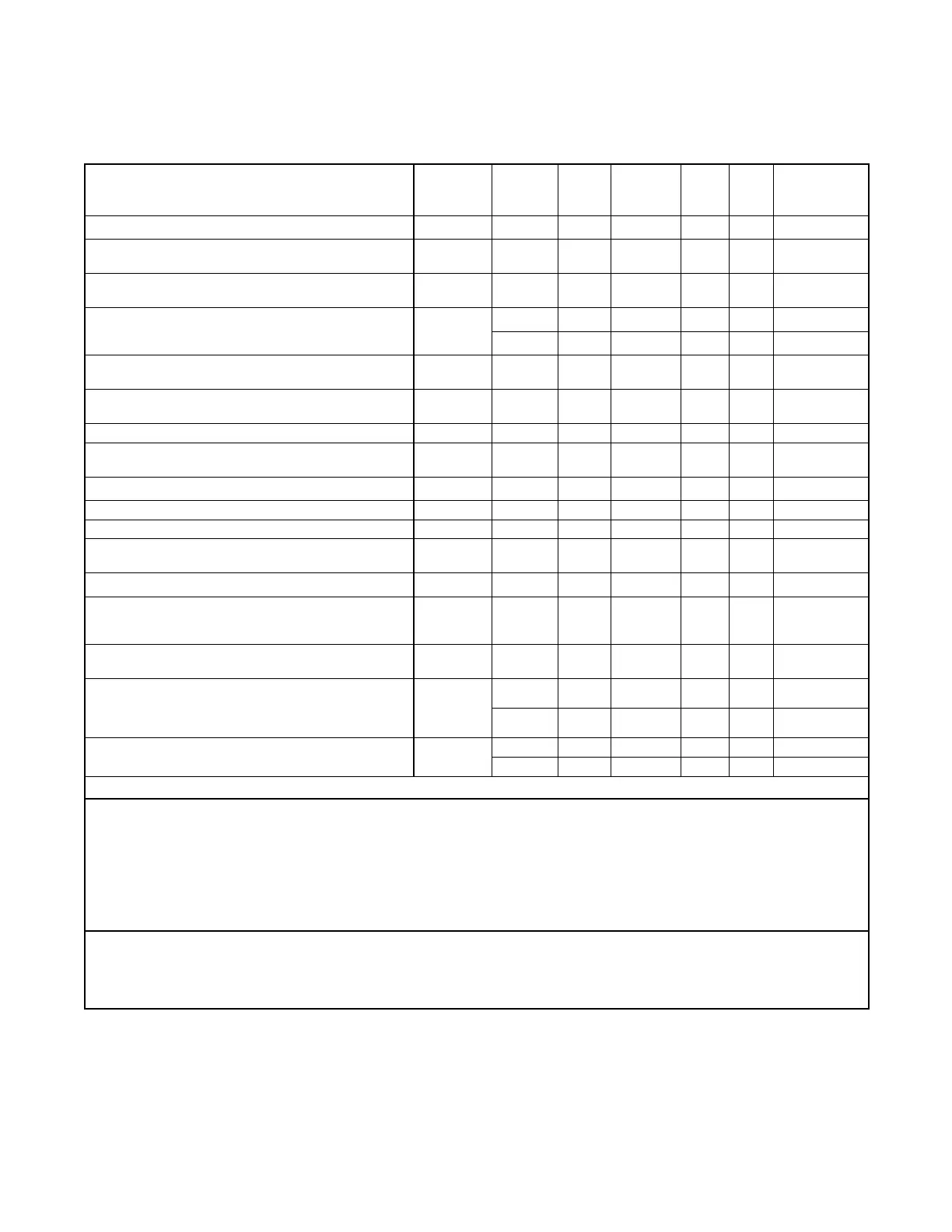

TP-6745 7/1014 Section 1 Scheduled Maintenance

1.5 Service Schedule

Follow the service schedule below for the

recommended service intervals. The transfer switch

operator can perform tasks marked by an X. Have an

authorized distributor/dealer inspect the switch annually

and perform all service marked by a D.

System Component or Procedure

See

Section

Visually

Inspect

Check

Adjust,

Repair, or

Replace

Clean Test

Interval

Electrical System

Check for signs of overheating or loose connections:

discoloration of metal, melted plastic, or a burning odor.

1.3 X X Y

Manually operate the power switching device and

lubricate, if necessary. *

1.3.3 D D Y

Check wiring insulation for deterioration, cuts, or

abrasion. Repair or replace wiring to regain the

properties of the original wiring.

1.3

X Y

D D D Y

Check the transfer switch’s main power switching

mechanisms’ mechanical operation and integrity.

1.3 D D D Y

Tighten control and power wiring connections to

specifications.

1.3 D D Y

Test wire and cable insulation for electrical breakdown. 1.4.3 D Every 3 Years

Check calibration of voltage-sensing circuitry and

setpoints, and recalibrate circuitry as necessary.

1.4.3 D D Every 5 Years

Control System

Exercise the generator set without load. 1.4.1, O/I/M X W

Test the transfer switch’s automatic control system. O/I/M X X M

Test all LED indicators, time delays, and remote control

systems for operation.

O/I/M D D D D Y

General Equipment Condition

Inspect the outside of the transfer switch for any signs

of excessive vibration, leakage, high temperature,

contamination, or deterioration.*

1.2 X X M

Check that all external hardware is in place, tightened,

and not badly worn.

1.2 X X X M

Inspect the inside of the transfer switch for any signs of

vibration, leakage, noise, high temperature,

contamination, moisture, or deterioration. Check for

metal discoloration, melted plastic, or a burning odor.*

1.3

X M

D D D Y

Check that all internal hardware is in place, tightened,

and not badly worn.

1.3

X M

D D Y

* Service more frequently if the ATS operates in extremely dusty or dirty areas.

See Section: Read these sections carefully for additional information before attempting maintenance or service.

Visually Inspect: Examine these items visually.

Check: Requires physical contact with or movement of system components, or the use of nonvisual indications.

Adjust, Repair, or Replace: Includes tightening hardware and lubricating the mechanism. May require replacement of components depending

upon the severity of the problem.

Clean: Remove accumulations of dirt and contaminants from external transfer switch’s components or enclosure with a vacuum cleaner or by

wiping with a dry cloth or brush. Do not use compressed air to clean the switch because it can cause debris to lodge in the components and

cause damage.

Test: May require tools, equipment, or training available only through an authorized distributor/dealer.

Symbols used in the chart:

O/I/M=See the transfer switch operation/installation manual.

X=The transfer switch operator can perform these tasks.

D=An authorized distributor/dealer must perform these tasks.

W=Weekly

M=Monthly

Q=Quarterly

S=Semiannually (every six months)

Y=Yearly (annually)

Loading...

Loading...