5 Function description

5.2 Pump unit structure

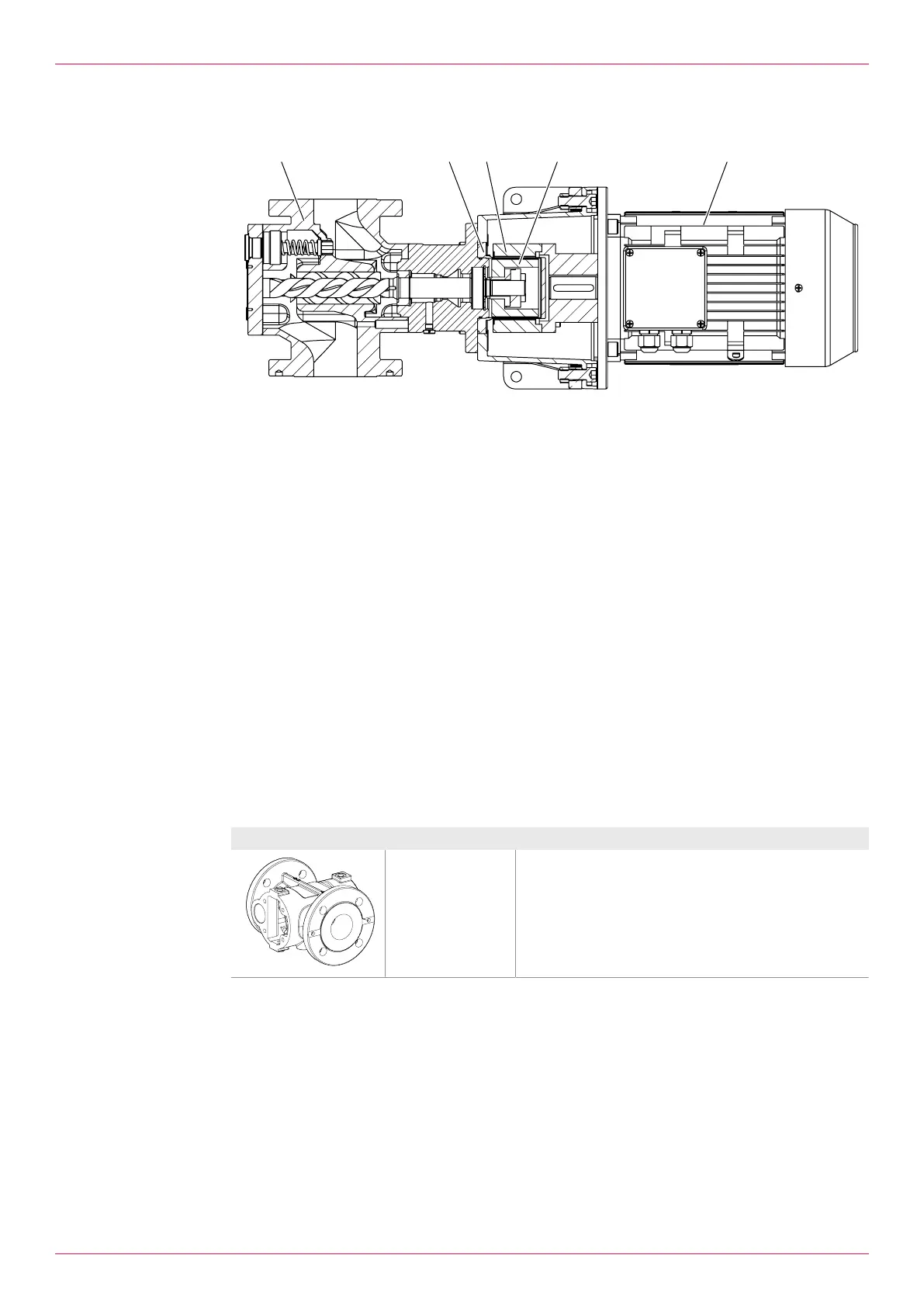

5.2 Pump unit structure

Fig.4: Pump unit structure

12 Pump 15 Inner rotor

13 Containment can 16 Motor

14 Outer rotor

5.3 Functional principle

Screw pumps are rotating pumps. Their displacement effect results from three rotating screws6 and11

and the enclosing pump housing3.

Radial support of the screw set is effected through the sliding contact in the pump housing that de-

pends on lubrication by the pumped liquid. Screw pumps are therefore not suitable for dry running and

can only be used up to specific pressure limits and viscosity limits. Due to the narrow tolerances pump-

ing of suspended solids is not possible.

Axial support of the main screw is effected by a deep-groove ball bearing. In order to reduce the pres-

sure, a balancing cylinder is mounted at the main screw. An integrated overflow valve protects against

excessive pressure that could cause housing parts to burst.

The default direction of the rotation of the screw set is clockwise viewed from the motor and is marked

on the pump flange by an arrow.

The flow direction is marked on the pump housing by two arrows.

5.4 Housing variants

Housing Type Description

KF/KV Flange arrangement: Inline flange PN16

10

OIK 09en-GB Edition 2019-11

Operating instructions

Loading...

Loading...