14 Troubleshooting

14.1 Possible faults

14 Troubleshooting

14.1 Possible faults

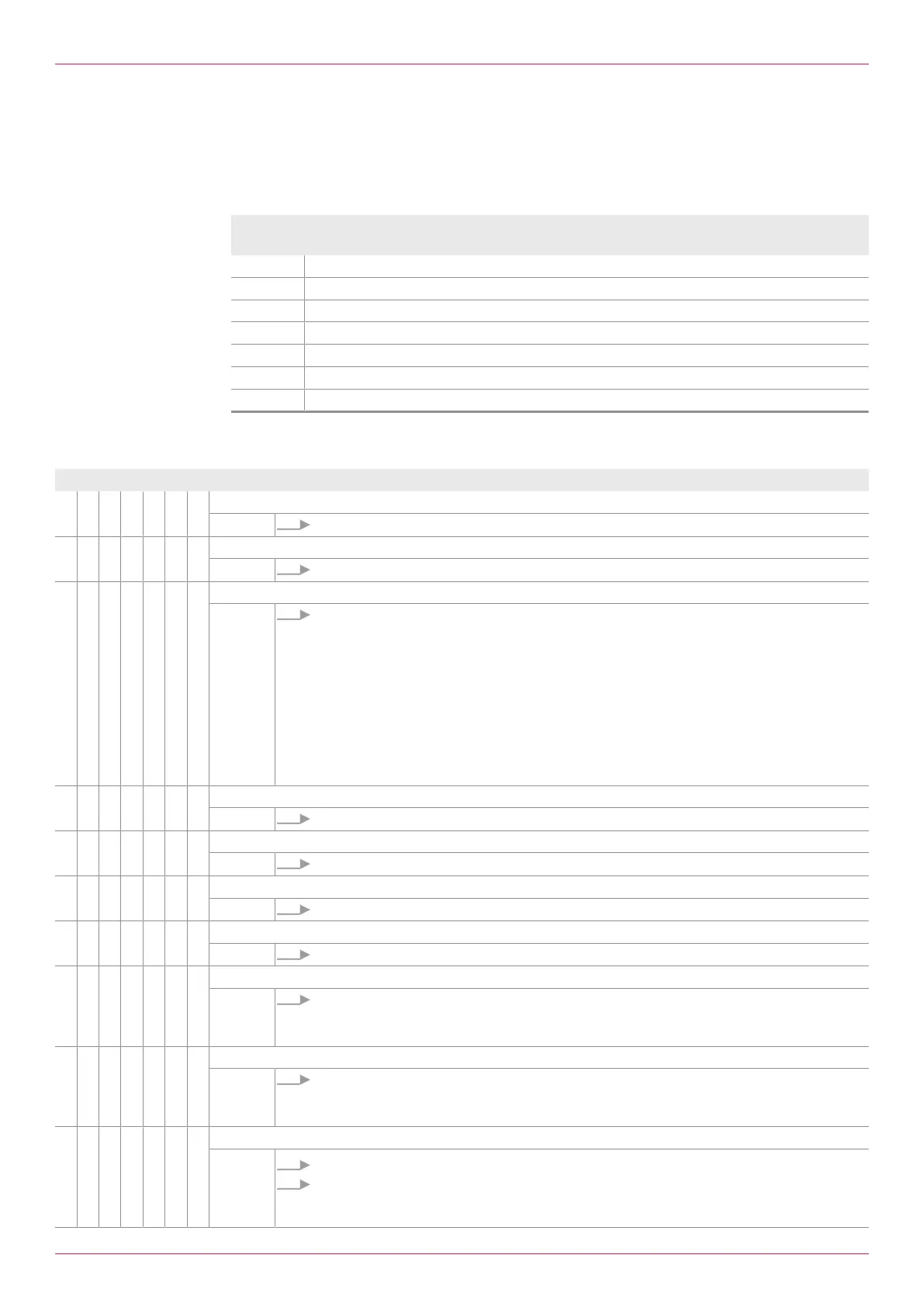

Faults can have different causes. The following tables list the symptoms of a fault, the possible causes

and measures for troubleshooting.

Identifica-

tion

Fault

1 No pump suction

2 Delivery rate too low

3 Pump too loud

4 Motor overload

5 Uneven delivery rate

6 Pump has seized

7 Magnetic coupling leaks

14.2 Troubleshooting

Fault identification Cause Remedy

1 – – – – – – Pump suction line closed

Check the shut-off devices. If required, open.

1 2 3 – 5 – – Parts soiled (filter, suction line, suction valve, strainer)

Clean parts.

1 2 3 – 5 – – Suction head too high

Reduce the level difference.

-or-

Reduce the line length.

-or-

Increase the line cross-section.

-or-

Heat up the pumped liquid.

-or-

Install a filter / strainer with a larger mesh width. Ensure that the permissible mesh width

is not exceeded.

1 – 3 – – – – Level in the intake container too low

Fill the intake container.

1 – – – – – – Too little pumped liquid in the pump

Fill the pump with pumped liquid.

1 – – – – – – Incorrect pump direction of rotation

Swop the two electrical connection phases Ä Connection,Page18.

– – – 4 – – – Differential pressure too high

Reduce the differential pressure.

1 – 3 4 5 – – Viscosity of the pumped liquid too high

Increase the temperature of the pumped liquid.

-or-

Decrease the speed.

– 2 – – – – – Viscosity of the pumped liquid too low

Reduce the temperature of the pumped liquid.

-or-

Increase the speed.

– 2 3 – 5 – – Airlock/gas in the pumped liquid

1. Test the pipe system for air admission, replace leaking parts.

2. Reduce the suction head.

-or-

Increase the inlet pressure.

38

OIK 09en-GB Edition 2019-11

Operating instructions

Loading...

Loading...