6 Transportation, storage

6.5 Storing the pump

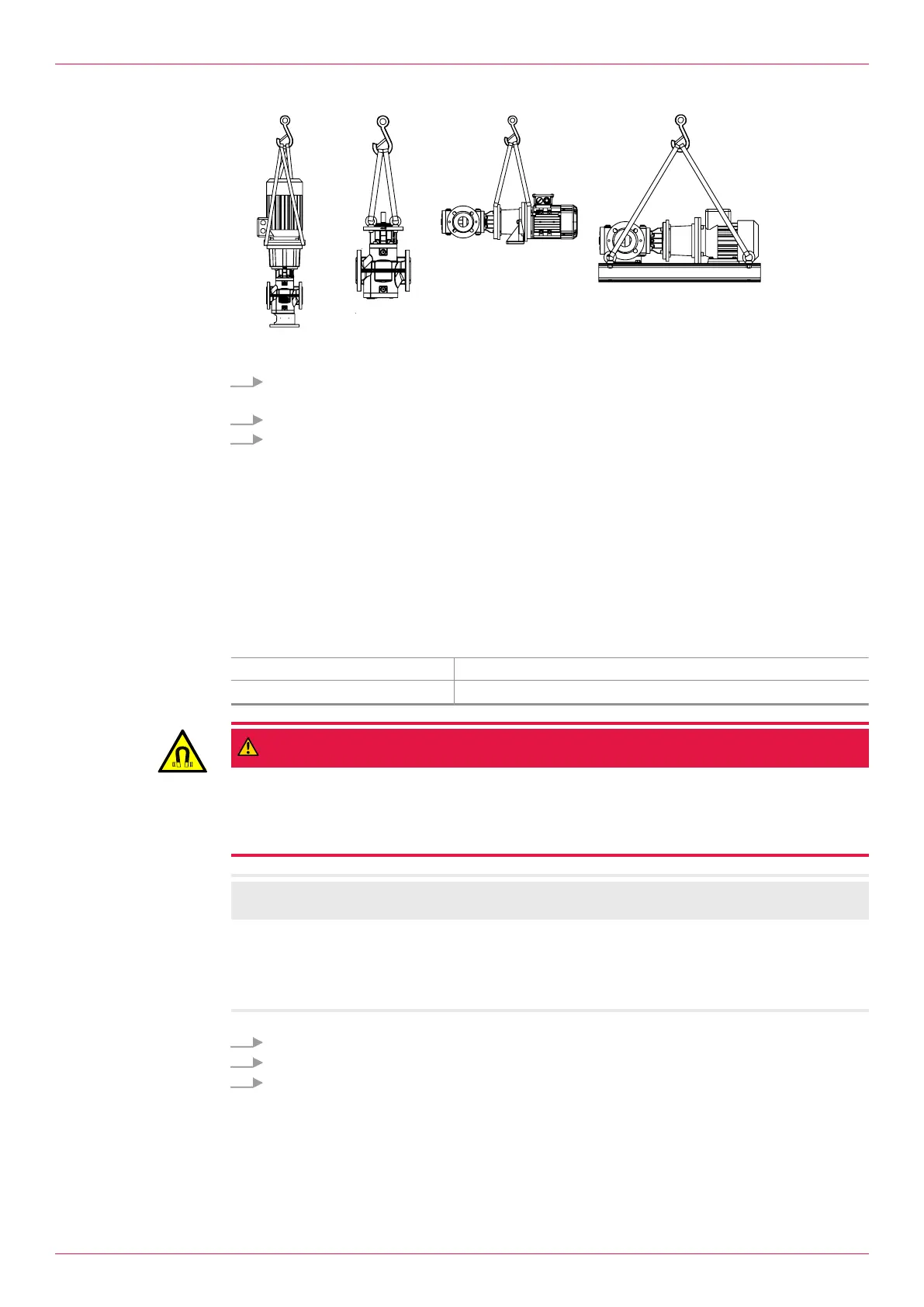

Fig.6: Fastening of hoisting equipment - principle diagrams

1. Attach the hoisting equipment to the pump/pump unit and tighten. Ensure that the centre of grav-

ity lies exactly under the crane hook.

2. Lift the pump/pump unit carefully and put it down shock-free.

3. Before loosening the transport belts ensure that the pump/pump unit is secured against tilting.

6.5 Storing the pump

During the test run, the internal components of the pump are wetted with test oil, which has a preser-

vative effect. Pressure connection and suction connection are closed with protective caps. Unless oth-

erwise specified, the outer surfaces of the pump are preserved with a single-coat PU-based two-com-

ponent paint.

The preservative applied at the factory will protect the pump for about six weeks, if it is stored in a dry

and clean location.

The manufacturer offers a long-term preservation for storage times of up to 60months. The pump is

additionally packed in hermetically sealing anti-corrosion paper.

Personnel qualification: o Transport personnel

Aids: o Mobile crane, forklift, hoisting equipment

DANGER

Magnetic field.

Risk of death for persons with cardiac pacemaker, metallic implant or neurostimulator.

► Under no circumstances may persons with cardiac pacemakers, metallic implant or

neurostimulator perform work on the pump/pump unit.

ATTENTION

Damage to equipment and corrosion if stored improperly and during longer standstills.

► Protect the pump against damage, heat, sunlight, dust and moisture.

► Protect against corrosion during longer standstill.

► Observe measures for storing and preservation.

1. Store cool and dry and protect against sunlight.

2. Ensure that the anti-corrosion paper is not damaged.

3. Observe the intervals for preservation Ä Preservation,Page14.

Operating instructions

OIK 09en-GB Edition 2019-11

13

Loading...

Loading...