10 Operation

10.3 During operation

1. Open the pressure gauge shut-off valve.

2. Read the operating pressure and close the pressure gauge shut-off valve.

10.3.2 Monitoring filters and/or strainers

Notice The manufacturer recommends protecting the pump against soiling by means of a filter and/or strainer

installed at the system end (mesh width 0.5mm). The degree of soiling of the filter and/or the strainer

can be monitored by means of a suction-side pressure gauge or a differential pressure indicator.

Notice The manufacturer recommends protecting the pump against soiling by means of a filter and/or strainer

installed at the system end. The degree of soiling of the filter and/or the strainer can be monitored by

means of a suction-side pressure gauge or a differential pressure indicator. Mesh width Ä Technical

data,Page8.

Personnel qualification: o Trained personnel

DANGER

Magnetic field.

Risk of death for persons with cardiac pacemaker, metallic implant or neurostimulator.

► Under no circumstances may persons with cardiac pacemakers, metallic implant or neurostimu-

lator perform work on the pump station.

ATTENTION

Damage to equipment through unsuitable filter and/or strainer.

► Observe the mesh width Ä Technical data,Page8.

1. After commissioning monitor the degree of contamination of the filter and/or strainer by means of

a suction-side pressure gauge or a differential pressure indication.

2. Additionally check the filters and/or strainers at a pressure drop on the suction side. Observe the

dimensioning data of the manufacturer of the filters/strainers.

3. Check the suction-side pressure every two weeks during running operation.

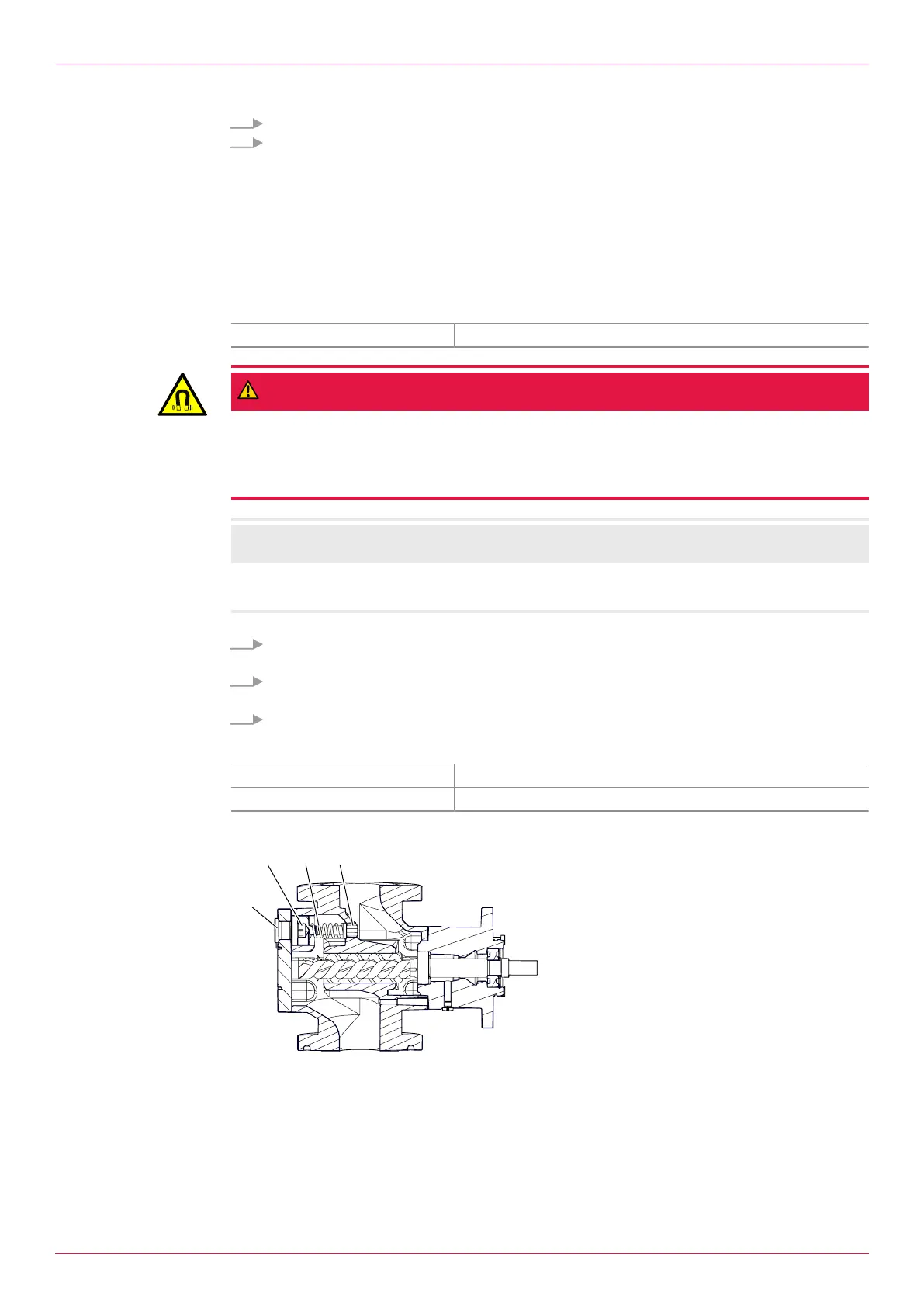

10.3.3 Adjusting the overflow valve

Personnel qualification: o Fitter

Aids: o Hexagon key

Notice The opening pressure of the overflow valve is set to 110% of the differential pressure in the factory.

Fig.10: Overflow valve

1 Screw plug

2 Adjusting screw

3 Pressure spring

4 Valve body

Operating instructions

OIK 09en-GB Edition 2019-11

25

Loading...

Loading...