12 Servicing

12.2 Wear

12.2 Wear

12.2.1 Signs of wear

The following table lists signs of progressive wear of individual pump elements:

Finding Cause Elimination

Increased running noises Incipient damage to bearing

Replace the ball bearing.

Reduction in the delivery rate or

pressure under constant

operating conditions

Advanced wear of screws and

housing

Replace the pump.

Tab.11: Signs of wear

12.2.2 Magnetic coupling

When using the pump in lubrication oil applications with a minimum purity class of 21/18/13 according

to ISO4406, an inspection at the latest after 5 years (400000h) is sufficient.

12.3 Replacing the overflow valve

12.3.1 Removing the overflow valve

Personnel qualification: o Fitter

Personal protective equipment: o Work clothing

o Protective gloves

o Safety boots

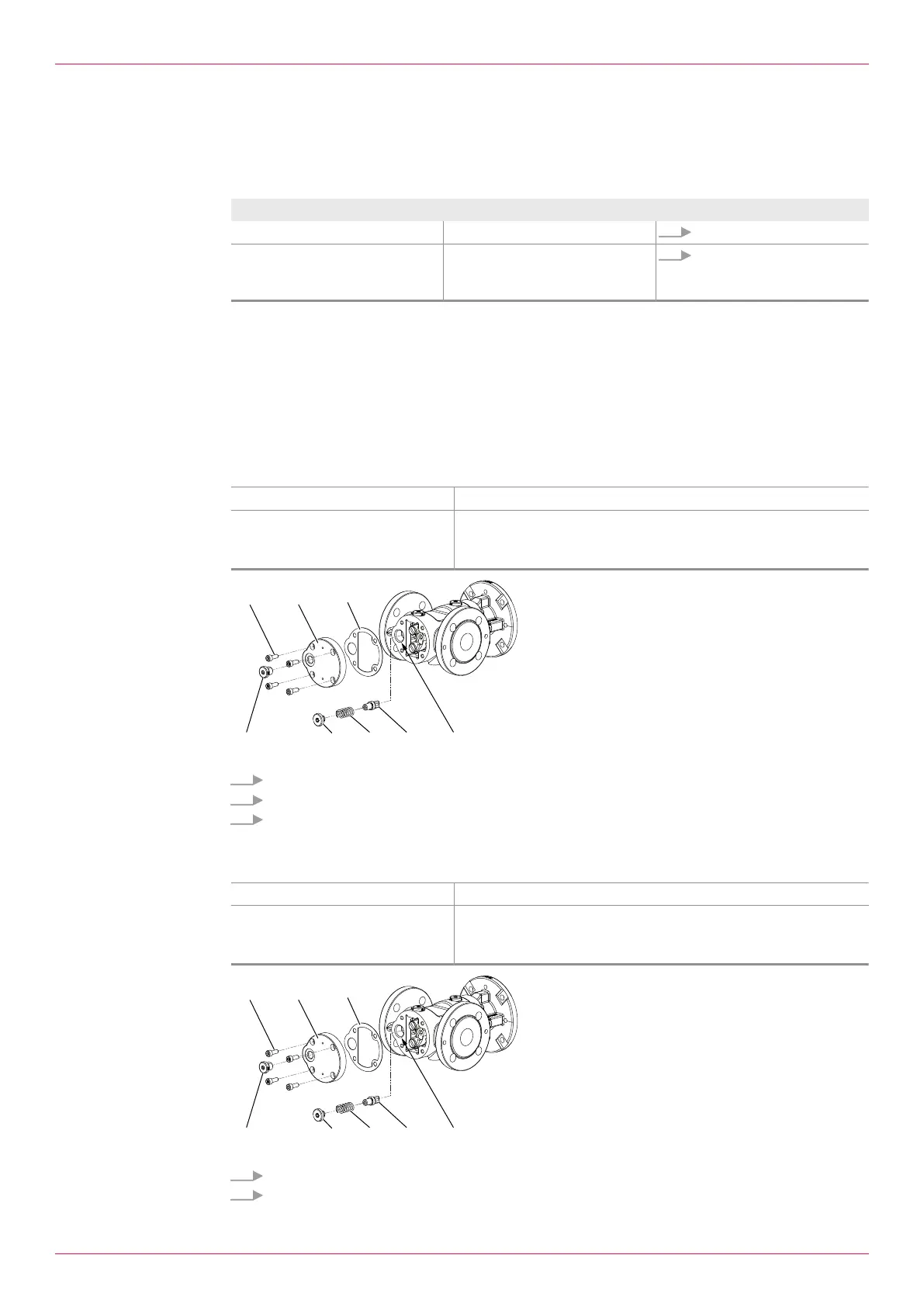

1. Remove the screw plug1 and socket screws2.

2. Remove the end cover3 and flat gasket4 from the pump housing5.

3. Carefully screw out the adjusting screw8 and remove the pressure spring7 and valve body6

from the pump housing.

12.3.2 Installing the overflow valve

Personnel qualification: o Fitter

Personal protective equipment: o Work clothing

o Protective gloves

o Safety boots

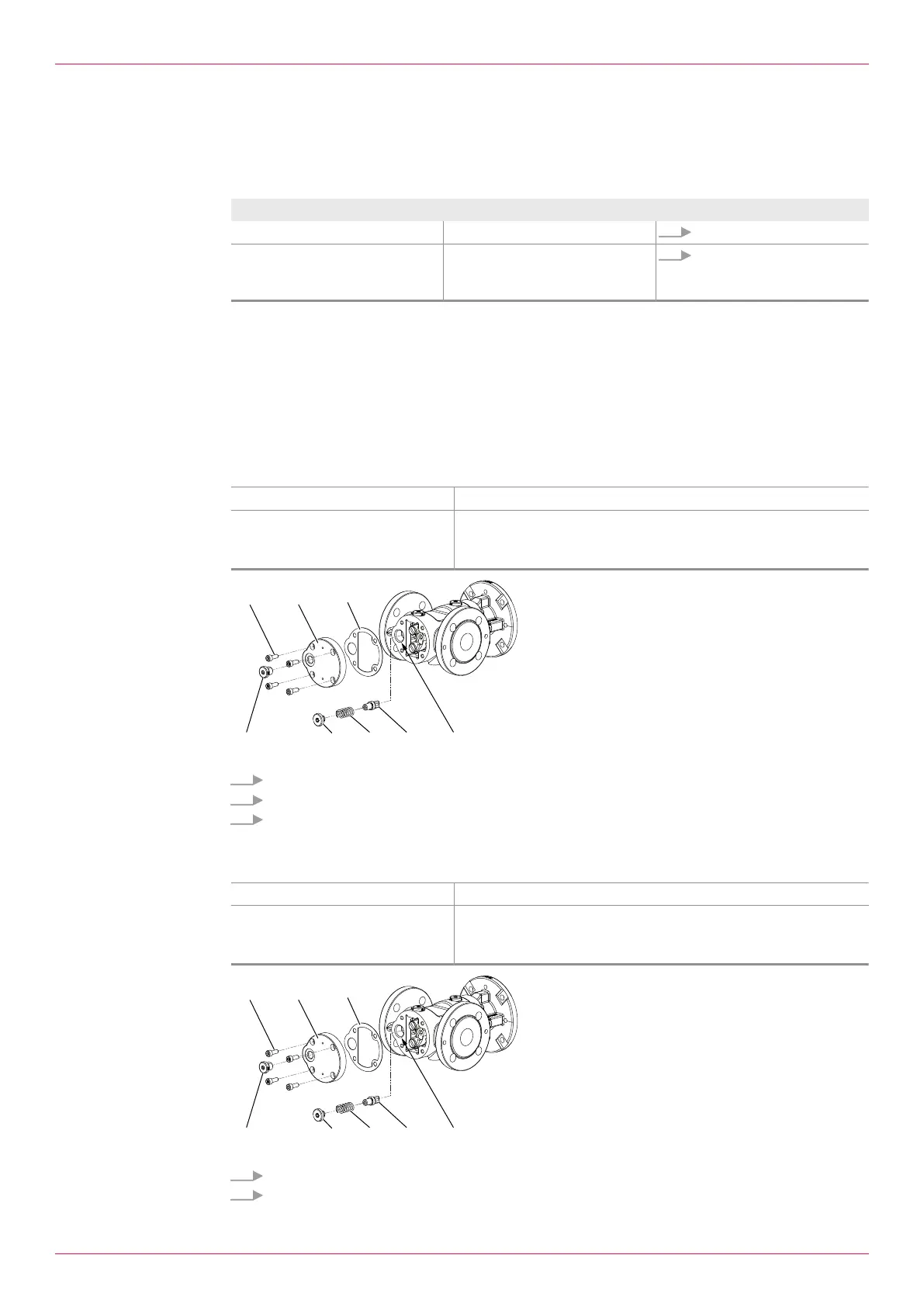

1. Clean the fitting surface carefully and bond a new flat gasket4 to the fitting surface.

2. Insert the valve body6, pressure spring7 into the pump housing5 and secure the pressure

spring with the adjusting screw8.

30

OIK 09en-GB Edition 2019-11

Operating instructions

Loading...

Loading...