12 Servicing

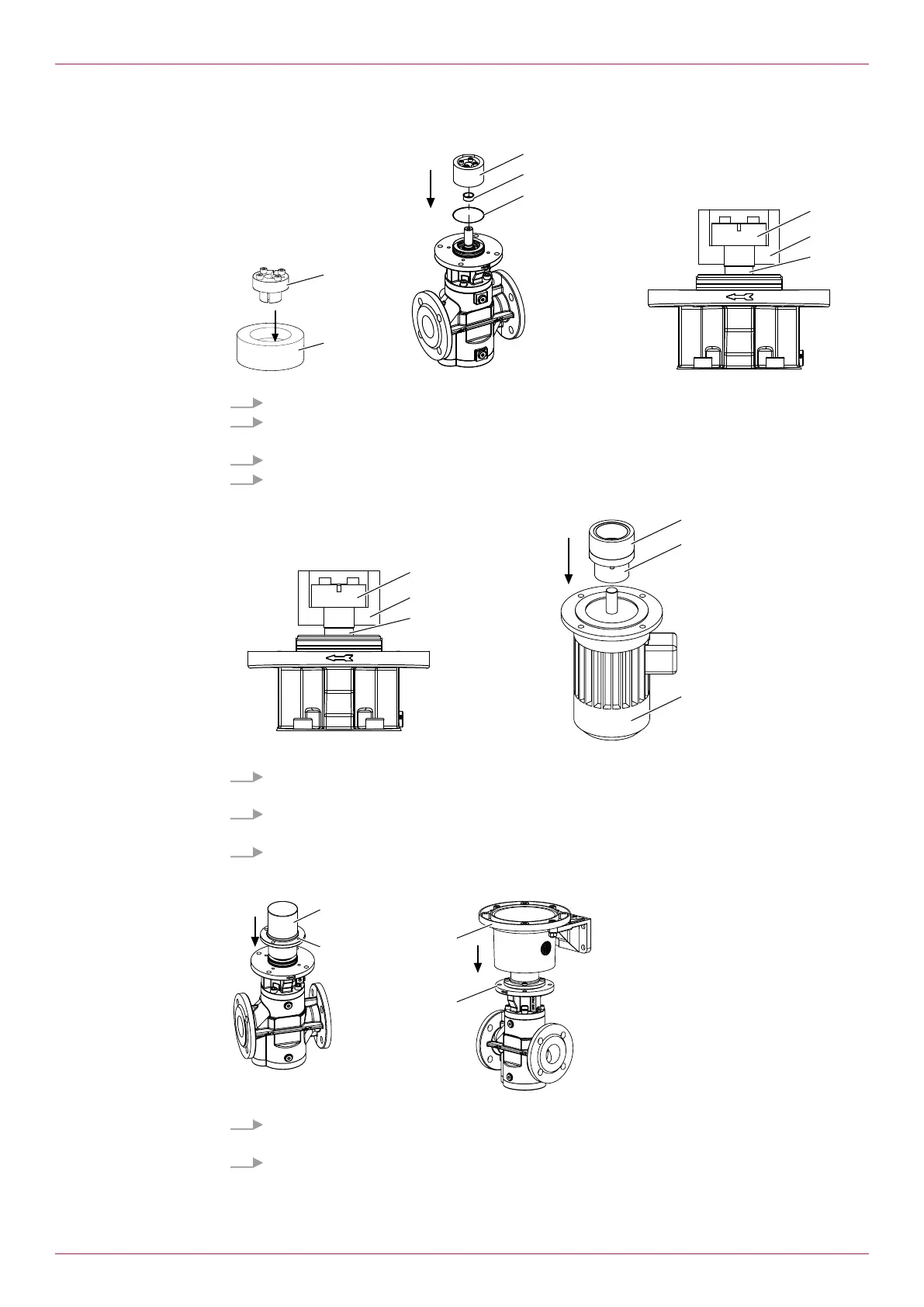

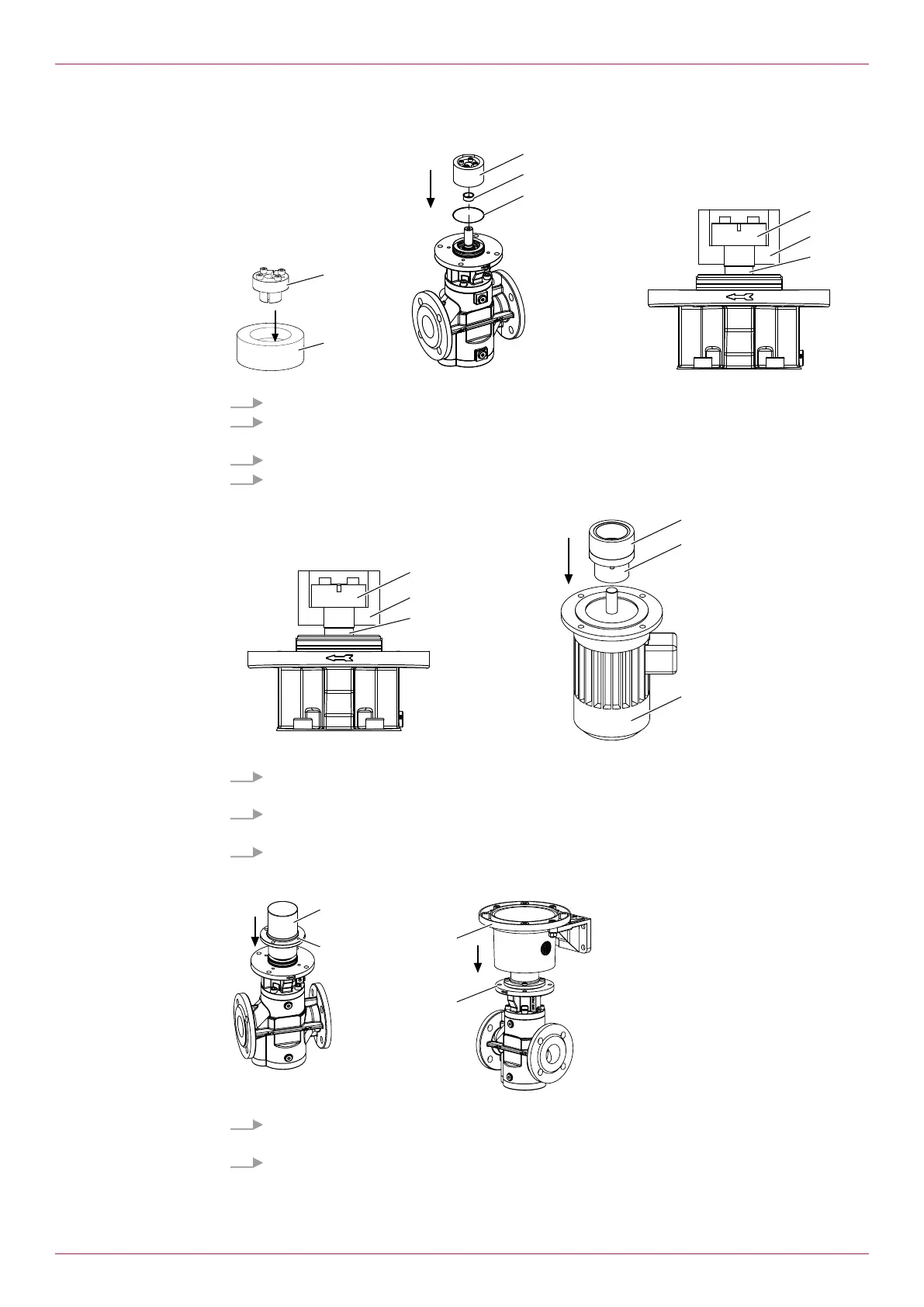

12.4 Replacing the magnetic coupling

Notice The inner rotor can be mounted more easily if it is heated to 80°C.

1. Carefully clean the contact surfaces of the inner rotor13, oil the tensioning element12 lightly.

2. Manually turn out the screws of the tensioning element by a few turns and insert the tensioning

element in the inner rotor.

3. Carefully clean the sealing surfaces.

4. Clean and lightly grease the O-ring15. Insert the O-ring and slide the distance sleeve14 onto the

pump shaft.

5. Place the inner rotor with the premounted tensioning element onto the pump shaft and tighten the

screws of the tensioning element crosswise by hand.

6. Check the position of the tensioning element: The tensioning element has to lie flat on the dis-

tance sleeve and inner rotor. Otherwise loosen the screws and reposition the tensioning element.

7. When the position is correct, first tighten the screws of the tensioning element with half the torque

crosswise. Subsequently tighten several times crosswise with the full tightening torque Ä Ap-

pendix,Page58.

8. Press the containment can11 onto the pump flange and tighten with socket screws10 using

torque.

9. Place the pump bracket3 on the pump and tighten the socket screws9 with torque.

Operating instructions

OIK 09en-GB Edition 2019-11

33

Loading...

Loading...