5 Installation at Site

22 of 82

Amarex

2573.820/02-EN

5.2 Checks to be carried out prior to installation

5.2.1 Preparing the place of installation

WARNING

Installation on mounting surfaces which are unsecured and cannot support the

load

Personal injury and damage to property!

▷ Ensure the concrete's compressive strength is sufficient (in accordance with

C35/45 in exposure class XC1 to EN206-1).

▷ The mounting surface must have set and must be completely horizontal and

even.

▷ Observe the weights indicated.

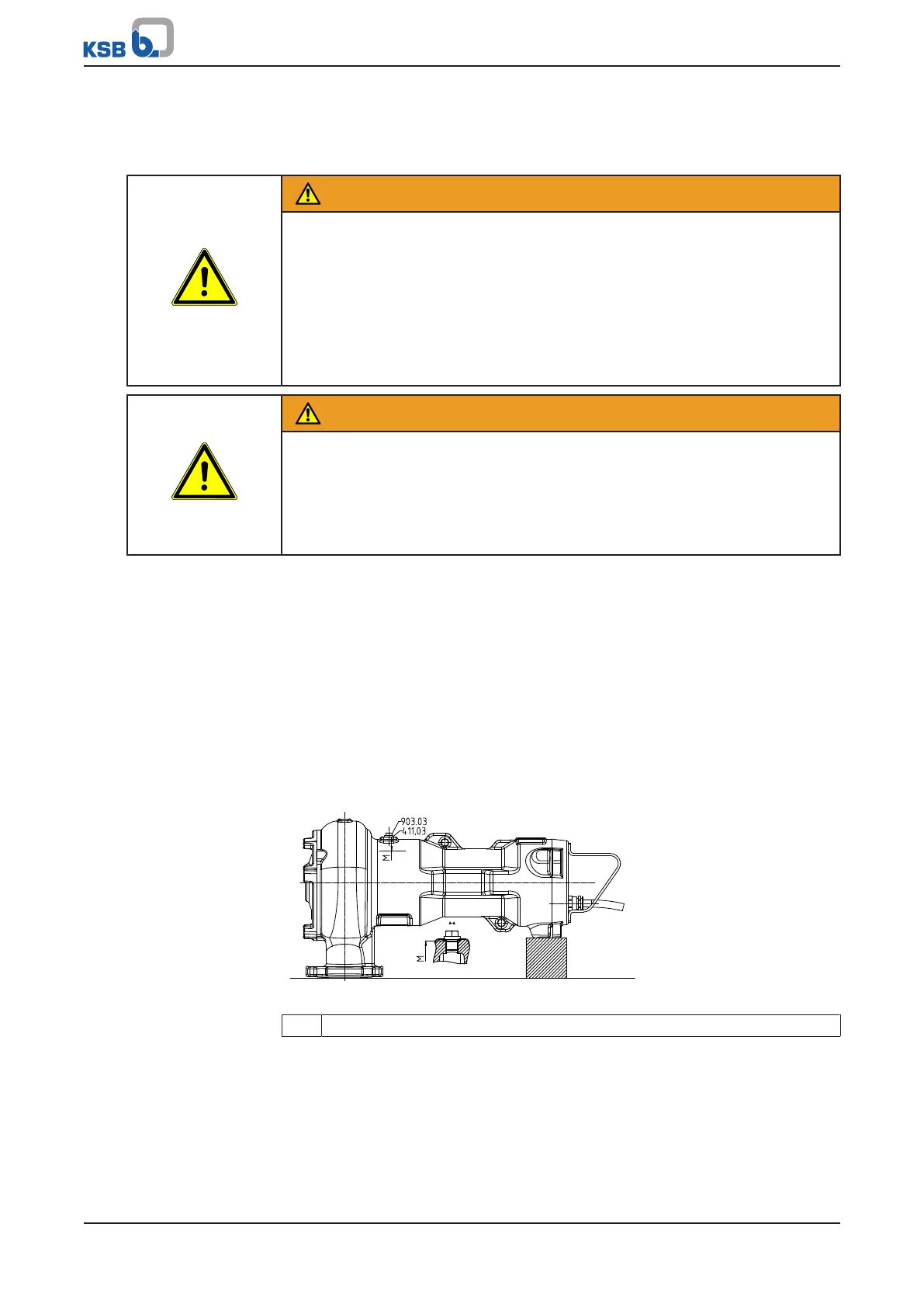

WARNING

Incorrect positioning/placing down

Personal injury and damage to property!

▷ Position the pump set vertically with the motor on top.

▷ Use appropriate means to secure the pump set against tilting and tipping over.

▷ Refer to the weights given in the data sheet/on the name plate.

Resonances Any resonances at the usual excitation frequencies (1x and 2x rotational frequency,

blade passing frequency) must be prevented both in the foundation and in the

connected piping, as such frequencies may cause extreme vibrations.

1. Check the structural requirements.

All structural work required must have been prepared in accordance with the

dimensions stated in the outline drawing/general arrangement drawing.

5.2.2 Checking the lubricant level

The lubricant reservoirs have been filled with an environmentally-friendly, non-toxic

lubricant at the factory.

1. Position the pump set as shown.

Fig.2: Lubricant level

M Optimum lubricant level

2. Unscrew and remove screw plug 903.03 with joint ring 411.03.

ð The lubricant level must be 38mm below the filler opening.

3. If the lubricant level is lower, top up the lubricant reservoir through the filler

opening until the indicated levelM is reached.

4. Screw in screw plug 903.03 with joint ring 411.03. Observe the tightening

torques.

Loading...

Loading...