5.2.3.1 Checking the fill level

WARNING

Drinking water/antifreeze mixture could escape

Hazardous to persons and the environment!

▷ Wear safety glasses and protective gloves when topping up, checking and

draining the motor fill.

▷ Observe the national health and safety regulations.

▷ Observe all legal regulations on the disposal.

WARNING

Screw plugs subjected to pressure

When opening screw plugs, liquid might spurt out!

▷ Wear safety goggles and protective clothing, if required.

▷ Open the screw plug slowly.

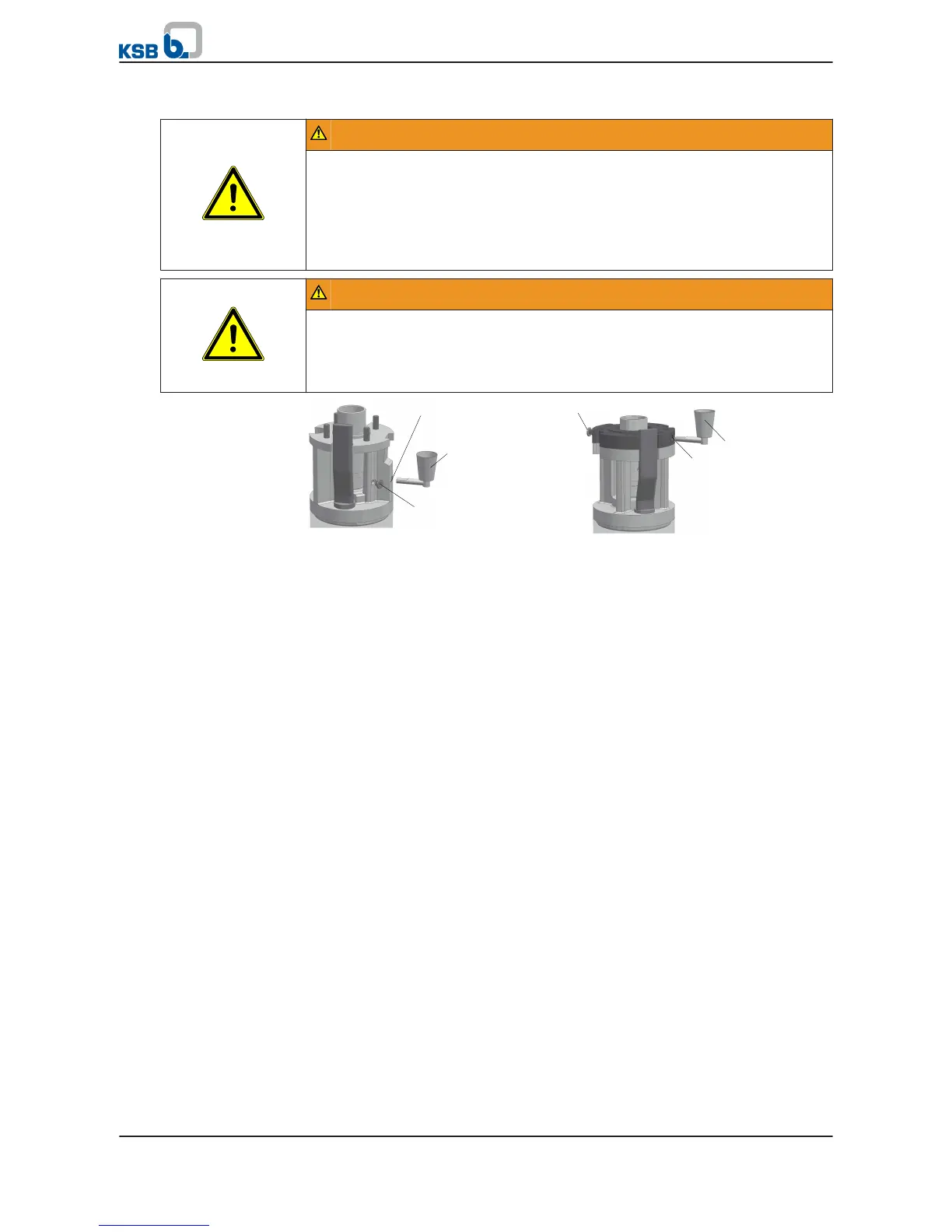

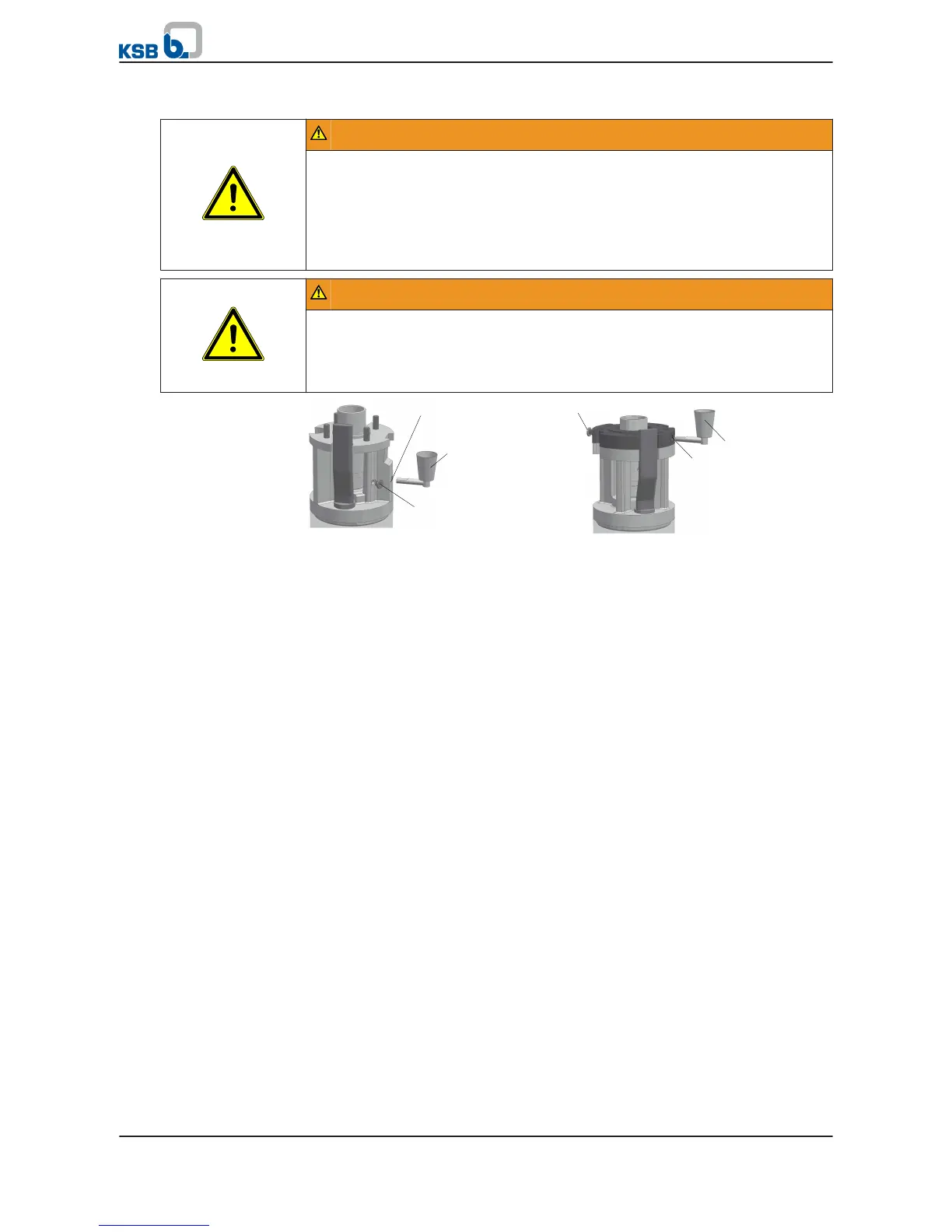

For motor type series T For motor type series V, X, Z, E

a) Filler opening

b) Vent opening

c) Filling funnel

a) Filler opening

b) Vent opening

c) Filling funnel

1. Set down the motor or pump set in a vertical position. Secure it against tipping

over.

2.

Undo the two screw plugs (a and b) and remove them together with the seal

elements.

⇨ If the liquid level is visible in one of the two openings, the motor fill is

sufficient.

⇨ If the fill level is not visible, fill the motor sufficiently. (⇨ Section 7.4.1 Page

48)

3. Screw the screw plugs (a and b) back in together with the sealing elements.

Check the screw plugs for tightness. Make sure that the contact faces are clean

and that the joint ring is inserted and free from damage.

1. Suspend the motor or pump set from a crane. Fasten the motor or pump set to

the floor and secure it against slipping.

2.

Carefully lower the crane to slightly tilt the motor or pump set.

3. Monitor the screw plugs for escaping fluid.

4. If required, fit new sealing elements.

5.2.4 Installing water storage tanks

If the pump set is intended for horizontal installation, the motor has to be fitted with

water storage tanks.

Checking the screw plugs

5 Installation at Site

24 of 64

UPA, UPZ, BSX

Loading...

Loading...