✓ The motor has been set down in a horizontal position on a level and solid

surface. It has been secured against rolling off.

✓ Position the motor with the connections for the water storage tanks at the

highest point.

✓ The water storage tanks are on hand.

✓ The motor fill has been checked with the motor in vertical position.

✓ Suitable liquid for topping up the motor fill has been prepared.

1.

Remove the screw plugs from the top and bottom of the stator case. Remove

the joint rings.

2. Insert the water storage tanks (59-33) with new joint rings (411.51) into the

stator and screw them in tightly.

3. Fill the water storage tanks with the specified liquid fill until they overflow.

4. Close both water storage tanks with a screw plug with integrated vent valve

(741) and joint ring (411.51).

5.2.5 Preventing backflow

CAUTION

Uncontrolled backflow of the fluid from the riser

Damage to the pump set!

▷ Prevent any uncontrolled backflow of the fluid handled with suitable means.

▷ Make sure that backflow of the fluid handled is slow and controlled, so that the

pump rotor does not start to rotate, e.g. by throttling the discharge-side gate

valve accordingly.

The submersible borehole pumps are generally fitted with an integrated non-return

valve.

On pump sets without non-return valve the operator must prevent any uncontrolled

backflow of the fluid, e.g. by structural means. Otherwise the pump could be

operated in the wrong direction of rotation and critical speeds could be exceeded.

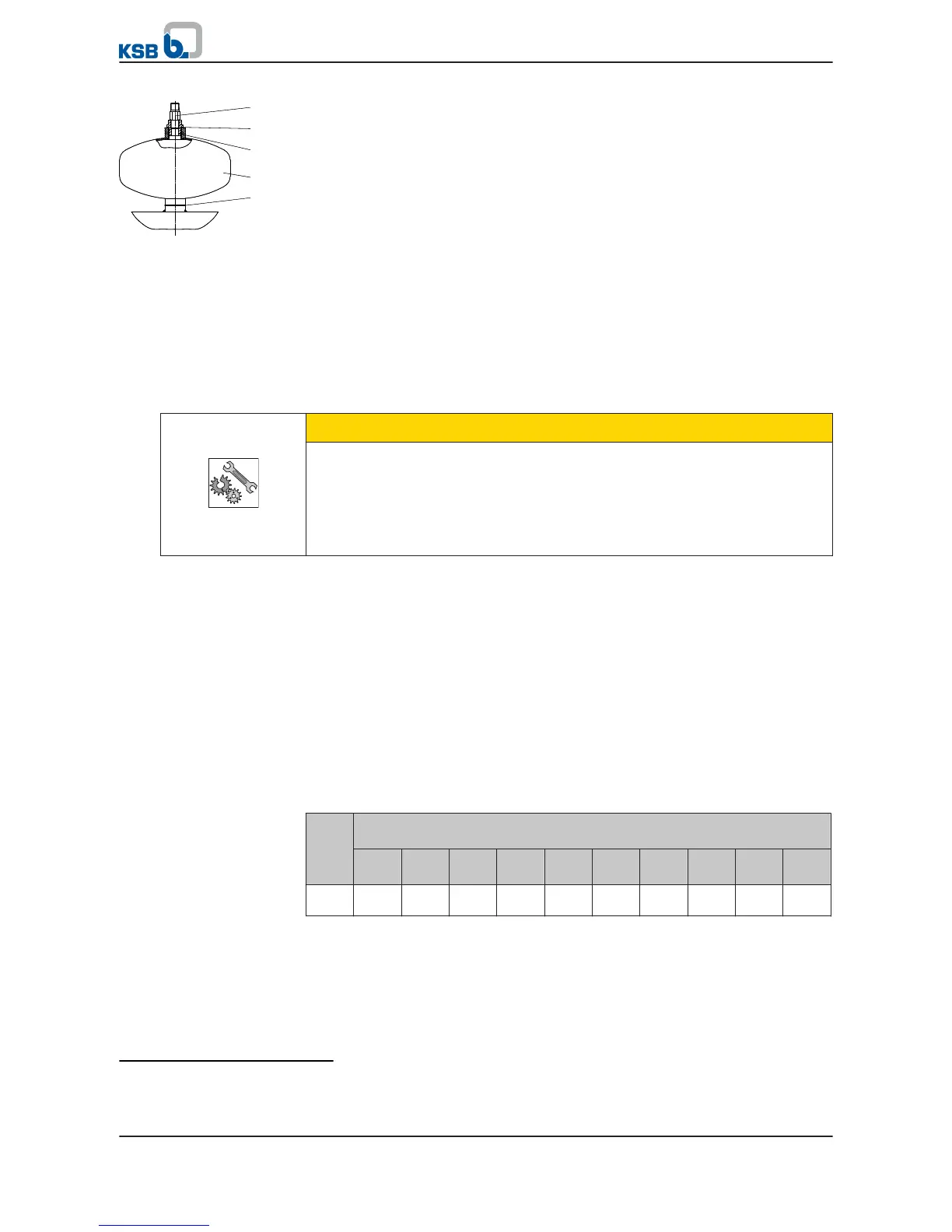

5.2.6 Calculating the total weight

Suitable lifting equipment (e.g. tripod, crane, etc.) is required for installing and

removing submersible borehole pumps. The load-carrying capacity of the lifting

equipment must be larger than the weight of the pump set + the riser

7)

+ the water

column

8)

in the riser + the power cable + the cable ties. For the weights refer to the

order documentation, the product literature of the sub-suppliers and the following

table.

Table 8: Weight of the water column per 1 metre of the riser

Pipe diameter [mm]

Pipe diameter [inch]

50

2"

80

3"

100

4"

125

5"

150

6"

200

8"

250

10"

300

--

350

--

400

--

Weigh

t [kg]

2 5 8 12 18 32 49 72 98 125

Loading...

Loading...